In the competitive world of plastic manufacturing, every step of the process is under scrutiny — and rightly so. From raw materials to machinery performance, small decisions can have big consequences. One such decision is how you use filler additive.

Filler additives are widely used in polymer production to reduce cost, modify material properties, and improve processing behavior. When used correctly, they can increase output and profitability. However, misuse or lack of technical understanding can lead to defects, downtime, or worse — product failure.

Whether you're a seasoned process engineer or new to polymer compounding, understanding the common mistakes when using filler additive can save you time, money, and frustration. In this guide, we’ll explore the most frequent pitfalls and offer practical solutions to ensure your filler additive works for you, not against you.

1. What Is a Filler Additive and Why It Matters

Filler additives are materials incorporated into a polymer matrix to enhance or modify its properties. Unlike reinforcing agents like fiberglass, fillers are primarily used to:

- Reduce production cost by replacing a portion of expensive resin

- Improve stiffness, opacity, and dimensional stability

- Enhance thermal conductivity and processability

Common examples include calcium carbonate (CaCO₃), talc, and barium sulfate. These mineral-based fillers are often compounded with carrier resins like PP or PE to form masterbatches, which are then blended with virgin resin at different ratios depending on the application.

Used correctly, a filler additive can be a powerful tool. But used poorly, it can lead to inconsistent quality, machine problems, and wasted material.

Filler additives are materials incorporated into a polymer matrix to enhance or modify its properties.

2. Common Mistakes and How to Avoid Them

Let’s take a closer look at the most common errors when using filler additives — and how you can sidestep them with a few smart practices.

2.1. Using the Wrong Filler for the Base Resin

The Mistake:

One of the most overlooked problems is a mismatch between the filler additive's carrier resin and the base resin being used. For example, using a PE-based filler with PP resin can lead to poor bonding and dispersion.

Consequences:

-

Weak interfacial adhesion

- Uneven flow in injection molding

- Surface defects like splay marks or weld lines

Solution:

Always match the carrier resin of your filler additive with your main polymer. If you're working with PP, choose a PP-based filler. Consult the product datasheet or your supplier to confirm compatibility before proceeding.

2.2. Overloading the Filler Additive

The Mistake:

It's tempting to push filler loading as high as possible to cut material costs. But too much filler can backfire.

Consequences:

-

Brittleness and reduced impact strength

- Warping and poor dimensional accuracy

- Shorter tool life due to increased abrasion

What’s “Too Much”?

For most mineral fillers like calcium carbonate, the recommended dosage ranges from 5% to 40%. Going beyond this range may reduce part performance unless the formulation is specially engineered.

Solution:

-

Stick to supplier-recommended filler ratios

- Begin testing at low filler levels (10–20%)

- Adjust gradually while monitoring mechanical and visual properties

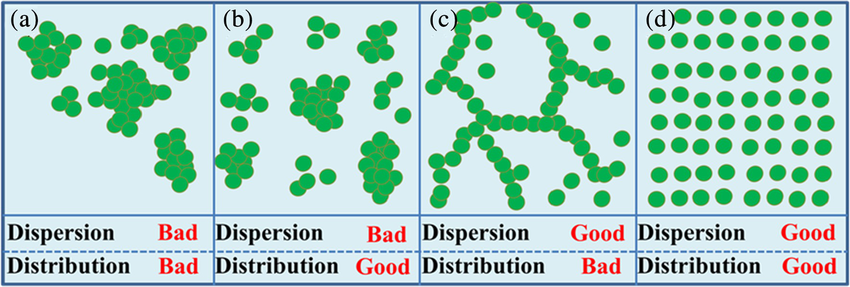

2.3. Poor Dispersion Within the Polymer Matrix

The Mistake:

Even the best filler won’t work if it’s not evenly dispersed. Poor dispersion often stems from inadequate mixing equipment or poor-quality masterbatch.

Signs of Poor Dispersion:

-

White streaks, speckling, or color inconsistencies

- Variability in part weight or wall thickness

- Clogged molds or extrusion dies

Why It Happens:

-

Using low-shear mixing systems

- Skipping drying steps for hygroscopic fillers

- Relying on filler with high moisture content or agglomerates

Even the best filler won’t work if it’s not evenly dispersed.

Solutions:

-

Use high-shear mixers or twin-screw extruders

- Choose high-dispersion filler masterbatch with fine particle size

- Store filler additive in dry, sealed containers with desiccants

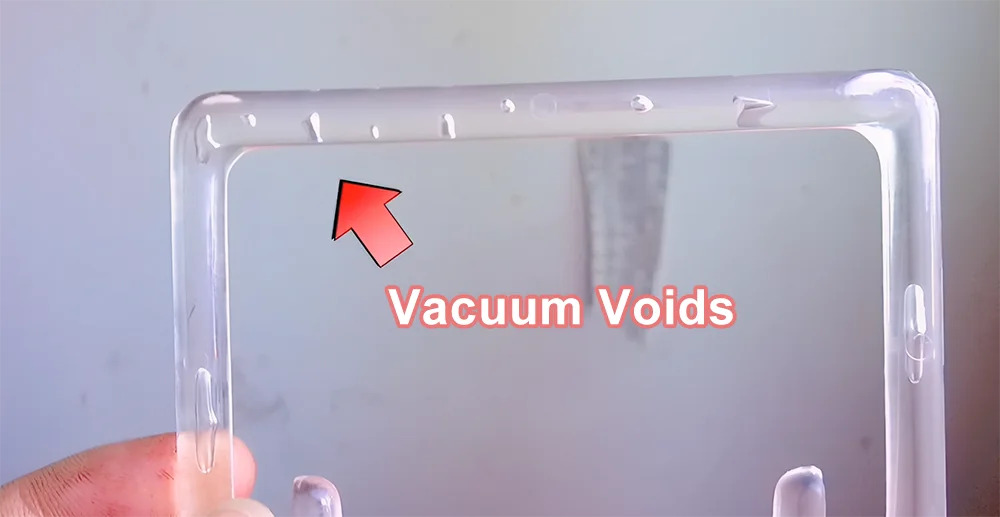

2.4. Ignoring Moisture Content in Filler Additive

The Mistake:

Moisture is the silent killer in polymer processing — especially when working with mineral fillers.

Consequences of Moisture:

-

Bubbles and voids in molded parts

- Blistering or foaming during extrusion

- Weakened bonding and surface blemishes

Why It Happens:

-

Filler bags left open in humid environments

- No pre-drying before feeding into hopper

- Filler stored without moisture control

How to Avoid It:

-

Pre-dry filler at 80–100°C for 2–4 hours if needed

- Store filler in sealed packaging

- Use desiccant or drying hoppers for large-scale operations

- Monitor ambient humidity in storage areas

Pro Tip:

If your filler bag feels cool to the touch, it's likely absorbed moisture. Dry it before use — even if the supplier says it's “ready-to-use.”

Moisture is the silent killer in polymer processing — especially when working with mineral fillers.

2.5. Inconsistent Quality Between Batches

The Mistake:

Switching filler suppliers too often or sourcing low-grade material can lead to batch-to-batch inconsistencies in your final product.

Possible Effects:

-

Fluctuations in melt flow rate (MFI)

- Differences in color or surface appearance

- Unexpected shrinkage or dimensional variation

- Difficulty maintaining consistent machine settings

Why It Matters:

Production lines thrive on stability. Even slight changes in filler particle size, dispersion quality, or moisture level can disrupt settings, causing waste and downtime.

How to Avoid:

-

Partner with reliable, ISO-certified filler additive manufacturers

- Request Certificates of Analysis (COA) with each batch

- Run quick tests on incoming raw materials: moisture, MFI, visual dispersion

- Avoid frequent supplier switching unless technically justified

2.6. Using Non-Compliant Fillers for Regulated Applications

The Mistake:

Overlooking regulatory requirements when choosing filler additives can result in compliance violations, product recalls, or even legal consequences.

Risk Scenarios:

-

Using non-food-grade filler for packaging in direct contact with food

- Failing to ensure UV-resistance for outdoor applications

- Ignoring RoHS or REACH compliance for electronic components

Solution:

-

Always match filler properties with end-use requirements

- For food-contact applications: ensure fillers are FDA, EU, or China GB certified

- For outdoor use: request UV-stabilized filler masterbatch

- For electronics: verify compliance with RoHS, REACH, and halogen-free regulations

3. Summary Table: Common Mistakes and How to Avoid Them

| Mistake |

Impact |

Solution |

| Wrong filler-resin match |

Weak bonding, surface defects |

Match carrier resin to base resin |

| Overloading filler |

Brittleness, warping, high reject rate |

Stay within 5–40% depending on part design |

| Poor dispersion |

Inconsistent properties, visual defects |

Use high-dispersion filler, mix well |

| Moisture in filler |

Bubbles, foaming, cracks |

Pre-dry, seal storage, use desiccant |

| Batch inconsistencies |

MFI fluctuation, process instability |

Choose consistent, certified suppliers |

| Misaligned filler vs. application |

Compliance failure, premature degradation |

Use application-specific, certified filler |

4. Expert Tips for Success with Filler Additive

4.1. Collaborate With Your Supplier

Your filler additive supplier isn’t just a vendor — they should be your technical partner.

-

Share your application, base resin, and processing conditions

- Ask for customized recommendations

- Request small-scale trial batches to validate formulations

4.2. Validate Performance in Lab and Production

Before committing to full-scale production:

-

Run MFI, tensile strength, and impact testing

- Check surface appearance, shrinkage, and dimensional tolerance

- Evaluate performance at different filler loadings (e.g., 10%, 20%, 30%)

5. Conclusion

Filler additives are not just cost-cutting tools — when used properly, they become performance enhancers. But the line between optimization and overuse is thin.

Many issues like poor surface finish, cracking, or inconsistent quality trace back to simple mistakes:

-

Choosing the wrong filler for your resin

- Overloading beyond recommended ratios

- Neglecting proper mixing, drying, and storage

By understanding these common pitfalls and following best practices, manufacturers can unlock the full potential of filler additives — achieving better product quality, higher output, and lower total cost.

6. About EuroPlas: Your Trusted Filler Masterbatch Partner

EuroPlas, a brand under EuP Group, is one of the world’s top producers of filler masterbatch, headquartered in Vietnam. With over 15 years of expertise and an annual capacity of 0.8 million tonnes/year, EuroPlas exports to more than 95 countries, supporting global manufacturers in packaging, injection molding, film blowing, extrusion, and more.

EuroPlas offers a comprehensive range of Calcium Carbonate Masterbatch products:

If you are interesting in our products, please don't hesitate to contact us for more information!

EuroPlas offers a comprehensive range of Calcium Carbonate Masterbatch products

7. Frequently Asked Questions (FAQ)

7.1. What is the ideal filler loading percentage?

Most applications work well between 5–40%, depending on target cost, strength, and processing conditions.

7.2. Can filler additives be used in recycled plastic?

Yes. In fact, CaCO₃ filler often improves processing and consistency in recycled materials.

7.3. Do fillers affect recyclability?

No — mineral fillers like calcium carbonate are generally recyclable and compatible with most recycling processes.

7.4. Is it safe to use filler in food-contact packaging?

Only with certified food-grade filler masterbatches that meet FDA or EU standards.

7.5. Can one filler work for both PE and PP?

Not recommended. Always use a filler with a carrier resin that matches your base polymer for optimal performance.