Potato bioplastic, a sustainable material made from potato starch, is increasingly gaining attention in the agricultural sector. As concerns over plastic waste and soil health continue to rise, this biodegradable alternative offers a promising path toward greener farming practices. But how exactly is potato bioplastic made? And what role can it play in agriculture? Let’s explore the potential and process behind this eco-friendly innovation.

1. Understanding Potato Bioplastic

1.1. What is Potato Bioplastic?

Potato bioplastic is a type of biodegradable plastic derived from the starch of potatoes. Unlike traditional plastics made from petroleum, it is fully compostable and breaks down naturally under suitable environmental conditions. Classified as a starch-based biopolymer, it is part of a growing class of bio-based materials that offer similar utility to plastic without long-term environmental damage.

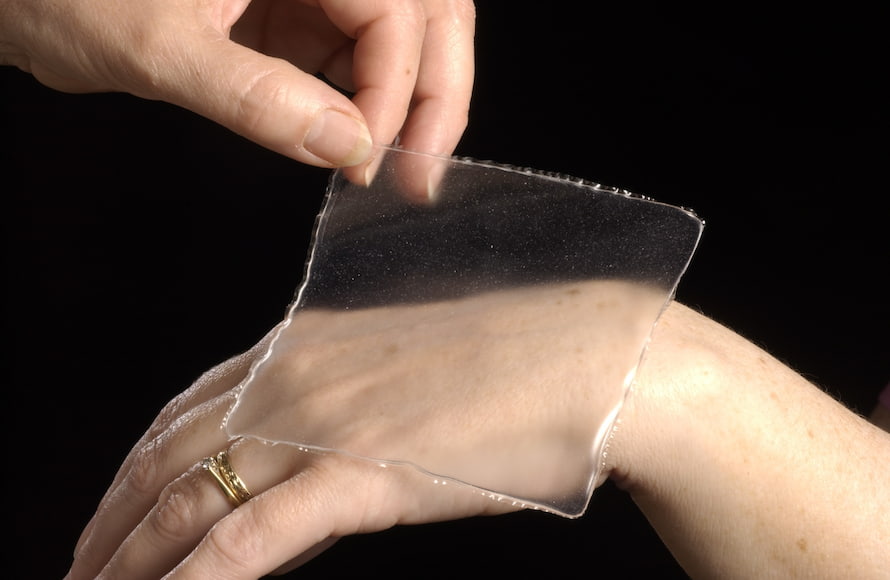

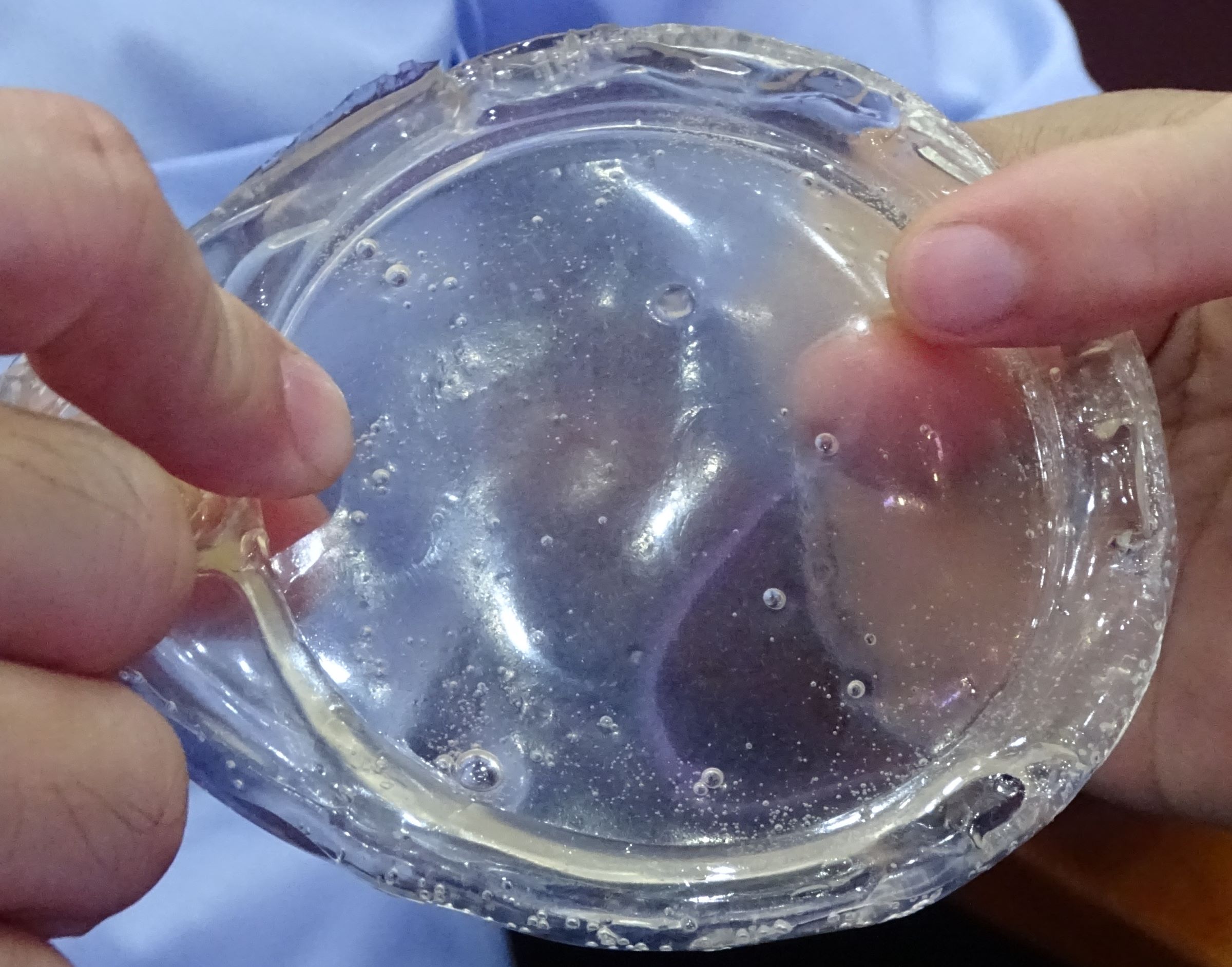

This form of bioplastic is flexible, lightweight, and suitable for forming films, containers, trays, and packaging – making it a useful alternative in both commercial and agricultural settings. It is especially attractive for short-life applications such as mulch films or seedling trays that benefit from natural decomposition after use.

1.2. How is It Made?

Potato bioplastic can be made using a relatively straightforward process, which makes it accessible not just to industrial manufacturers but also for educational and small-scale demonstration purposes. Here's a step-by-step overview of how it's produced:

- Starch Extraction: Potatoes are peeled, chopped, and blended with water to release the starch.

- Filtration and Settling: The mixture is filtered and left to settle, allowing starch to separate.

- Plasticizing: The extracted starch is then mixed with plasticizers like glycerol and water, sometimes with vinegar or citric acid to improve elasticity.

- Heating: The mixture is heated and stirred to initiate gelatinization and bonding.

- Casting and Drying: The solution is poured onto a flat surface or mold and left to dry at low temperatures, forming a thin, flexible plastic sheet.

💡 Educational example: Many schools demonstrate this process in science projects to show how bioplastics work in practice. The simplicity of the method helps promote awareness of sustainable materials.

.jpg)

Understanding Potato Bioplastic

1.3. Is It Truly Biodegradable?

Yes, potato bioplastic is biodegradable under the right environmental conditions. It typically decomposes within 90–180 days in composting environments. Unlike fossil-fuel plastics, it doesn’t leave behind microplastics or toxic residues.

However, the rate of decomposition depends on:

- Temperature

- Humidity

- Soil microbial activity

In agricultural settings, when used as mulch film or planting containers, potato bioplastic will naturally break down in soil after fulfilling its functional purpose.

2. Why Potato Bioplastic Is a Sustainable Choice in Agriculture

2.1. Reducing Plastic Pollution in Fields

Plastic pollution from conventional mulch films and seedling trays has become a growing concern in agriculture. Traditional polyethylene-based films may take hundreds of years to degrade, leaving behind plastic fragments that affect soil quality and crop health.

Potato bioplastic addresses this issue directly:

- It degrades naturally, reducing waste accumulation.

- No toxic residues or microplastics remain in the soil.

- Farmers don’t need to remove used films after harvest, saving labor and disposal costs.

According to a study by the University of Wageningen, biodegradable mulch films can reduce plastic residue in soil by over 80% within a single growing season.

2.2. Lowering Carbon Footprint

Unlike petroleum-based plastic production, which generates significant greenhouse gas emissions, potato bioplastic has a much lower carbon footprint. Here's why:

- The raw material – potato starch – is renewable and abundant.

- Some manufacturers use food waste or non-edible potatoes, adding circular value.

- Processing temperatures are lower, saving energy during production.

By switching to starch-based bioplastics, the agricultural sector can significantly reduce its environmental impact without compromising on performance.

2.3. Supporting Soil Health

When plastic breaks down into microplastics, it can interfere with soil microbial activity and water retention. Over time, this degrades soil quality, affecting crop productivity.

Potato bioplastic offers a more soil-friendly alternative:

- It enriches microbial biodiversity as it decomposes.

- It avoids chemical leaching.

- It supports regenerative agricultural practices by promoting healthier soil structures.

Read more: Potato Starch Bioplastic: Pros and Cons You Should Know

Why Potato Bioplastic Is a Sustainable Choice in Agriculture

3. Key Applications in Agriculture

3.1. Mulch Films

One of the most impactful uses of potato bioplastic in agriculture is in biodegradable mulch films. These films are spread across fields to suppress weed growth, regulate soil temperature, and retain moisture.

Advantages include:

- Eliminates the need for post-harvest film collection

- Breaks down naturally into the soil

- Reduces labor and waste disposal costs

- Maintains crop yield comparable to traditional films

Farmers cultivating crops like tomatoes, cucumbers, and strawberries have reported successful adoption of these films with added soil health benefits.

3.2. Seedling Pots and Trays

Traditional plastic seedling trays often get discarded after a single use. Biodegradable pots made from potato bioplastic offer a smart solution.

- Transplant directly into the soil — no root disturbance

- Break down within weeks, enriching the soil

- Ideal for nurseries, home gardens, and sustainable farms

This innovation helps eliminate plastic waste in the early stages of plant growth and simplifies logistics for small and medium growers.

3.3. Agricultural Packaging and Labeling

Potato bioplastic is also being used to replace plastic in fertilizer bags, seed pouches, and crop labels.

- Lightweight and durable for short-term storage

- Compostable packaging aligns with eco-certifications

- Branding opportunities for “green” producers

Brands that adopt bioplastic packaging are also more attractive to environmentally conscious consumers, giving them a competitive edge.

3.4. Controlled-Release Fertilizer Capsules

Another innovative use is in encapsulating fertilizers or pesticides with thin potato bioplastic coatings. This enables controlled-release systems that:

- Improve efficiency of nutrient uptake

- Minimize runoff into water bodies

- Reduce the frequency of application

These capsules dissolve gradually, aligning fertilizer delivery with crop needs while reducing environmental impact.

4. Limitations and Challenges

While the benefits are clear, potato bioplastic also faces several challenges in broader agricultural use.

4.1. Cost Competitiveness

Compared to traditional plastics, potato bioplastic remains more expensive due to:

- Smaller production scale

- Higher cost of raw material processing

- Limited economies of scale

However, as demand increases and production scales up, these costs are expected to decrease over time.

4.2. Durability and Water Sensitivity

Potato-based materials tend to:

- Be less mechanically strong than fossil-based plastics

- Soften when exposed to high humidity or water

Solutions being explored:

- Blending with other biopolymers like PLA or PHA

- Applying biodegradable coatings to improve strength

4.3. Market Awareness and Adoption

- Many farmers are unaware of this alternative

- Some remain skeptical of its reliability

- Supply chains for bioplastic mulch or trays are still developing in many countries

Greater outreach, education, and demonstration projects are key to promoting adoption.

5. The Future of Potato Bioplastic in Agriculture

5.1. Material Science Innovation

Research is ongoing into improving starch-based plastics. Future developments may include:

- Nanotechnology-enhanced strength and moisture resistance

- Blending with other plant-based inputs like corn or cellulose

- Smart degradation systems that adjust based on field conditions

5.2. Policy Support

Governments around the world are:

- Phasing out single-use fossil plastics

- Offering subsidies or tax incentives for biodegradable alternatives

- Supporting public procurement of green materials

Such policies can accelerate adoption in public sector agriculture and rural development programs.

5.3. Integration into Circular Agriculture

Potato bioplastic fits perfectly within a circular farming economy:

- Use of surplus or reject-grade potatoes

- Films and trays that return to the soil

- Closing the loop between waste and productivity

As sustainability becomes a central theme in agriculture, materials like potato bioplastic will play a bigger role.

The Future of Potato Bioplastic in Agriculture

6. Conclusion

Potato bioplastic is more than just an experiment in green innovation — it is a practical and scalable solution to reduce plastic waste, support healthy soil, and future-proof farming. From mulch films to seedling trays and packaging, its uses in agriculture are growing steadily.

While challenges around cost and performance remain, ongoing innovation and awareness campaigns are bridging the gap. With the right support, this humble starch-based plastic could be one of agriculture’s most eco-friendly allies in the years ahead.