In an era where sustainability is no longer optional but a necessity, Flexible Intermediate Bulk Containers (FIBC bags) have emerged as a game-changing solution. Their role in modern packaging goes beyond mere functionality, contributing to eco-friendly practices across industries. To truly appreciate their impact, it’s essential to understand the sustainability features that make FIBC bags a preferred choice for businesses worldwide.

1. Sustainability Features of FIBC Bags

FIBC bags, also known as bulk bags or jumbo bags, are specifically designed to align with sustainable packaging goals. Their production and usage offer numerous ecological benefits that make them a preferred choice in modern supply chains. Below are some of the most notable features:

- Reusable and durable: One of the most defining attributes of FIBC bags is their reusability. Unlike single-use packaging materials, FIBC bags can withstand multiple cycles of use when handled correctly. Their durability allows them to carry heavy loads without the risk of tearing or breaking, making them ideal for long-term use in various industries. This durability is particularly beneficial for companies looking to reduce costs associated with frequent packaging replacements and ensure reliability in demanding environments.

- Recyclable materials: The majority of FIBC bags are made from polypropylene (PP), a type of plastic that can be recycled into other products such as furniture, car parts, and even new FIBC bags. This recyclability reduces the amount of waste sent to landfills, significantly lowering the environmental footprint. When businesses prioritize the proper recycling of FIBC bags, they contribute to a circular economy, promoting sustainable resource management and extending the life cycle of materials.

- Lightweight yet strong: Despite their robust capacity, FIBC bags are lightweight, which not only facilitates easier handling but also reduces the energy required for transportation. By decreasing fuel consumption, businesses can cut down on greenhouse gas emissions during shipping. Furthermore, their compact design when empty allows for efficient storage and transport, further optimizing logistics and reducing operational costs for industries.

- Customization for efficiency: FIBC bags can be customized to specific sizes and designs based on the needs of the product they will carry. This minimizes excess material usage and helps optimize storage and logistics, reducing waste in the supply chain. Custom features such as spouts, liners, and lifting loops enhance their usability across diverse applications, from food-grade storage to hazardous material transport.

- Lower carbon footprint: The entire lifecycle of an FIBC bag, from production to recycling, is more eco-friendly compared to many other types of packaging. Companies using these bags often report a noticeable reduction in their overall carbon footprint. By incorporating advanced production technologies and renewable energy sources, manufacturers are further improving the environmental performance of FIBC bags. For instance, utilizing solar power in production facilities or sourcing recycled polypropylene can significantly enhance the green credentials of these bags.

FIBC bags have many outstanding features to become the top choice

Read more: Types of FIBC bags and their manufacturing process

2. Applications in Sustainable Supply Chains

FIBC bags have become an essential tool for industries looking to improve their sustainability practices. Their versatility and efficiency allow them to integrate seamlessly into various sectors, contributing to greener supply chains.

- Agriculture sector: FIBC bags are widely used for storing and transporting agricultural products such as grains, seeds, and fertilizers. Their ability to carry large volumes with minimal packaging materials makes them a cost-effective and eco-friendly choice. Additionally, their robust design ensures that agricultural products are protected from contamination and wastage during transit. By reducing product loss and spoilage, FIBC bags help farmers and distributors achieve greater sustainability, supporting global food security initiatives and minimizing the carbon footprint of agricultural logistics.

The bags ensure agricultural products are protected from contamination

- Construction industry: For construction materials like sand, gravel, and cement, FIBC bags provide an excellent solution. These bags can hold several tons of material at a time, reducing the need for smaller, single-use packaging. Moreover, their reusability aligns with the industry's increasing focus on reducing construction waste. By incorporating FIBC bags into projects, construction companies can streamline material handling while minimizing their environmental impact. In addition, their stackable design allows for efficient storage at construction sites, reducing space constraints and operational delays.

- Food and beverage industry: FIBC bags are often manufactured to meet food-grade standards, making them suitable for carrying bulk quantities of sugar, flour, and other food products. The use of these bags minimizes packaging waste while maintaining product safety and hygiene. Additionally, their moisture-resistant properties ensure the integrity of food items during storage and transportation, addressing key concerns in the food supply chain. By reducing reliance on disposable packaging, the food and beverage industry can align with consumer demands for sustainable practices and reduce overall environmental impact. (Source: Top Benefits of Using Food-Grade FIBC Bags for Your Company)

- Chemical industry: Handling and transporting chemicals require robust and secure packaging. FIBC bags are not only durable but can also be customized with anti-static or conductive properties to safely carry hazardous materials. Their reusability reduces the reliance on disposable containers in this sector. By adopting FIBC bags, chemical companies can enhance safety protocols while contributing to sustainability goals. Additionally, incorporating features like leak-proof liners ensures that these bags meet strict regulatory standards while protecting the environment from potential chemical spills.

- Waste management: FIBC bags are increasingly being used for collecting and transporting recyclable waste. Their large capacity and strength make them ideal for managing heavy or bulky waste materials, supporting circular economy initiatives. Municipalities and waste management companies can benefit from these bags' efficiency in handling and sorting waste, making recycling efforts more effective. The use of FIBC bags in construction and demolition waste management, for example, has proven to be a cost-effective solution for handling large debris volumes while ensuring compliance with environmental regulations.

FIBC bags can be applied in many industries

3. Challenges and Solutions

Despite their numerous benefits, FIBC bags face certain challenges that need to be addressed to maximize their contribution to sustainable packaging.

| Challenge |

Description |

Solution |

| Limited Recycling Infrastructure |

Although FIBC bags are recyclable, the availability of polypropylene recycling facilities is limited in many regions. Without proper infrastructure, these bags may still end up in landfills, negating their sustainability benefits. |

- Invest in expanding recycling facilities and educate users on proper disposal practices.

- Collaborate with recycling companies to improve the collection and processing of used FIBC bags.

- Introduce incentives for businesses that recycle their packaging materials. |

| Improper Handling and Maintenance |

Incorrect handling, overloading, or exposure to harsh conditions can reduce the lifespan of FIBC bags, leading to increased waste. |

- Provide training and guidelines for proper usage and maintenance to extend their usability.

- Incorporate clear labeling and instructions on the bags to promote better handling practices.

- Implement quality control measures during manufacturing to ensure that each bag meets the durability standards required for long-term use. |

| Initial Cost Barrier |

The upfront cost of FIBC bags may be higher than traditional packaging options, deterring smaller businesses from adopting them. |

- Raise awareness about the long-term cost savings and environmental benefits of FIBC bags.

- Offer financial incentives or subsidies for businesses transitioning to sustainable packaging.

- Industry associations can advocate for policies that support the adoption of eco-friendly packaging solutions.

Environmental Impact of Production |

| Environmental Impact of Production |

Although FIBC bags are eco-friendly during use, their production still involves energy-intensive processes. |

- Implement renewable energy sources and improve production efficiency to minimize the environmental impact of manufacturing.

- Research alternative raw materials and greener production technologies.

- Manufacturers can adopt closed-loop production systems that recycle waste materials generated during the manufacturing process. |

FIBC bags offer many benefits but also face many challenges

4. Conclusion

FIBC bags have proven to be a transformative solution for sustainable packaging. By integrating these bags into their supply chains, industries can significantly reduce their environmental footprint while improving operational efficiency. From their reusability and recyclability to their versatile applications across various sectors, FIBC bags offer a practical and eco-friendly alternative to traditional packaging materials.

However, to fully realize their potential, stakeholders must address the existing challenges, such as recycling infrastructure and initial costs. By fostering collaboration among manufacturers, governments, and end-users, FIBC bags can play a pivotal role in driving the global shift toward sustainable packaging practices. With continued innovation and commitment to environmental stewardship, these bags will remain at the forefront of eco-friendly industrial solutions. They symbolize a tangible step toward achieving a more sustainable future, balancing economic and environmental priorities effectively.

FIBC bags are sustainable, making them both economically and environmentally efficient

5. About EuroPlas

EuroPlas is a leading provider of high-quality polypropylene (PP) materials that serve as the foundation for manufacturing FIBC bags. Our commitment to innovation and sustainability has established us as a trusted name in the plastic industry. With a wide range of customizable, durable, and eco-friendly PP products, we empower manufacturers to create superior FIBC bags, enabling businesses to enhance their operations, reduce packaging waste, and improve supply chain efficiency.

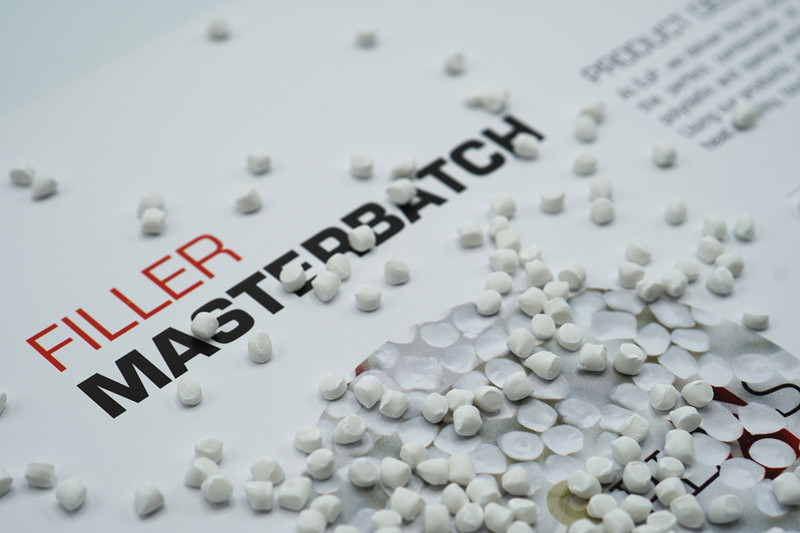

This product is a solution that helps PP textile manufacturers optimize costs and improve many properties of FIBC bags

Through our comprehensive product lineup—including Filler Masterbatch, Color Masterbatch, Plastic Additives, Engineering Plastics Compounds, Bioplastic Compounds, and Bio Filler —we empower businesses to enhance their operations, lower costs, and improve material properties.

Contact us today to learn more about our FIBC bags and other innovative solutions for sustainable packaging. Explore our blog for insights into industry best practices and discover how EuroPlas can help you optimize your production processes while prioritizing environmental stewardship.