PBT compound is a highly versatile material known for its exceptional properties. Its adaptability makes it suitable for a wide range of industrial applications, from automotive components to consumer electronics. This introduction delves into the extensive uses of PBT compound, highlighting its significant role in enhancing product performance across various sectors.

1. Overview Of PBT Compound

PBT compound is an engineering plastic derived from polybutylene terephthalate (PBT) resin, a versatile thermoplastic engineering polymer known for its exceptional mechanical properties and ease of processing. Exhibiting high tensile strength, thermal stability up to 150oC, and excellent resistance to chemicals, PBT is ideal for demanding applications. Its outstanding electrical insulation and low moisture absorption make it a preferred choice in the automotive, electrical, and electronics industries. Despite its brittleness at low temperatures and sensitivity to UV radiation, PBT can be enhanced with additives and reinforcements like glass fiber, flame retardants, and UV stabilizers. These modifications expand its applicability, ensuring reliable performance in various environments.

PBT compound is an engineering plastic derived from polybutylene terephthalate (PBT) resin

2. Applications Of PBT Compound To All Industries

PBT compound is a versatile engineering plastic with a wide range of applications across various industries. Its unique combination of properties, including strength, durability, heat resistance, and chemical resistance, makes it a preferred choice for numerous components and products.

2.1. Automotive Industry

PBT’s ability to withstand high temperatures, chemicals, and mechanical stress makes it ideal for various automotive components, following details:

- Under-the-hood components: The under-hood environment is harsh, with high temperatures, fluids, and vibrations. PBT’s heat resistance, chemical resistance, and dimensional stability make it an excellent choice for components in the engine compartment like intake manifolds, sensor housings, throttle bodies, fuel system components, insulation components like spark plug boots and ignition coil housings, etc.

- Interior and exterior components: PBT’s aesthetic appeal, combined with its durability, makes it suitable for interior components such as door handles, center console components, dashboard elements, housings for headlights and tail lights, etc.

PBT compound for automotive interior and exterior components

2.2. Electrical and Electronics

PBT compound is a preferred choice in the electrical and electronic industry due to its excellent electrical insulation, dimensional stability, and heat resistance.

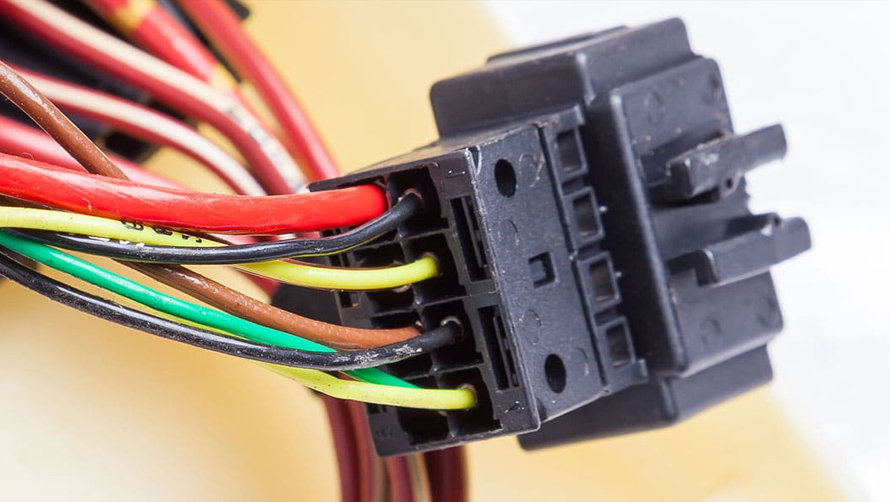

- Connectors and switches: Its excellent electrical insulation properties make PBT compounds particularly useful in applications such as wire-to-wire, wire-to-board, and board-to-board connectors, as well as switches, and sockets in various electronic devices, providing durability and consistent performance in demanding environments.

- Consumer electronics: It’s also used in consumer electronics such as housings and internal components of smartphones, laptops, and television devices. The material’s ability to provide a smooth surface finish and high impact resistance makes it ideal for protecting delicate electronic circuits.

PBT compound is a preferred choice in the electrical and electronic industry

2.3. Packaging

- Food packaging: Sometimes PBT compounds are used in food contact applications due to their safety and compliance with food safety standards. Its high thermal stability makes it ideal for packaging applications that require sterilization, such as ready-to-eat meals and dairy products. This ensures that the food remains safe and fresh throughout its shelf life.

- Industrial packaging: Utilized in containers and packaging materials that require strength and stability. It is used to manufacture heavy-duty containers and packaging materials that must withstand harsh handling and environmental conditions. Its resistance to chemicals and solvents is particularly beneficial in packaging applications for hazardous materials, ensuring that the packaging remains intact and effective in containing and protecting the contents.

PBT compound is utilized in industrial containers and packaging materials

2.4. Industrial Applications

- Machinery components: PBT compound is employed in the manufacturing of various machinery components, including gears, pulleys, bearings, and other mechanical parts that need strength, rigidity and wear resistance. These components benefit from PBT compound’s high tensile strength and excellent dimensional stability, ensuring reliable performance under mechanical stress and heavy loads. The material’s wear resistance enhances the longevity and efficiency of machinery parts, reducing maintenance and replacement costs.

- Industrial conveyor belts: Used for its durability and ability to withstand continuous stress and movement. Conveyor belts made from PBT compound exhibit high wear resistance and excellent dimensional stability, ensuring smooth and efficient operation even under constant use. The material’s low friction coefficient helps in reducing energy consumption and wear, prolonging the lifespan of the conveyor belts.

2.5. Medical Devices

PBT compound, while not as prevalent in medical applications as some other polymers, finds specific niches due to its unique properties.

- Surgical instruments: Occasionally used in non-implantable surgical instruments and devices due to its sterilization capabilities and chemical resistance. Surgical instruments such as forceps, clamps, and handles for surgical tools benefit from PBT compound’s ability to withstand repeated sterilization processes, including autoclaving, without degrading. Its resistance to various chemicals ensures that the instruments remain intact and functional when exposed to disinfectants and cleaning agents.

- Diagnostic equipment: Found in housings and internal components of diagnostic machines due to PBT compound’s robustness and thermal stability. The diagnostic machines include MRI machines, CT scanners, and blood analyzers that require materials that can endure the operational stresses and high temperatures associated with these devices. Its electrical insulation properties are also critical in ensuring the safety and reliability of diagnostic equipment, which often involves complex electronic systems.

PBT compound is used in conveyor belts that transport medical supplies, pharmaceuticals, etc.

2.6. Consumer Goods

PBT compound is an essential component in many household appliances. Its ability to withstand high temperatures and maintain its structural integrity makes it ideal for:

- Household appliances: Found in parts of appliances such as coffee makers, irons, and washing machines due to its heat resistance and durability.

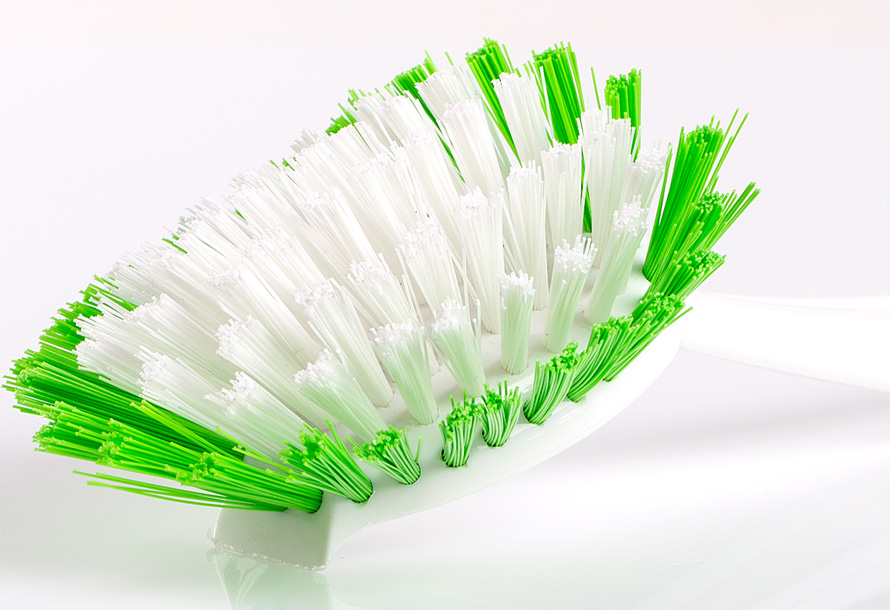

- Toothbrushes and False Eyelashes: PBT Compound is commonly used to make toothbrush bristles and false eyelashes due to its durability and abrasion resistance. In toothbrushes, PBT bristles are known for their flexibility and ability to maintain their shape even after extensive use. This ensures effective cleaning and long-lasting performance. Similarly, PBT is used in false eyelashes because it can replicate the natural look and feel of real eyelashes while being resistant to wear and tear.

PBT Compound is commonly used to make toothbrush bristles

2.7. Aerospace

- Interior components: Used in aircraft interiors for its lightweight, strength, and flame-retardant properties. In an industry where weight reduction is crucial for fuel efficiency and performance, PBT compound offers a perfect balance of strength and lightness. It is used to manufacture seat components, overhead bins, paneling, and other interior fixtures, providing the necessary durability and structural integrity while minimizing weight.

- Electrical system: PBT compound is applied in the electrical systems of aircraft, where high reliability and performance under varying conditions are critical. Components such as connectors, wire insulation, circuit breakers, and relay housings benefit from PBT compound’s excellent electrical insulation properties and thermal stability.

PBT compound is used to manufacture seat components, overhead bins, etc.

2.8. Renewable Energy

- Solar panels: The harsh outdoor environment demands materials with excellent durability and resistance to environmental factors. PBT compound fulfills these requirements, making it suitable for various components in solar panel systems, including: Junction boxes (protecting electrical components from moisture, dust, and extreme temperatures), frame components (providing structural support and resistance to corrosion), connector housings (ensuring reliable electrical connections and weatherproofing).

- Wind turbines: The demanding conditions of wind turbine operation require materials with high strength, durability, and resistance to fatigue. PBT compound, when reinforced with glass fibers or other additives, can be used in various wind turbine components like blade components, nacelle covers, electrical housing, and cable insulation. The material’s high impact resistance ensures that these components can withstand the mechanical stresses and vibrations associated with wind turbine operations. PBT compound’s excellent thermal stability and chemical resistance make it suitable for use in both onshore and offshore wind turbines, where exposure to harsh weather conditions and saltwater is common.

PBT compound’s high impact resistance can withstand the mechanical stresses and vibrations of wind turbine operations

2.9. Construction industry

PBT compounds are widely used in the construction industry due to their good mechanical strength, fire and heat resistance.

- Fireproof construction materials: Construction materials made from PB compound can withstand high temperatures and prevent the spread of flames, making them ideal for use in building components that require high safety standards. These materials are often used in fire-resistant panels, electrical enclosures, and structural elements where enhanced fire safety is critical.

- Water pipes: PB compound’s chemical resistance and durability make it highly suitable for water pipes and other water-related products in the construction industry. It can be used in various applications, such as domestic water supply pipes, industrial water pipes for wastewater treatment plants and industrial fluid conveyance, and agricultural irrigation systems.

PB compound’s chemical resistance and durability make it highly suitable for water pipes

2.10. Telecommunications

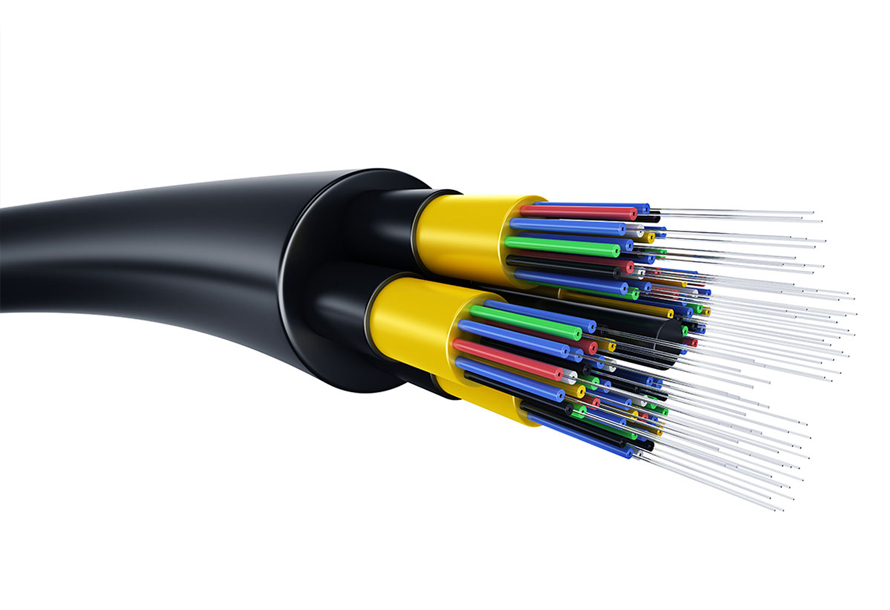

PBT compound is extensively used in the telecommunications industry, particularly in the production of fiber optic systems and parts of antennas.

- Fiber optic components: Used in housings and connectors for fiber optic systems due to its precision and stability.

- Antenna parts: Employed in parts of antennas and other communication equipment. Its strength, durability, and dimensionally make it suitable for antenna housings, connector housings and other antenna components.

PBT compound is used in housings and connectors for fiber optic systems

3. Why Is PBT Compound Commonly Used?

PBT compound is a popular choice for engineers and manufactures due to its exceptional combination of properties. Its inherent strength, rigidity, and toughness make its ideal for components subjected to mechanical stress. The material’s excellent heat resistance and dimensional stability ensure consistent performance in demanding environments.

Additionally, PBT is easily processed and can be modified with additives to tailor its properties for specific needs, further expanding its versatility and utility. PBT possesses good chemical resistance, making it suitable for applications involving exposure to various substances. These properties, coupled with its ease of processing and ability to be modified with additives, contribute to PBT’s widespread use across diverse industries.

4. Conclusion

PBT compound proves its worth as a versatile engineering plastic through its widespread applications. From enhancing automotive performance to power electronic devices, its contributions are undeniable. PBT compound enhances the durability and efficiency of countless products. Its versatility and reliability solidify its role as a key material in modern manufacturing, meeting the evolving needs of diverse industrial sectors.

5. About EuroPlas’ PBT Compound

EuroPlas’ PBT compound is a premium product designed to meet the rigorous demands of various industries. Our PBT compounds are built upon the strong foundation of polybutylene terephthalate (PBT) resin, known for its inherent strength, heat resistance, and dimensional stability.

However, EuroPlas takes it a step further. We strategically incorporate additives and reinforcements to enhance specific properties based on the intended applications. This meticulous approach allows EuroPlas’ PBT compound to possess superior properties.

EuroPlas elevates Polybutylene Terephthalate (PBT) to a whole new level with its premium

PBT GF-FR compound. Building upon the strong foundation of PBT’s inherent strength, heat resistance, and dimensional stability, EuroPlas strategically incorporates glass fibers (GF) and flame retardant (FR) additives. This meticulous approach tailors the material for applications demanding both high stiffness and excellent fire safety.

For more information on EuroPlas’ PBT compound options and how they can benefit your specific application, please contact us

here.