Filler compound has become a cornerstone in modern plastics manufacturing, not only because it lowers raw material costs but also because it enhances efficiency, stability, and sustainability. For businesses aiming to balance quality with profitability, understanding why filler compound is considered cost-saving is essential.

1. Introduction to Filler Compound

Plastics manufacturers today face increasing challenges: rising raw material prices, pressure to reduce carbon footprints, and strict quality standards from customers. Against this backdrop, filler compound has emerged as a practical solution that addresses both financial and operational concerns.

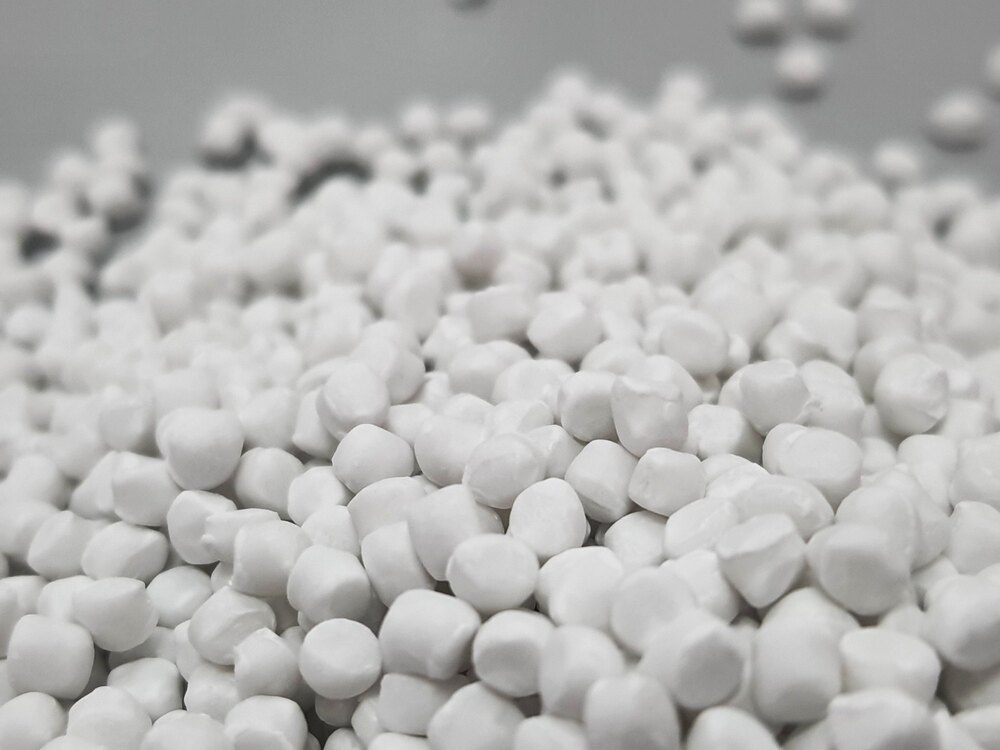

At its core, filler compound is a pre-compounded mixture of resin, mineral fillers (like calcium carbonate or talc), and processing aids. Instead of relying entirely on expensive virgin polymers, manufacturers can integrate filler compound into their production to significantly cut costs while maintaining — and in some cases even improving — product performance.

For decision-makers in the plastics industry, this means one key thing: filler compound is more than just an additive; it is a cost-optimization strategy that safeguards competitiveness in volatile markets.

By the end of this article, you will understand:

- What filler compound is and how it differs from other solutions.

- Why it is considered cost-saving across various applications.

- Real-world examples of its economic and sustainability benefits.

What is a Filler Compound?

2. What is a Filler Compound?

2.1. Definition and Basic Composition

A filler compound is a ready-to-use blend in which polymers are combined with mineral fillers and compatibilizers. The most common fillers include:

- Calcium carbonate (CaCO₃): The most widely used filler, known for its low cost and ability to improve stiffness.

- Talc: Adds heat resistance and dimensional stability.

- Barium sulfate: Provides density and surface finish improvements.

Unlike filler masterbatch, which is a concentrated mixture requiring dilution during processing, filler compound is pre-engineered to be directly processed, saving manufacturers additional blending steps.

This ready-to-use design ensures consistent quality, simplifies supply chains, and makes it easier for factories to maintain efficiency without constant adjustments.

2.2. Main Applications Across Industries

Filler compounds are versatile and widely applied across industries:

- Packaging films: Used in blown and cast films for bags and liners, where cost savings are critical.

- Injection molding: Found in caps, household goods, and automotive parts.

- Blow molding: Ideal for containers and bottles requiring durability.

- Construction plastics: Pipes, sheets, and profiles that demand rigidity and dimensional stability.

According to Grand View Research, the global polymer filler market size was valued at USD 57.33 billion in 2023 and is projected to grow at a CAGR of 5.0% from 2024 to 2030.

Filler compounds are versatile and widely applied across industries

3. Why Filler Compound is Considered Cost-Saving

The main reason manufacturers adopt filler compounds is clear: they directly reduce costs without sacrificing performance. Let’s explore how.

3.1. Replacing Virgin Resin

Virgin polymers such as polypropylene (PP) and polyethylene (PE) are expensive and subject to frequent price fluctuations. By partially substituting virgin resin with filler compound, manufacturers can reduce material costs by 20–40% per kilogram of output.

For example, in packaging film production:

- 1 ton of PP resin may cost around $1,200.

- By replacing 30% with a CaCO₃ filler compound costing $600/ton, the blended cost drops to roughly $960/ton.

This simple substitution demonstrates immediate savings, especially in large-scale operations where raw materials account for more than 60% of total production costs.

3.2. Enhancing Production Efficiency

Filler compound also improves efficiency by influencing how materials behave during processing, with fillers like CaCO₃ can lower energy consumption in film extrusion by up to 15%

- Faster heat transfer: Mineral fillers conduct heat better than pure polymers, leading to shorter cooling times.

- Improved dispersion: Ensures smoother extrusion and fewer processing defects.

- Reduced energy demand: Optimized melt flow decreases the electricity required for extrusion or injection molding.

3.3. Improving Mechanical Properties

Far from being just a cheap substitute, filler compounds also improve certain physical properties:

- Increased stiffness: Essential for packaging that requires rigidity.

- Dimensional stability: Less shrinkage during cooling, which means more consistent product sizes.

- Improved surface quality: Higher opacity and better printability for films.

By extending product life cycles and minimizing the need for frequent replacements, filler compound helps businesses save on both production and post-production costs.

3.4. Reducing Waste and Scrap

Manufacturers constantly battle scrap rates caused by shrinkage, warpage, or uneven thickness. Filler compound helps by:

- Reducing deformation in films and molded parts.

- Improving consistency, leading to less off-grade production.

In some cases, producers have reported scrap reductions of 5–10%, which translates into substantial savings over time, particularly in high-volume operations like packaging.

4. Economic Benefits for Manufacturers

4.1. Cost Per Kilogram Reduction

The most straightforward benefit of filler compound is the reduced cost per kilogram of finished plastic.

Let’s take a film extrusion example:

- Producing 1 ton of PP film with 100% virgin resin costs about $1,200.

- Producing 1 ton of PP film with 70% virgin resin + 30% CaCO₃ filler compound reduces the average cost to $960/ton.

That’s a 20% saving per ton — a figure that becomes monumental for manufacturers producing thousands of tons annually.

4.2. Scalability for Mass Production

The larger the production scale, the greater the financial impact. Packaging companies producing films for agriculture or FMCG, for example, can save hundreds of thousands of dollars annually through consistent use of filler compound.

In regions like Southeast Asia and the Middle East, where packaging demand is booming, filler compound has become a default strategy for maintaining margins without sacrificing competitiveness.

Why Filler Compound is Considered Cost-Saving?

4.3. ROI Perspective

Return on investment (ROI) from filler compound is immediate. Unlike expensive machinery upgrades or process automation, adopting filler compound requires no capital investment. Once manufacturers begin blending it into production, cost savings per kilogram are realized instantly.

5. Environmental and Sustainability Advantages

Cost savings are not the only reason filler compounds are gaining traction. They also align with sustainability goals, an increasingly important requirement for both regulators and end consumers.

5.1. Lower Carbon Footprint

By replacing part of virgin resin with mineral fillers, manufacturers consume fewer fossil-fuel-derived plastics. According to a 2023 European Plastics Association study, a 30% CaCO₃ filler compound blend can reduce CO₂ emissions by up to 20% per ton of plastic produced.

5.2. Supporting Circular Economy

Recycled plastics often suffer from inconsistent mechanical properties. Adding filler compound enhances stiffness and stability, making recycled content more usable in high-performance applications. This supports a circular economy, where materials remain in use longer and waste is minimized.

5.3. Reduced Plastic Waste

Improved durability means fewer breakages and replacements, lowering overall waste. For instance, filler-reinforced films used in agriculture last longer under UV exposure, reducing replacement frequency and material disposal.

Environmental and Sustainability Advantages of Filler Compound

6. Future of Filler Compounds in the Plastics Industry

The future of filler compound is shaped by cost, sustainability, and innovation.

-

Emerging markets: Demand is growing rapidly in Africa, Asia, and Latin America, where cost efficiency is a priority.

-

Nano-fillers: Research into nano-CaCO₃ and other advanced fillers is opening opportunities for even stronger, lighter, and more efficient compounds.

-

Global resin price volatility: As crude oil markets remain unpredictable, filler compounds will serve as a stabilizing cost factor for manufacturers.

7. Conclusion

Filler compound is more than just a way to cut expenses — it’s a strategic tool for cost optimization, efficiency, and sustainability in the plastics industry. By reducing virgin resin consumption, improving production efficiency, lowering scrap, and enabling greener practices, filler compounds help manufacturers remain competitive in a demanding global market.

For companies facing rising raw material prices and sustainability pressures, adopting filler compound is no longer optional — it’s a necessity.

8. FAQs About Filler Compound

Q1: Is filler compound the same as masterbatch?

No. Masterbatch is a concentrated form requiring dilution, while filler compound is a ready-to-use blend of resin and filler.

Q2: How much filler compound can I use?

It depends on the application. In films, up to 30–40% loading is common, while in injection molding, loadings are often 10–20%.

Q3: Does filler compound reduce product quality?

Not necessarily. When properly formulated, it can enhance stiffness and durability. However, excessive use without proper compatibilizers may reduce flexibility or transparency.

Q4: Is filler compound environmentally friendly?

Yes. By reducing virgin plastic use and supporting recycled resin performance, filler compounds help lower carbon emissions and support sustainability goals.

9. About EuroPlas

EuroPlas is one of the world’s leading suppliers of filler masterbatch, and additives, serving thousands of customers across 90+ countries. With advanced R&D, state-of-the-art manufacturing, and strict quality control, EuroPlas provides tailor-made filler masterbatches that deliver both cost savings and performance stability.

Whether you produce films, injection-molded goods, or high-demand industrial plastics, EuroPlas offers solutions designed to help you reduce resin costs, improve efficiency, and achieve sustainability targets.

📩 Contact EuroPlas today to explore how our filler masterbatches can optimize your production and drive long-term profitability.