Does Plastic Conduct Electricity? How to Measure the Electrical Conductivity of Plastic?

Does plastic conduct electricity? For a very long time, the distinction between metals and plastics was obvious and simple to recall: metals conduct electricity, and plastics don’t. Now it is acknowledged that reality is more nuanced than that because under some conditions polymers may, in fact, carry electricity. Join us to learn about electrically conductive plastic and why doesn't plastic conduct electricity.

You may be interested in: Masterbatch - definition, applications, market trends and more

Plastics conduct electricity

1. Can Plastic Conduct Electricity?

1.1. Electrical Conductivity of Plastic

Plastics are categorized as insulating materials due to their surface resistivities, which are typically in the range of 1016 to 1017 ohms/sq. Electrically conductive base resins and electrically conductive fillers or reinforcing agents are combined to create the electrically conductive polymers that are now commercially accessible. A network of electrically conductive particles or fibers is required to make a material electrically conductive.

There are three distinct levels of plastic electrical conductivity that may be described for electrically conductive polymers:

- Dissipative Composites

- Conductive Composites

- ESD shielding Composite

2. Electrically Conductive Plastics

Will plastic conduct electricity? The answer is YES. In fact, some kinds of plastics can conduct electricity.

2.1. What Are Electrically Conductive Plastics?

Conductive polymers, also known as intrinsically conducting polymers (ICPs), are a class of organic polymers that are capable of conducting electricity. They are engineered materials that are filled with conductive additives to attain a specific level of electricity.

These compounds might have the conductivity of metals or could function as semiconductors. The most significant benefit of conductive polymers is that they can be processed, primarily by dispersion. Conductive polymers are often not thermoplastics, which means they are not capable of being thermoformed.

Carbon fillers, such as graphite, carbon black, and other conductive materials are often used in the conventional method for achieving this goal. The conductivity of conductive polymers is often measured between E4 and E12; nevertheless, this substance is merely semi-conductive.

However, they are organic compounds, the same as insulating polymers. They could have a high electrical conductivity, but their mechanical qualities are not comparable to those of other polymers that are commercially accessible. The organic synthesis techniques and the sophisticated dispersion techniques may be used to fine-tune the electrical characteristics of the material.

2.2. Why Use Conductive Plastics?

Conductive polymers have been used in commercial displays and batteries and show promise as antistatic materials. They are also touted as promising in the literature for organic solar cells, printed electronic circuits, organic light-emitting diodes, actuators, electrochromism, supercapacitors, chemical sensors, chemical sensor arrays, biosensors, flexible transparent displays, electromagnetic shielding, and perhaps as a replacement for the well-known transparent conductor indium tin oxide.

Microwave-absorbing coatings, especially radar-absorptive coatings on stealth aircraft, have been further used. Conducting polymers are quickly becoming popular in new applications because they provide materials that are more easily processed, have superior electrical and physical characteristics, and are less expensive. Abs plastic has high machinability and electrical conductivity, and it may be processed using traditional techniques.

In particular, the new nano-structured varieties of conducting polymers, with their greater surface area and improved dispersibility, advance this subject. According to research findings, conducting polymers with nanostructures in the form of nanofibers and nanosponges have much higher capacitance values than their non-nanostructured counterparts.

2.3. When to Use Conductive Plastics?

There are primarily two applications for conductive polymers in product design. The first use is to aid in the smooth operation of an electromechanical system, and the second function is to aid in the removal of undesired static from a piece of equipment. When making a selection of a material, it is essential to take into account the attributes necessary for the operation to be effective.

For instance, the majority of applications for handling paper media call for a certain set of attributes in the components that make up the system. These properties include hardness, tear strength, and coefficient of friction (COF). Even though metals are capable of providing significant levels of conductivity, it is quite unlikely that this material will give sufficient COF for the function to be adequate.

Because of this property, conductive polymers are often utilized in a wide variety of applications. Some examples of these uses include medical equipment, food processing systems, military and defense applications, and industrial applications.

Thanks to the flexibility of plastics, designers are allowed to create exactly what they have in mind, taking into account the material requirements, the intricacy of the component, and the volume demand.

Related: Antistatic Agents Overview (2022)

3. Why Can't Plastic Conduct Electricity?

Plastics, often known as man-made polymers, are moldable materials that are both flexible and resilient. A few synthetic polymers have been created with excellent conductivity for use as electrical conductors. The majority of plastics, however, exhibit considerable resistance to electrical current and are poor heat conductors because they are both thermal and electrical insulators.

Plastics do not conduct electricity due to several reasons. Consider a handful of these elements:

3.1. High Resistivity Level

The resistivity of a substance refers to how resistant it is to an electrical current passing through it. The measurement of electrical resistance is done using ohm-meters (Ωm). In insulators, electrical resistivity is high, with values in the range of.

Here are the levels of resistivity for several plastics:

- ASA/PC flame retardant - 14 1015 Ohm.cm

- ABS/PC blend 20% glass fiber - 16 1015 Ohm.cm

- CA Cellulose Acetate - 12 1015 Ohm.cm

- ABS high heat - 16 1015 Ohm.cm

The molecules of the plastic are connected in such a way that the atoms' electrons are filled. Plastics don't have any free electrons, which means they can't move about and conduct an electric current as metals can.

3.2. Low Thermal Conductivity

In general, poor thermal conductivity is characteristic of all insulators. That insulators make it harder for heat to pass through them is the meaning behind the phrase. Plastic is not a good conductor of electric current because the electrons inside it are not free to move about as they are in metal. Plastics help to concentrate the flow and protect against the loss of electricity.

3.3. Composition

The majority of plastics are organic polymers, meaning they include carbon, hydrogen, and often a few additional elements (chlorine in PVC, oxygen, nitrogen in nylon, and so forth). Plastics can be molded into a wide variety of forms due to the long chains of atoms that pack together nicely to produce a flexible solid. While certain polymers are thermosetting, which can only be formed once, others are thermoplastic, which can be heated and remolded several times.

3.4. Breakdown Voltage

Plastics do not carry electricity because of the breakdown voltage or the dielectric strength of the material. Any insulator will conduct electricity if subjected to too high voltages. When exposed to high voltages, certain materials, including plastics, lose their insulating qualities. This change occurs at a voltage known as the breakdown voltage. For insulators, there are many degrees of breakdown voltages.

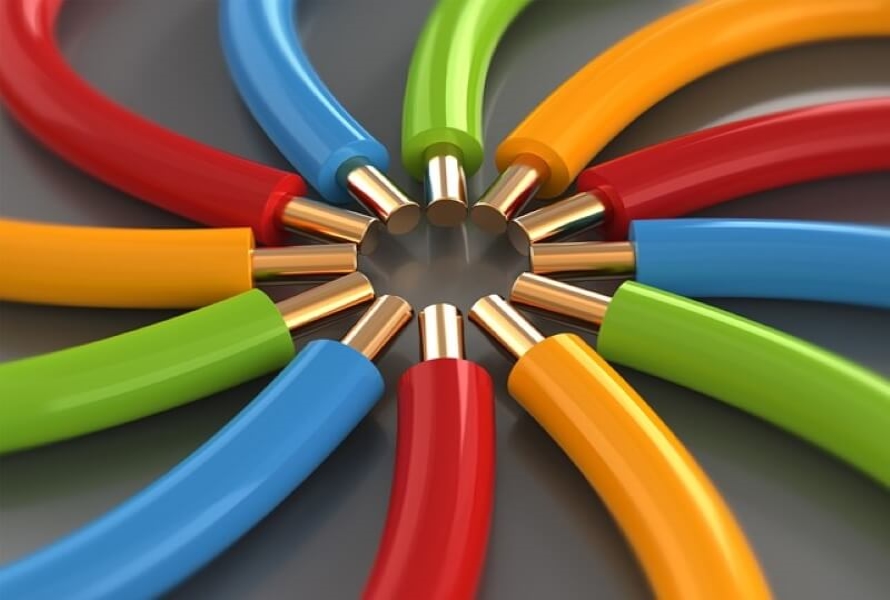

3.5. Applications

Several polymers are utilized as thermal insulators, such as vinyl siding and Styrofoam coffee cups. Plastic's capabilities as an electrical insulator also make it helpful for wrapping wires; for example, electrical tape is commonly produced from a kind of plastic called vinyl. Plastic's properties as an insulator also make it ideal for packaging electronic components.

However, in recent years, several plastics have been purposely developed to act as electrical conductors. Polyacetylene and polypyrrole are only two examples of polymers that have recently been purposefully created to act as electrical conductors.

4. The Bottom Line

Does plastic conduct electricity? Is plastic electrically conductive? As a result of the organic polymers that make up plastics, they are poor electrical conductors. For an electric current to go across a material, there must be free electrons or charged ions. However, there are still some types of conductive plastics with special applications.

If you would like to know more details about our filler masterbatch product in particular, as well as our other masterbatches, please fill out this form or contact us via email/phone number. We are happy to answer all your product questions and concerns!