The global packaging sector is undergoing rapid transformation. Rising raw material prices, stricter sustainability policies, and consumer expectations for high-quality yet affordable products are forcing companies to rethink how they design and manufacture packaging. One material solution stands out in this changing landscape: filler granules. More and more brands, from small regional players to multinational giants, are adopting filler granules to cut costs, optimize performance, and move closer to their sustainability goals. But what exactly are filler granules, how do they work, and why are they proving so popular in packaging? Let’s explore in depth.

1. Introduction to Filler Granules

Packaging has always been about balance: keeping costs low, ensuring functionality, and meeting sustainability targets. Today, that balance is more challenging than ever.

- Material costs are volatile. Polypropylene (PP) and polyethylene (PE) prices have fluctuated by over 30% in recent years (ResearchGate, 2024).

- Regulations are stricter. The EU Packaging Waste Directive requires all packaging to be recyclable or reusable by 2030 (EU Commission, 2024).

- Consumers expect better. A McKinsey survey in 2023 found that 60% of shoppers prefer products with sustainable packaging (McKinsey, 2023).

Filler granules—polymer blended with fillers such as calcium carbonate (CaCO₃) or talc—address these challenges. They reduce reliance on expensive virgin resin, cut costs, improve processing, and help brands align with sustainability commitments.

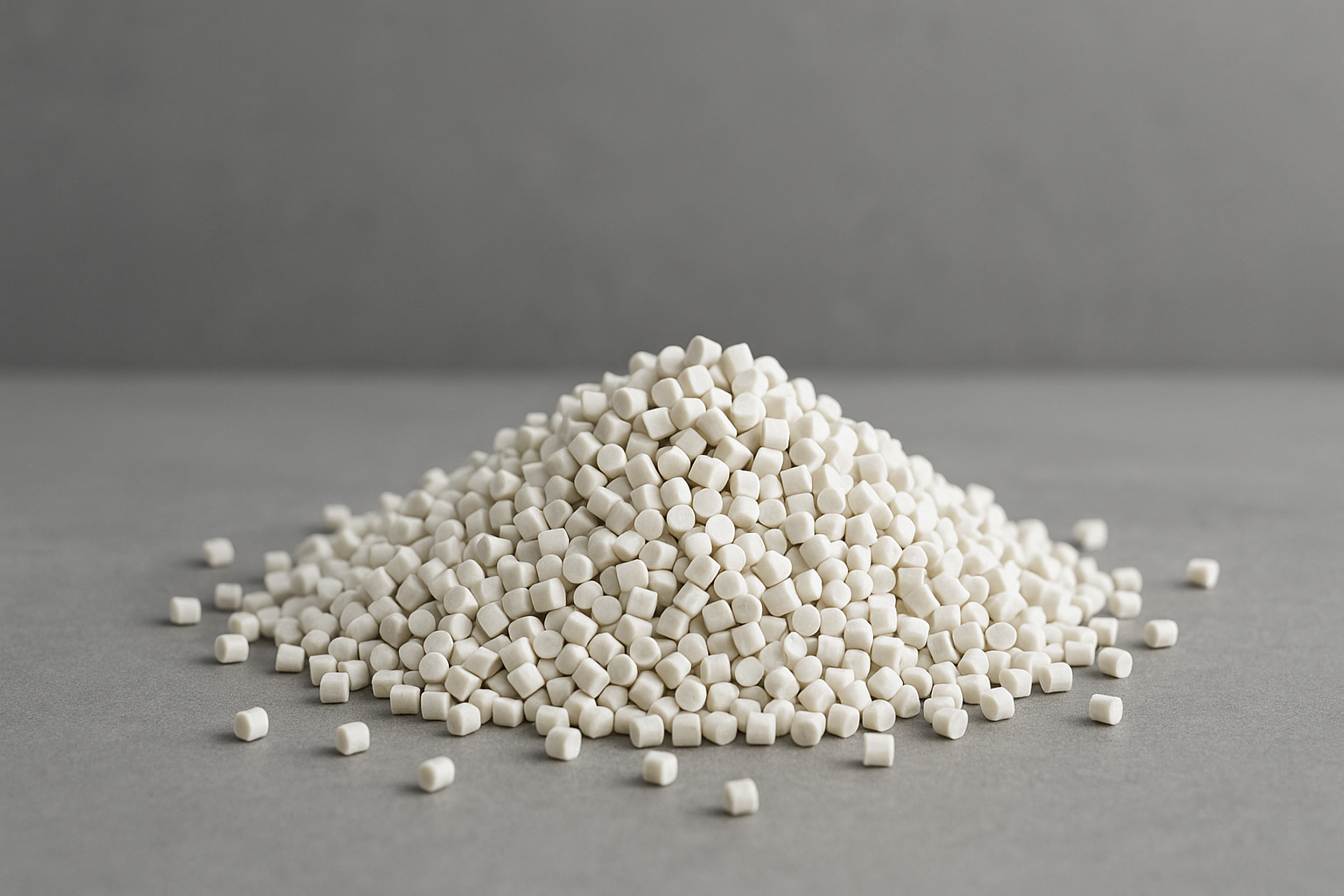

2. What Are Filler Granules?

2.1. Composition and Process

Filler granules are pre-compounded plastic pellets produced by combining:

- Resin (PE, PP, PS) as the base polymer.

- Mineral fillers like CaCO₃, talc, or barium sulfate.

- Compatibilizers/additives to ensure smooth dispersion.

They are created through melt-compounding and pelletizing, resulting in a ready-to-use product that goes straight into extrusion, blow molding, or injection molding.

Read more: Calpet, filler masterbatch, taical: what exactly they are?

What Are Filler Granules?

2.2. Types for Packaging Applications

Different packaging applications require different grades:

- Film grades – for bags, liners, and wraps.

- Rigid grades – for caps, containers, and trays.

- Specialty grades – with anti-static, anti-blocking, or optical properties.

This customization makes filler granules highly versatile across both consumer and industrial packaging.

3. Applications of Filler Granules in Packaging

3.1. Flexible Packaging

Flexible packaging accounts for 40% of the global market [Smithers, 2023]. Filler granules are widely used in:

- Shopping bags and garbage liners – where cost savings are critical.

- Agricultural films – where filler improves tear resistance.

- Food films – where opacity and printability are enhanced.

For instance, a Vietnamese packaging firm reported saving nearly 20% in raw material costs by introducing CaCO₃-based filler granules into grocery bag production.

3.2. Rigid Packaging

Rigid packaging demands strength and appearance. Filler granules add value in:

- Caps and closures – requiring precise fit and stability.

- Food containers – needing stackability without deformation.

- Cosmetic jars – benefiting from opacity and a premium surface look.

In these cases, filler granules help balance both performance and aesthetics.

3.3. Industrial and Agricultural Packaging

Heavy-duty packaging also benefits:

- Woven sacks for fertilizers or grain.

- Bulk bags (FIBCs) for transporting powders.

- Tarpaulins and sheets used in agriculture.

Here, filler granules allow competitive pricing without compromising durability—vital in cost-sensitive markets.

Applications of Filler Granules in Packaging

4. Why Are Brands Choosing Filler Granules?

The popularity of filler granules comes from a combination of economic, technical, and environmental benefits.

4.1. Cost Savings

Raw resin often represents 60–70% of packaging costs. Substituting part of it with lower-cost filler granules cuts expenses significantly.

- Example: 1 ton of PE film with virgin resin costs $1,200.

- Using 30% filler granules ($600/ton) lowers the average cost to about $960/ton.

That’s a 20% saving per ton, translating into millions for large-scale producers.

4.2. Enhanced Performance

Far from diluting quality, filler granules improve certain properties:

- Stiffness – essential for containers and sacks.

- Opacity – enhances branding and print visibility.

- Thermal conductivity – reduces cooling time during molding.

This means brands achieve both lower costs and improved packaging value.

4.3. Operational Efficiency

Processing is also smoother with filler granules:

- Better dispersion – fewer streaks or gels in films.

- Lower energy use – improved melt flow cuts electricity needs.

- Faster cycle times – enhanced heat transfer reduces production time.

The European Plastics Converters Association (EuPC) reported energy savings of up to 15% in film extrusion when CaCO₃ filler was used [EuPC, 2023].

4.4. Sustainability

Sustainability is another strong motivator:

- Reduced virgin plastic – less fossil fuel consumption.

- Lower emissions – a 2022 European Plastics Association report found a 20% CO₂ reduction per ton when 30% filler replaced resin.

- Improved recyclability – filler granules strengthen recycled plastic, enabling higher recycled content.

Why Are Brands Choosing Filler Granules?

5. Quantifying the Cost Advantage

Numbers often tell the most convincing story. When comparing filler granules to virgin resin, the savings are substantial and scalable.

5.1. Example Calculation: Virgin Resin vs. Filler Granule Blend

| Material |

Cost per ton |

Blend ratio |

Effective cost contribution |

| Virgin PE resin |

$1,200 |

70% |

$840 |

| Filler granules (CaCO₃-based) |

$600 |

30% |

$180 |

| Total cost per ton |

– |

100% |

$1,020 |

Result: Cost saving of $180 per ton (~15%) compared to using only virgin resin.

5.2. Cost Savings per Ton and Scalability

For a medium-sized packaging producer manufacturing 10,000 tons per year, even a 15% cost reduction translates into:

- $180 × 10,000 = $1.8 million in annual savings.

For large multinational packaging companies producing hundreds of thousands of tons, the impact is several times greater.

5.3. ROI Considerations

Unlike expensive machinery upgrades, filler granules require no new capital investment. ROI is immediate: savings begin from the first production batch. For smaller brands, this quick turnaround can be the difference between staying competitive or losing ground.

6. Environmental and Regulatory Benefits

Beyond economics, filler granules support companies in addressing regulatory demands and sustainability targets. Replacing a portion of virgin plastic with mineral filler means less reliance on fossil fuel–derived polymers, which directly lowers a company’s carbon footprint. The European Plastics Association has reported that a 30% substitution rate can reduce greenhouse gas emissions by up to 20% per ton of packaging produced.

This reduction matters because regulations around the world are tightening. The European Union has set a 2030 goal for all packaging to be recyclable or reusable, while countries like India have introduced strict rules banning certain single-use plastics. Extended Producer Responsibility schemes, already common in Europe and spreading globally, shift the financial burden of waste management to the brands placing packaging on the market. By reducing virgin resin usage through filler granules, brands show regulators and consumers alike that they are serious about compliance and environmental stewardship.

There is also a practical dimension: recycled plastics often struggle with inconsistent quality. Adding filler granules helps stabilize recycled resins, improving stiffness and dimensional stability, which allows a higher percentage of recycled content to be included without compromising performance. This makes it easier for packaging producers to integrate recycled materials and move closer to circular economy goals.

Beyond economics, filler granules support companies in addressing regulatory demands and sustainability targets.

7. Key Considerations When Using Filler Granules

Despite the advantages, filler granules are not a magic bullet. To reap the benefits without quality trade-offs, careful consideration is required.

One of the most important aspects is the loading ratio. In film applications, manufacturers often use between 20% and 40% filler granules, while in rigid packaging the proportion is usually lower, around 10% to 20%. Exceeding these levels without proper formulation can result in products that are too brittle or lack impact resistance.

Another consideration is balancing cost savings with specific product requirements. Food and medical packaging, for example, must adhere to stringent safety standards, which means only food-grade filler granules should be used. Premium consumer goods packaging may demand higher clarity or a more refined surface finish, requiring specially tailored grades.

Ultimately, choosing the right supplier is critical. Reliable partners provide not just the material, but also technical guidance on optimal ratios, machine settings, and performance testing. Without this expertise, brands risk undermining the very benefits they hope to achieve.

8. Future Trends in Filler Granules for Packaging

Looking ahead, filler granules are set to play an even bigger role in the packaging industry. Growth in emerging markets such as Southeast Asia, Africa, and Latin America is accelerating demand for cost-effective packaging. In these regions, margins are slim and affordability is key, making filler granules a natural choice.

Technological innovation is another driver. Researchers are developing nano-scale fillers such as nano-calcium carbonate, which promise to deliver not only cost savings but also improved barrier properties, lightweighting potential, and even functional enhancements like antimicrobial surfaces. These advancements could expand filler granules from being primarily a cost-control measure to becoming a tool for product differentiation.

At the same time, filler granules are being integrated with bioplastics and compostable resins. As the packaging industry explores alternatives to conventional plastics, the compatibility of fillers with bio-based materials will shape the next generation of sustainable packaging solutions. Allied Market Research predicts that the filler granules market in packaging will grow at a compound annual rate of 5.5% through 2030, reflecting these converging economic and sustainability trends.

Future Trends in Filler Granules for Packaging

9. Frequently Asked Questions

Are filler granules safe for food packaging?

Yes. Food-grade filler granules that comply with FDA and EU regulations are widely available and already used in films, containers, and closures for food applications.

Do filler granules reduce packaging quality?

Not if they are properly formulated and used in recommended proportions. In fact, they often enhance stiffness, opacity, and processability. Problems typically occur only when fillers are overused without adequate compatibilizers.

How much can a brand save by switching to filler granules?

Savings usually range between 15% and 30% per ton, depending on resin prices and blend ratios. For large producers, this can translate into millions in annual cost reductions.

What is the difference between filler granules and recycled resin?

Recycled resin is reprocessed plastic waste, while filler granules are a blend of virgin polymer and minerals. The two complement each other: filler granules can enhance the performance of recycled resins, making them easier to incorporate at higher percentages.

10. Conclusion

Filler granules have moved beyond being seen as a simple cost-cutting tool. They now represent a strategic solution for brands navigating the complex challenges of the modern packaging industry. By lowering material expenses, improving production efficiency, enhancing mechanical performance, and enabling more sustainable practices, filler granules offer value across the entire supply chain.

For companies facing volatile resin prices, regulatory pressure, and consumer scrutiny, adopting filler granules is not just a smart financial decision—it is increasingly a necessity. They provide a pathway to maintain competitiveness while aligning with the environmental expectations shaping tomorrow’s packaging landscape.

11. About EuroPlas

EuroPlas is a global leader in the development and supply of many products that supporting plastic manufacturing, including filler masterbatch. With customers in over 95 countries and the annual production capacity of 0.6 million tonnes/year, EuroPlas delivers tailored solutions that help packaging manufacturers cut costs, streamline production, and meet sustainability targets.

Our R&D teams continuously innovate to provide filler granules that work across a wide range of applications—from films and bags to rigid containers and industrial packaging. By combining advanced production facilities with strict quality control, EuroPlas ensures every shipment delivers consistent performance and maximum value.

📩 Contact EuroPlas today to explore how our filler granules can reduce your production costs and accelerate your path to sustainable packaging.