The demand for biodegradable polymers is an important development trend related to the environment. Today, consumers tend to be interested in industrial development, CO2 emissions, and fossil fuel conservation. Some of the world's big brands like Walmart are shifting their use of plastic from petroleum to biodegradable plastic. The trend towards biodegradable polymers is benefiting from the narrowing of the price gap between petroleum-based polymers and biodegradable polymers over the past few years.

Biodegradable polymers have been studied for more than a decade, however, new products have been introduced commercially within the last 5-7 years. Biodegradable polymers are preferred for use in a number of areas such as food packaging, bags and sacks, agricultural mulch, and other applications. The major suppliers that are entering the market include NatureWorks LLC, Novamont, and BASF.

You may be interested in:

- What is Biodegradable Packaging? Biodegradable Packaging Advantages and Disadvantages

- Create a bioplastic business plan in 4 steps

- What are bioplastics made from? Materials to make bioplastics

1. Biodegradable polymer - what is it?

According to ASTM, biodegradable plastic is a degradable plastic in which degradation results from the action of natural microorganisms such as bacteria, fungi, and algae.

Standardizing organizations such as CEN, International Organization for Standardization (ISO) and American Standards (ASTM), the European standard EN 13432 encourages the development of standard tests so that this biodegradation can is determined. There is a growing worldwide need for standards for assessing the suitability of polymeric materials for the treatment of specific wastes in the anaerobic or disintegrating plastic stream.

2. Mechanism of biodegradable polymer

Biodegradation is generally defined as degradation caused by biological activity, which will often occur concurrently with, and sometimes is initiated by, non-biological degradation such as photosynthesis and hydrolysis.

Many different polymers can be hydrolyzed, and different mechanisms of hydrolysis are present in most media.

Biological degradation takes place through the action of enzymes or by-products (such as acids and peroxides) secreted by microorganisms (bacteria, yeasts). In addition, microorganisms can ingest, and sometimes digest polymers, and some are caused by mechanical, chemical, and enzymic aging.

3. Method for determination of biodegradation

Due to the different mechanisms of biodegradation of polymers, biodegradation depends not only on polymer chemistry, but also on the presence of biological systems involved in the process. When studying the biodegradation of materials, the influence of the environment is a factor that cannot be ignored. Bacterial activity and biodegradation are influenced by:

- Microorganisms

- Availability of oxygen

- Amount of water available

- Temperature

- Environmental chemicals (pH, electricity, etc.)

Four commonly available approaches to the study of biodegradation processes are used.

- Monitor the growth of bacteria

- Monitor background deterioration

- Product reaction monitoring

- Monitor changes in background properties

4. Factors affecting biodegradation

There are three factors that affect biodegradation:

- The environment is an important factor affecting the rate and degree of biodegradation of polymer substrates.

- Polymer chemistry regulates the physical and chemical properties of a material and its interaction with the environment, thereby influencing the decay of the material with specific degradation mechanisms.

- The accessibility of the polymer to enzymes is extremely important because the first step in plastic degradation often involves the actions of extracellular enzymes.

5. Types of biodegradable polymers

There are three types of commercially available biodegradable polymers:

- Undenatured polymers derived from nature are susceptible to bacterial-enzyme attack.

- Synthetic polymers, mainly polyester.

- Natural biodegradable polymer modified with additives and fillers.

6. Several biodegradable polymers on the market

6.1. Naturally Biodegradable Polymers

Naturally biodegradable polymers are produced in nature by all living organisms. Biodegradation reactions are usually catalyzed by enzymes and occur in an aqueous solution. Natural molecules containing hydrolyzable bonds, such as proteins, cellulose, and starches, are generally susceptible to biodegradation by microbial hydrolytic enzymes. Therefore, the hydrophobic/hydrophilic character of polymers greatly influences their biodegradation. It also has a big impact on performance and durability in wet conditions.

Polysaccharides like starch are the most common in nature. Fatty polyesters such as polyhydroxyalkanoates (PHAs) are also a line of naturally occurring biodegradable polymers that are beginning to have commercial applications.

6.2. Synthetic Biodegradable Polymers

While naturally biodegradable polymers are produced by living organisms, synthetic biodegradable polymers are produced only by humans.

The main types of synthetic biodegradable polymers include aliphatic polyesters with a hydrolyzable bond along the polymer chain such as polylactic acid (PLA).

6.3. Modified Naturally Biodegradable Polymers

Over the years, much effort has been made to improve synthetic biodegradable polymers by incorporating polysaccharide-derived materials.

The most prominent natural biodegradable polymer material used commercially is manufactured by Novamont under the trade name Mater-Bi. This technology is based on the main raw material of starch. Novamont manufactures several different types of Mater-Bi, all of which contain starches with different synthetic ingredients such as Polycaprolactone (PCL). The material obtained is suitable for film and sheet production, and injection molding.

6.4. Starch-Based Biodegradable Polymers

In nature, in addition to the available starch, the second type is cellulose. The most important industrial sources are corn starch, wheat, potatoes, tapioca, and rice.

Starch is completely biodegradable in many environments and thus allows the development of fully biodegradable products for specific market needs. The degradation or incineration of re-starch products during the recycling process does not cause global warming.

Polyhydroxyalkanoates

Polyhydroxyalkonates (PHA) is a term in the family of aliphatic polyesters produced by biodegradable microorganisms. They provide a wide range of physical properties of plastics from hard and brittle to elastic.

Applications of PHA

– Packaged food

- Houseware

– Household electrical and electronic equipment

– Agricultural mulch film

– Some medical products (bone plates and surgical sutures)

6.5. Polylactic Acid Polyesters

Polylactic acid (PLA) is a biodegradable polymer derived from lactic acid. It is a versatile material and is made from 100% renewable resources such as corn, sugar beet, wheat, and other starchrich products. Polylactic acid has many features that are equivalent to or better than many petroleum-based plastics, which make it suitable for many applications.

This material has lower tensile strength, higher elongation, and a much faster degradation time. PLA is about 37% crystalline, with a melting point of 175-178°C and a glass transition temperature of 60-65°C. process.

PLA also compares with petrochemical plastics based on the application for packaging. It's clear and shiny like polystyrene, it's resistant to moisture and grease, and it has the same odor-blocking properties as polyethylene terephthalate (PET). The tensile strength and elongation, the elasticity of PLA are also compared with that of PET.

6.6. Polycaprolactone (PCL)

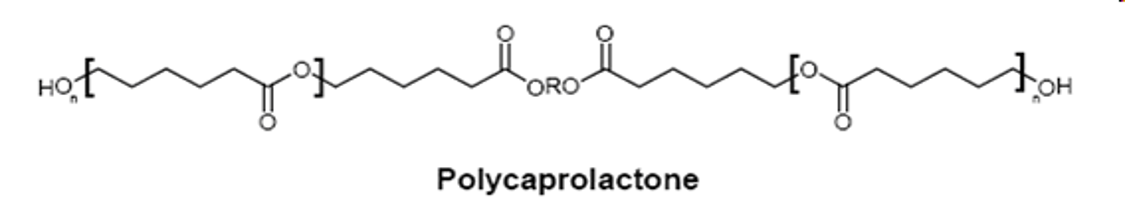

Cyclic polymers ε-caprolactone is a semi-crystalline polymer with a melting point of 59-64°C and a glass transition temperature of -60°C. This polymer has high compatibility and was originally used. in the medical field as a biodegradable sewing material in Europe.

Benefits when blends with renewables:

- Moisture resistance and durability in blends with starch and thermoplastic starch (TPS)

- Enhanced flexibility and impact strength in blends with polylactides (PLA)

- Processing aid and improvement of mechanical properties together with polyhydroxyalkanoates (PHA/PHB)

Benefits in blends with fossil-based:

- Processing aid that favors biodegradation

- Food contact approved

Examples of Use:

- Main component

- Additive

- Blends with other bioplastics

- Suitable for fridge and freezer applications

- Film applications for food

- Electronic equipment – mobile handsets, casings

- Automotive parts

- Disposables – plastic bags, compost bags, one-time use items

- Agricultural films, pots, and plant clips

- Reusables – cutlery, trays