When it comes to manufacturing, choosing a suitable material is crucial. One of the most popular options in the market is black ABS plastic. This material has a variety of excellent qualities that make it a top choice for many products. This article will explore these qualities and why you should consider using black ABS plastic for your products.

What is black ABS plastic?

Black ABS plastic is a black thermoplastic polymer that combines three monomers - Acrylonitrile, Butadiene, and Styrene - to create a unique material. The combination of these three monomers is what makes ABS plastics so strong, rigid, and impact-resistant.

As a thermoplastic, ABS turns liquid at 105°C, which is also its glass transition temperature. They can be heated to their melting point, cooled, and re-heated without deterioration. This property enables them to be easily injection molded and then recycled.

Is black ABS plastic of good quality?

Black ABS plastic has become a popular choice in a wide range of industries due to its excellent combination of properties, including:

- Impact resistance: Black ABS plastic can withstand significant impact and force without cracking or breaking, making it a reliable material for long-lasting products.

- Structural strength and stiffness: ABS plastic is often used in structural applications thanks to its ability to handle heavy loads and maintain its shape under pressure.

- Chemical resistance: This material is also highly resistant to chemicals, making it an excellent material for applications that involve exposure to harsh chemicals.

- Excellent adaptability: ABS plastic performs exceptionally well in high and low temperatures. It can withstand temperatures ranging from -40°C to 80°C.

- Electrical insulation: This thermoplastic has excellent insulation and resistance to electricity. This makes it an ideal material for products that protect electrical components.

- High customizability: ABS is easy to paint and glue. Products made from this material will easily be customized to the requirements.

Moreover, black ABS plastic is a cost-effective material compared to other plastics. It is a readily available material and can be easily sourced from suppliers. Its lower cost also makes it an excellent choice for products that need to be produced in large quantities, such as consumer goods and packaging.

Common applications of black ABS plastic

Black ABS plastic, in particular, is widely used in various applications owing to its distinctive characteristics. Here are some of the most common applications of this thermoplastic.

1. Automotive Parts

Black ABS plastic is substantially lighter than conventional plastics and widely used in the automotive industry. Automobiles that employ ABS and related plastics can reduce vehicle weight by 10%, making them more fuel efficient. This material is commonly used on dashboards, wheel covers, and body pieces due to its strength, low-temperature resistance, and scratch-resistant surface.

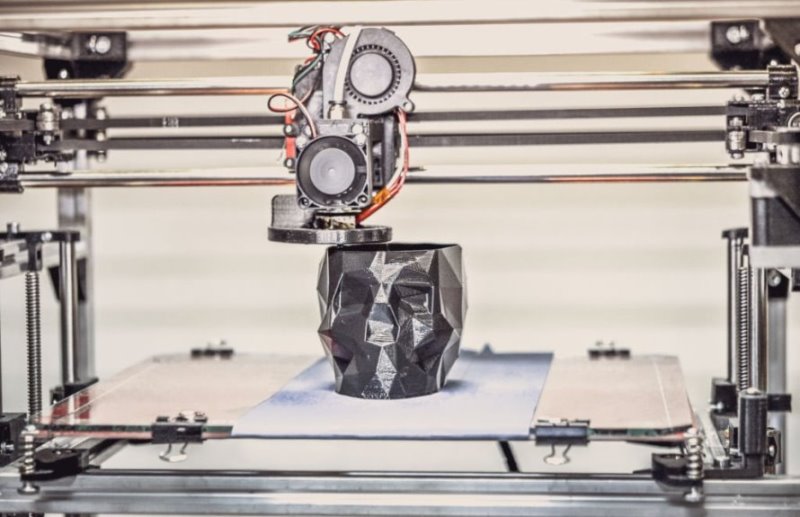

2. 3D printing

ABS plastic is widely used in 3D printing because of its melting point and ability to be molded into various shapes and sizes. ABS plastic sheet is preferred by 3D printing pros over PLA plastic sheet because PLA has a lower melting point, making it difficult to store in warmer temperatures. The black color of ABS plastic is beneficial in 3D printing, as it provides an attractive finish to the final product.

3. Consumer Goods

Consumer goods such as electronic housings like computer keyboards, remote controls, mobile phone cases, and kitchen appliances like blenders and coffee makers also consist of this material. Moreover, the black color of ABS plastic provides a bold and striking appearance, making it ideal for toy manufacturing.

4. Pipes and Fittings

Pipes and fittings manufacturers favor black ABS plastic over other polymers and metals. This material is more durable than PVC and significantly more resistant to impact and breaking in cold temperatures. It is easier to install, lightweight, and will not rot, mold, or corrode when used to collect waste. It's commonly used in plumbing systems for drainage and venting, wastewater treatment, and chemical processing.

5. Vacuum parts

Because of its higher durability compared to other plastics, ABS plastic is an ideal material for making vacuums and vacuum components. The plastic comes with a textured hair-cell surface that resists and hides scratches.

6. Furniture and Fixtures

The usage of black ABS plastic in the furniture and fixtures industry has increased lately due to its durability and aesthetic appearance. It is used to manufacture chairs, tables, shelving units, and bathroom fixtures like shower stalls and tubs.

7. Medical Devices

Besides all the industries mentioned above, black ABS plastic also plays a vital role in manufacturing medical devices due to its biocompatibility and chemical resistance. It is widely used in the medical industry for manufacturing equipment such as medical trays, instrument housings, and drug delivery systems.

EuroPlas black ABS plastic

EuroPlas is one of the world's leading plastic manufacturers, including black ABS plastic. Our black ABS engineering compound has excellent mechanical and thermal properties. It provides superior impact resistance, heat resistance, and dimensional stability, making it ideal for applications that require high-performance materials with excellent surface finish and color consistency.

Black ABS engineering compound can be mixed with a variety of additives and reinforcements following specialized formulas to meet the specific requirements of each end-product. EuroPlas offers a wide range of black ABS compounds with different properties:

- Black ABS flame retardant compound: A blend of ABS resin with flame retardant additives with fire retardant levels V0, V1, and V2, reducing the ease of ignition smoke generation and the rate of burn of plastics

- Black ABS anti-static compound: A combination of ABS plastic and anti-static additives helps limit the electric charge and discharge on plastic surfaces, reducing the risk of fire and explosion.

- Black ABS glass fiber compound: A combination of ABS plastic base with reinforced glass fiber, which increases rigidity and improves the deformation temperature (HDT) and softening temperature (VICAT) of the finished product.

EuroPlas black ABS plastic can be quickly processed by injection molding, extrusion, blow molding, and other processing techniques to produce a wide range of products, such as automotive parts, electronic housings, toys, appliances, and furniture components.

EuroPlas is committed to providing high-quality and reliable black ABS engineering compounds to meet the ever-increasing demands of the global market. With advanced technology, experienced staff, and rigorous quality control, EuroPlas ensures its products are consistent, reliable, and meet the highest performance and quality standards. Contact us for more details about the product.