How is masterbatch plastic applied in 3D printing – A great technology in industry?

Masterbatch plastic is an obvious material in plastic industry nowadays. Masterbatch plastic has contributed in the development of human society by being the source for generating various products serving for both daily life and the industries. That’s the main reason for scientists to constantly pay efforts in studying how to improve this material and apply it into more fields.

One of the new areas that masterbatch plastic can be applied is 3D printing. We will show you how it is applied in 3D printing through the following article.

Why we should use masterbatch plastic in 3D printing?

In the current masterbatch plastic industry, almost every plastic molding technique requires the mold. These methods may be beneficial for mass production, however, the consuming cost in designing and constructing molds is very expensive. In addition, this process requires a lot of time and effort since the mold must be perfectly otherwise there must be another following step to correct every product and the industrial production systems will return into traditional hand-craft industry.

Not mentioned to these expenditures, each specific masterbatch plastic product requires a special and corresponding mold. This became a challenge for manufacturers whom want to produce a variety of products as they must spend more money to design and prepare more molds to establish new technique requires less equipment, less consuming costs in the purpose that they can fully optimize the production lines. This also causes an issue for anyone who just wants to produce a small amount of product or a prototype. In that circumstance, 3D printing is developed as an alternative method solving these problems.

Masterbatch plastic is one of the most important materials in 3D printing technology

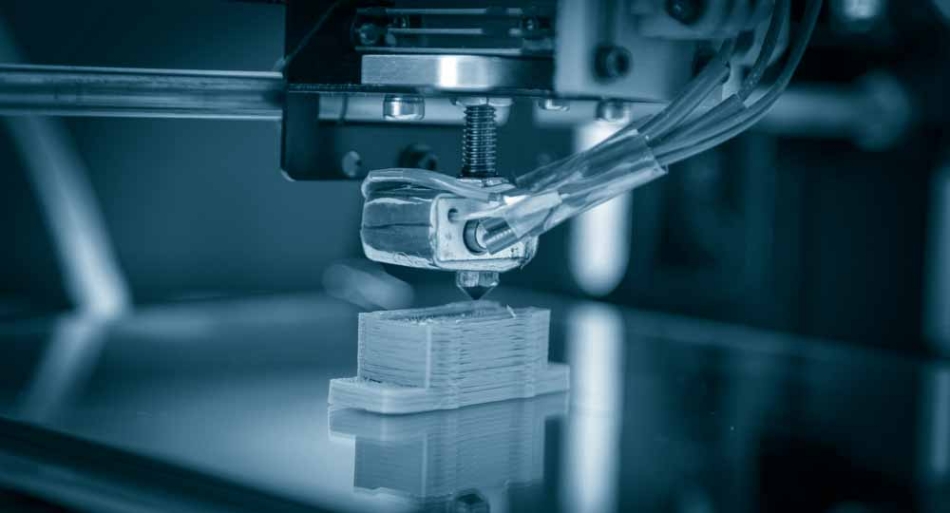

With 3D printing, masterbatch plastic manufacturers do not need to spend time and money to design and create various molds or special tools for their production. Instead, 3D printing machine is built up “transform” a digital design into a physical three-dimensional object. The operating mechanism of this machine is built each layer of the object at a time until the whole product is completed. This method allows manufacturers to generate thousands of distinct products with just one single machine.

Masterbatch plastic by far is the most common material of 3D printing technology, however this is not the only material used in this field. Other special materials such as metals, sands, composites and ceramics can also be 3D printed. Especially, metal and concrete are always expected to achieve more advantages and widely applied in this field. Most common application using 3D printing is generating masterbatch plastic prototyes, along with demanding parts and features for space engineering and aerospace field. Other technical industries such as automotive, aviation and construction are also the potential market for consuming 3D products.

Another advantage of 3D printing is that this technique can generate geometric complexity in shapes and forms of final product easily without charging any further cost or wasting too much scrap (like CNC machining). However, each masterbatch plastic type can only fit one or two 3D printing methods. This is depended on the charateristics of base resin used in the masterbatch composition.

Will 3D printing technology be the best solution for any masterbatch plastic products manufacturing?

Well, not really. 3D printing technology, as well any other typical technology, has its own advantages and disadvantages. Each technique was developed to solve a single (or several) problems, but likely no technique is able to solve all problems and fit any user. 3D printing is not an exception. Experts stated that 3D printing is a tool suitable for generate specially customized masterbatch plastic products/objects, prototypes or high-volume production.

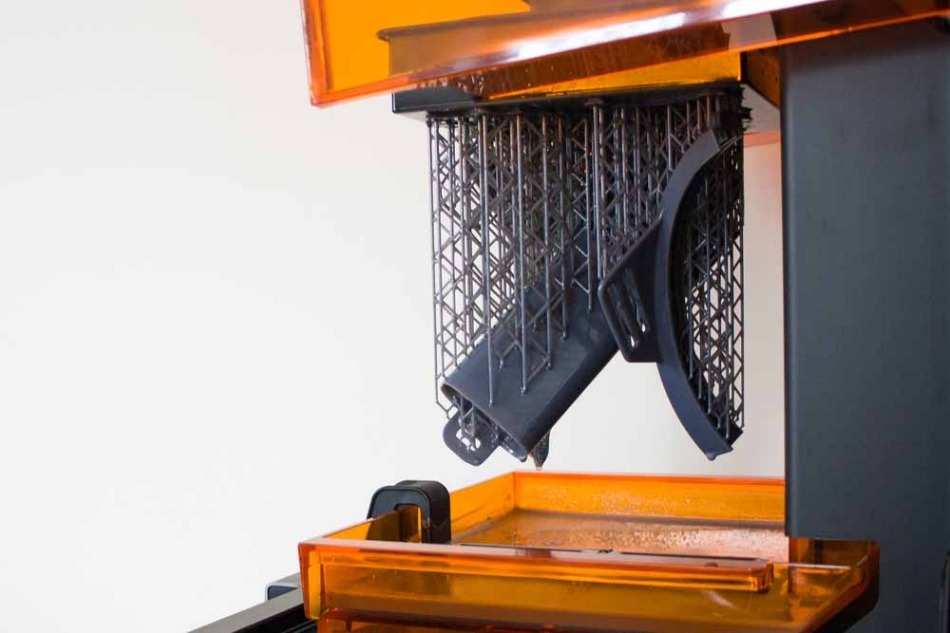

Limitations of 3D printing technology in masterbatch plastic manufacturing

First of all, 3D printing technology is less cost-effective if it is applied in large-scale production. Instead, it is perfectly suitable for making prototypes or production with small quantity (less than 100 products). Secondly, 3D printed products do not have good strength and physical properties in general as molded one. The thermal and impact resistance of 3D printed masterbatch plastic objects are generally reduced approximately 10 to 50% compared to the bulk material. They are weaker and more brittle since their structures are built by stacked up layers, not in a monolithic way like molding techniques. Last but not least, this technology requires post-processing and support removal steps. These auxiliary steps are needed since 3D printers are not able to add material on thin air so there must be supportive structures linking the building platform. These structures function as the pedestal for the printer to build hanging parts.