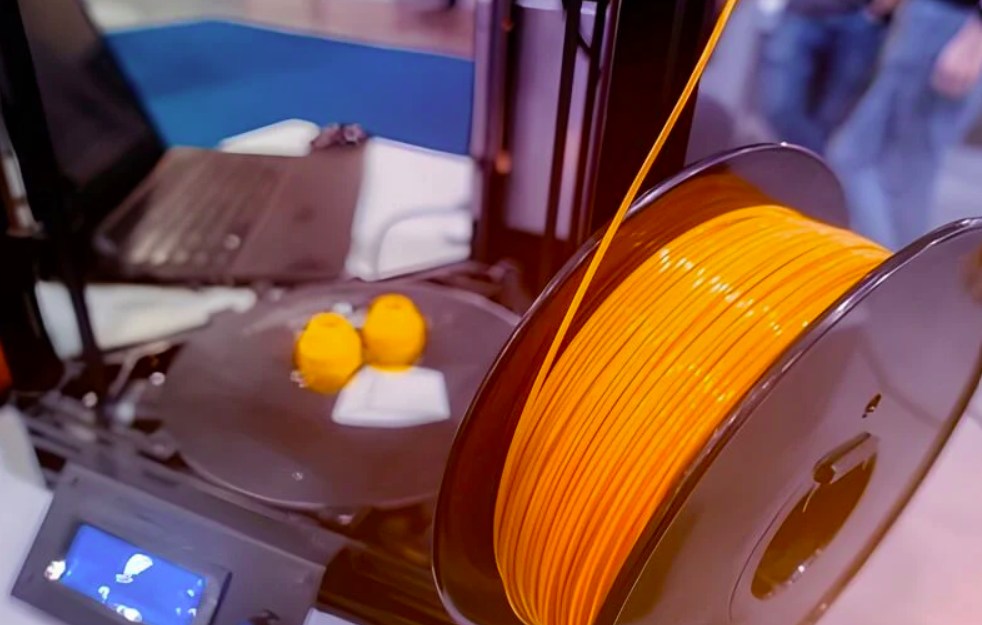

In 3D printing, ABS (Acrylonitrile Butadiene Styrene) filament is a popular choice due to its durability and impact resistance. However, achieving high-quality ABS prints relies heavily on using the correct ABS temperature settings. This article provides a comprehensive guide to understanding the ideal ABS temperature range, addresses common printing issues related to temperature, and offers practical tips for optimizing your ABS printing process.

1. What is the Ideal ABS Temperature?

ABS, or Acrylonitrile Butadiene Styrene, is a durable thermoplastic widely used in various industries, including automotive and consumer goods, due to its strength, flexibility, and ability to withstand high impact. When printing with ABS filament in 3D printing, one critical factor influencing the print's success is achieving the correct ABS temperature settings. Unlike other filaments like PLA, ABS requires higher ABS temperature levels for successful adhesion, layer bonding, and minimal warping.

Understanding the Ideal ABS Temperature Ranges

The key ABS temperature settings to focus on are the extruder temperature, the heated bed temperature, and the ambient temperature. Each plays a crucial role in achieving a high-quality print with minimal defects.

- Extruder Temperature: Typically, the ideal ABS temperature for the extruder is between 230-250°C. Setting the extruder within this range ensures that the filament melts consistently, allowing each printed layer to bond firmly with the next. Generally, for most types of ABS, 235°C is effective, but it may vary depending on the brand and environmental factors. Ensuring the extruder remains within this range is essential for strong inter-layer bonding, as temperatures below 230°C often result in poor adhesion, while temperatures above 250°C can lead to overheating, causing stringing or excessive oozing.

- Bed Temperature: To reduce warping and improve bed adhesion, ABS requires a heated bed set between 90-110°C. The right ABS temperature for the bed keeps the printed layers warm, preventing rapid cooling and contraction, which can cause warping. Warping is one of the most common issues when printing with ABS, as it causes the edges of the print to lift off the bed. Ensuring the bed temperature is within this ideal ABS temperature range stabilizes the layers and provides a smooth, consistent print base.

- Ambient Temperature and Enclosure: ABS filament is sensitive to changes in ambient temperature. Maintaining a stable ABS temperature environment around the print is crucial to minimize warping and prevent cracks in the print layers. For this reason, using an enclosure for the 3D printer can help maintain a warm, controlled environment, avoiding sudden temperature fluctuations that could affect the print quality. Enclosures also help with keeping fumes contained, as ABS produces noticeable fumes during printing.

By adjusting these three primary ABS temperature parameters, you can significantly improve the quality and durability of ABS prints, ensuring each layer bonds properly and that the print remains stable throughout the process.

Read more: ABS Antistatic compound

ABS Glass fiber compound

ABS flame retardant compound

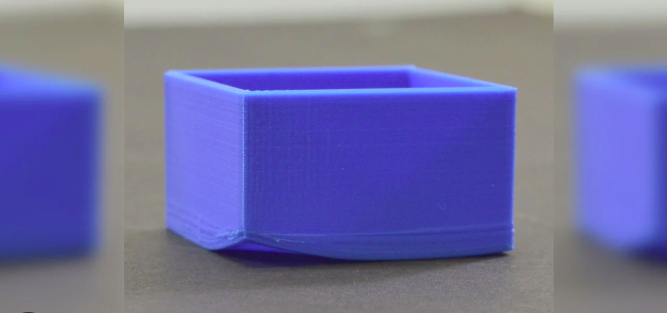

ABS plastic requires higher ABS temperature to ensure good adhesion and minimize deformation

2. Temperature Settings and Common ABS Printing Issues

While ABS is a strong and versatile material, incorrect ABS temperature settings often lead to common printing issues. Understanding these issues and the role that ABS temperature plays in causing them is essential for troubleshooting and achieving high-quality results.

2.1. Warping and Bed Adhesion

Warping is perhaps the most frequent issue when printing with ABS. It occurs when the material cools too quickly or unevenly, causing the bottom layers to contract and pull away from the print bed. This phenomenon is highly temperature-sensitive and often arises due to improper ABS temperature settings for the bed or the surrounding environment.

- Preventing Warping through Bed Temperature Control: Setting the print bed to an appropriate ABS temperature (90-110°C) is the first step in addressing warping. A heated bed minimizes rapid cooling, allowing the printed layers to settle without lifting. Additionally, applying adhesives such as glue sticks or ABS slurry can enhance bed adhesion at this ABS temperature range.

- Using an Enclosure for Stability: Enclosures help keep the ambient temperature stable, preventing rapid cooling that could lead to warping. Since ABS is particularly sensitive to environmental changes, an enclosure that keeps the ABS temperature stable around the print is essential for preventing temperature-related issues.

ABS 3D printing plastic

2.2. Layer Separation and Poor Interlayer Bonding

Layer separation or poor bonding between layers usually occurs when the ABS temperature for the extruder is too low. ABS layers need to be warm enough to fuse correctly, and when the extruder temperature falls below 230°C, the layers may cool before bonding fully.

Ensuring Strong Bonding with Optimal Extruder Temperature: To prevent layer separation, the extruder should be set to an ABS temperature above 230°C. For most ABS prints, setting the extruder to 235-245°C can provide adequate bonding strength. If layer separation still occurs, adjusting the ABS temperature by 5-10°C can make a significant difference in layer adhesion.

Adjust ABS temperature to improve adhesion of layers

2.3. Overheating and Stringing

Overheating and stringing occur when the extruder ABS temperature is set too high, causing the filament to melt excessively. This leads to issues such as thin strings or fine strands between different parts of the print.

Avoiding Stringing with Controlled Extruder Temperature: Lowering the extruder ABS temperature slightly or enabling retraction settings can help reduce stringing. It’s essential to find a balance where the filament melts smoothly without overheating or oozing excessively.

The ABS extruder temperature must be moderate to avoid overheating and filamentation

2.4. Reducing Shrinkage and Warping

Shrinkage and deformation often occur due to sudden cooling, as ABS contracts when it cools. By maintaining a stable ABS temperature environment, especially through the use of an enclosure, you can significantly reduce these issues.

3. Practical Tips for Achieving Optimal ABS Print Quality

In addition to setting the correct ABS temperature, several techniques and tools can help improve print quality and reduce common issues like warping and layer separation. By combining these methods with proper ABS temperature settings, you can achieve stronger, more consistent ABS prints that meet high-quality standards.

3.1. Testing for Optimal ABS Temperature with Calibration Tools

ABS filament can vary in its ideal temperature range based on the manufacturer, environmental factors, and specific filament properties. To find the most effective ABS temperature settings, running a calibration test, such as printing a temperature tower, is highly recommended. A temperature tower is a specially designed 3D model with incremental temperature changes along its height, allowing you to observe how the filament performs at different temperatures within a single print. This tool enables you to identify the ABS temperature that provides the best balance of layer adhesion, surface smoothness, and structural strength.

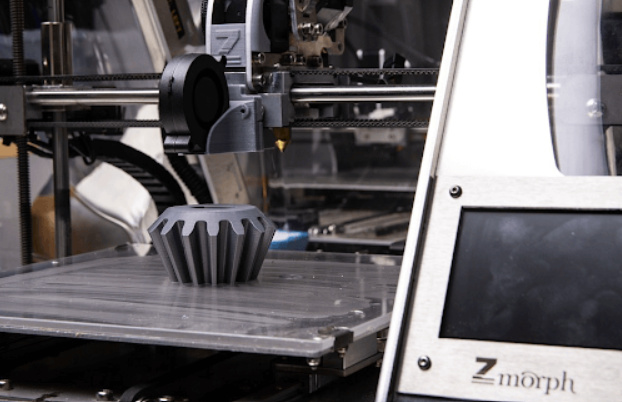

ABS 3D printers should be equipped with additional covers to prevent sudden temperature changes

3.2. Enhancing Bed Adhesion with Surface Preparation

ABS is prone to warping and detaching from the print bed as it cools, particularly at its edges. Preparing the print bed is essential to improve bed adhesion, which is the foundation of a stable print. Here are some effective techniques for enhancing adhesion:

- Adhesives: Applying adhesives like glue sticks, hairspray, or a homemade ABS slurry (ABS filament dissolved in acetone) on the print bed provides a sticky surface, preventing the first layers from lifting as they cool. When applied on a heated bed set between 90-110°C, these adhesives create an optimal environment for ABS prints.

- Special Bed Surfaces: Upgrading the print bed surface with materials like glass or PEI (Polyetherimide) sheets improves adhesion even further. Glass beds provide a smooth, flat surface, while PEI sheets can enhance grip, especially under higher bed temperatures, reducing the risk of warping.

- Textured Beds: Some users opt for textured surfaces, which can increase adhesion by creating more contact points between the filament and the bed. Combined with the correct ABS temperature settings, textured beds can improve print stability, especially for larger or complex parts.

3.3. Controlling the Ambient Temperature with Enclosures

Maintaining a stable ambient temperature is crucial for ABS printing, as sudden temperature fluctuations can cause uneven cooling, warping, or even cracking. Using an enclosure around the 3D printer is one of the most effective ways to control the ambient temperature around the print, especially if you are working in a drafty or unregulated space.

- Maintaining Temperature Stability: An enclosure helps retain the heat generated by the heated bed and extruder, creating a warm, stable environment that minimizes the risk of warping. This is especially important for larger ABS prints, where different areas of the print may cool at different rates without a controlled environment.

- Reducing Warping and Cracking: The enclosure helps keep layers warm during the printing process, which is essential for ABS, as rapid cooling can lead to layer separation or shrinkage. With a stable ambient temperature, the print cools more gradually, resulting in stronger layer bonding and minimizing cracks.

Managing Fumes: ABS emits fumes while printing, which may be irritating or unsafe in unventilated spaces. An enclosure can help contain and direct these fumes, making it easier to manage them with a vent or filtration system.

ABS plastic is commonly used in personal or professional 3D printers

3.4. Optimizing Retraction Settings to Minimize Stringing and Oozing

Stringing and oozing—when thin, unwanted strands of filament appear between different parts of the print—are common issues if the extruder ABS temperature is too high or retraction settings are not optimized. Here’s how you can address these challenges:

- Fine-Tune Retraction Distance and Speed: Retraction settings determine how much filament is pulled back before the print head moves. Setting the retraction distance and speed correctly reduces the amount of molten filament that may ooze out between print moves. Start with small adjustments, as too high retraction values can lead to under-extrusion, while too low settings may cause more stringing.

- Adjust Extruder Temperature: If stringing persists, slightly lowering the extruder ABS temperature can help reduce the filament’s fluidity, thereby minimizing oozing. Avoid setting the temperature too low, as this could lead to poor layer adhesion.

3.5. Managing Print Speed for ABS Prints

ABS printing generally benefits from a moderate print speed, balancing precision with efficient print times. Here’s how print speed affects ABS quality:

- Preventing Warping and Deformation: Slower print speeds can reduce warping by allowing each layer more time to cool and settle before the next layer is applied. This is particularly useful for larger prints, where rapid changes in temperature could otherwise cause distortion.

- Improving Layer Bonding: Slower speeds also give the extruder more time to maintain consistent filament flow, helping each layer bond securely to the one below. This reduces the likelihood of layer separation, enhancing the strength and durability of the finished print.

3.6. Regular Maintenance for Reliable ABS Printing

Regular maintenance of your 3D printer ensures that the ABS temperature settings and other parameters remain consistent across multiple prints:

- Nozzle Cleaning: ABS has a tendency to clog nozzles if it burns or cools too quickly. Routine cleaning of the nozzle reduces the risk of clogs and maintains consistent extrusion.

- Bed Leveling: An uneven bed can lead to inconsistent first layers, impacting bed adhesion. Regularly leveling the bed or investing in an auto-leveling system helps ensure a stable base for each print.

- Calibrating Temperature Sensors: Over time, temperature sensors may lose accuracy, leading to fluctuations in actual extruder or bed temperatures. Regular calibration helps ensure that the ABS temperature settings you input are accurately reflected in the print.

By following these tips and continuously fine-tuning your ABS temperature and printer settings, you can achieve exceptional print quality with ABS filament, avoiding common pitfalls and enhancing your overall 3D printing experience. These adjustments can make a significant difference in creating durable, precise, and aesthetically pleasing ABS prints.

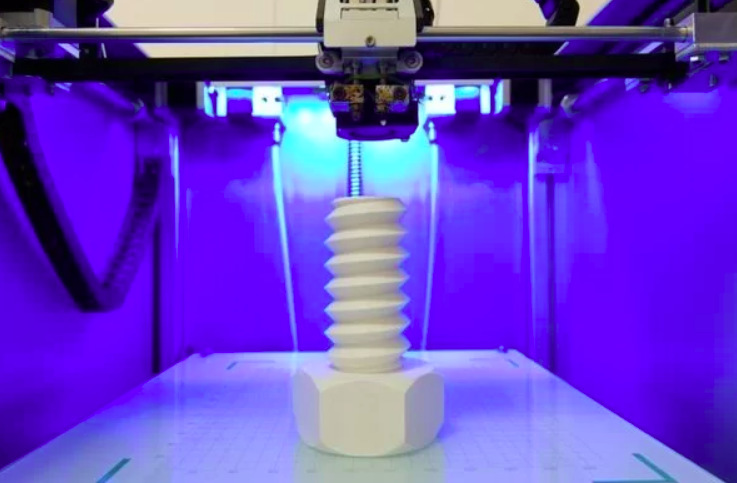

Tips for achieving optimal ABS print quality

4. Conclusion

To achieve optimal print quality with ABS filament, mastering ABS temperature settings for the extruder, bed, and surrounding environment is essential. Typical ABS temperature ranges for successful printing are 230-250°C for the extruder and 90-110°C for the bed, though these may vary depending on factors like filament type, printer model, and ambient conditions.

Maintaining a stable environment, using an enclosure, adjusting print speed, and enhancing adhesion can help prevent issues like warping and layer separation. Each type of ABS may need unique ABS temperature adjustments, so testing is necessary to determine the ideal range. Regular printer maintenance is also crucial to ensure smooth operation and extend the printer's lifespan.

With proper ABS temperature optimization, ABS provides excellent strength and durability, making it ideal for applications requiring rigidity.

ABS temperature setting is the key to successful 3D printing

5. About EuroPlas

EuroPlas is a leader in providing high-quality ABS, PLA, and other advanced polymer solutions tailored to meet the diverse needs of industries and individual users alike. Our dedication to innovation and quality has established us as a trusted name in the plastics field. Through a comprehensive product lineup—including Filler Masterbatch, Color Masterbatch, Plastic Additives, Engineering Plastics Compounds, Bioplastic Compounds, and Bio Filler —EuroPlas empowers manufacturers to enhance their operations, lower manufacturing costs, and improve material properties.

In particular, our expertise in ABS and temperature-specific requirements helps ensure optimal performance in 3D printing and other applications. Using the right ABS temperature settings is crucial for print adhesion, durability, and minimizing warping. By incorporating advanced automation and high-performance materials, we enable businesses to achieve precision and efficiency while strengthening their competitive edge in an ever-evolving market.

Contact us today to learn more about the ideal ABS temperature and best practices, and visit our blog to explore industry-focused topics that can help you enhance production capabilities with advanced plastic solutions from EuroPlas.