Expanded Polystyrene (EPS) is a versatile and widely used material known for its exceptional lightweight and durable properties. In this article, we will delve into what EPS is, its properties, and its diverse range of applications. Whether you're in the construction, packaging, or automotive industry,... understanding the benefits of EPS can help you make informed decisions for your projects.

1. What is expanded polystyrene?

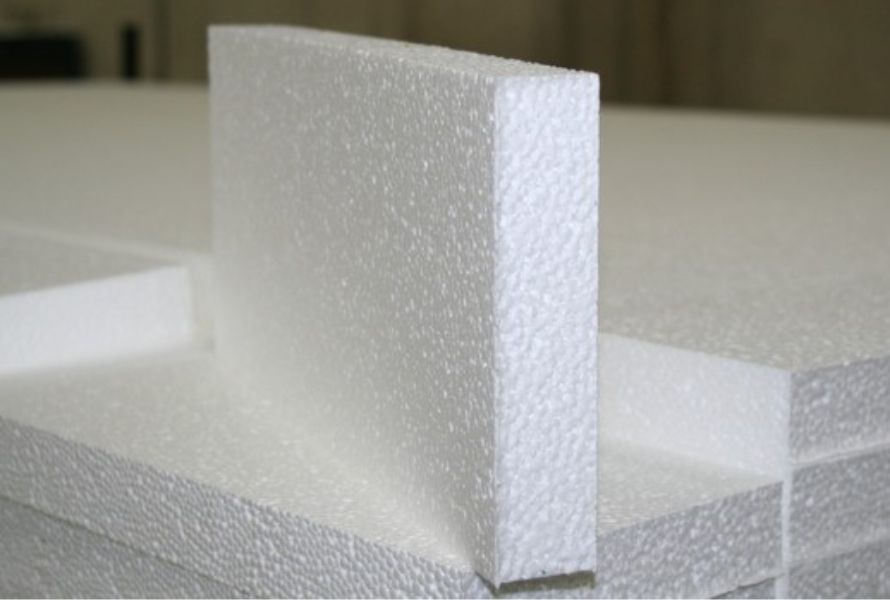

Expanded Polystyrene (EPS) is a type of rigid foam plastic that is derived from polystyrene beads. It is created through a process called expansion, where polystyrene beads are heated and exposed to steam and a blowing agent. This causes the beads to expand and fuse together, forming a lightweight cellular material.

Polystyrene beads are the source of Expanded Polystyrene (EPS), a rigid foam plastic

2. Properties of expanded polystyrene

2.1. Lightweight

Expanded polystyrene is renowned for its lightweight nature. It has a low density, which means it has a high strength-to-weight ratio. This property makes EPS easy to handle, transport, and install. Its lightweight nature also reduces the load on structures, making it an ideal choice for applications where weight is a concern.

Expanded polystyrene is well known for being low-density and lightweight

2.2. Insulation

Expanded polystyrene is widely recognized for its exceptional insulation properties. The closed-cell structure of EPS foam traps air within its cells, creating a barrier that slows down the transfer of heat. This property makes EPS an excellent thermal insulator, helping to maintain stable indoor temperatures and reduce energy consumption for heating and cooling. EPS insulation is commonly used in residential, commercial, and industrial buildings to improve energy efficiency and thermal comfort.

2.3. Durability

Expanded polystyrene is a durable material that can withstand various stresses and impacts. Its closed-cell structure provides strength and resilience, allowing it to maintain its shape and structural integrity even under heavy loads. Expanded polystyrene can absorb and distribute forces, making it suitable for applications where impact resistance is required. This durability of EPS ensures that EPS products can withstand the rigors of transportation, installation, and long-term use.

Expanded polystyrene is a tough material that can withstand a wide range of stresses and impacts

2.4. Moisture Resistance

Expanded polystyrene is inherently resistant to moisture. The closed-cell structure of expanded polystyrene foam prevents the absorption of water, making it resistant to rot, mold, and mildew. This property is particularly beneficial in applications where protection against moisture damage is necessary, such as in insulation materials for roofs, foundations, and below-grade applications. EPS insulation retains its insulating properties even in humid or wet environments.

2.5. Dimensional Stability

Expanded polystyrene exhibits excellent dimensional stability. It retains its shape and size over time, even when subjected to changes in temperature or humidity. This stability ensures that expanded polystyrene products fit and perform as intended, providing consistent insulation and structural support. EPS does not warp, shrink, or expand under normal conditions, making it a reliable material for long-term applications.

2.6. Versatility

Expanded polystyrene is a highly versatile material that can be molded and shaped to meet specific design requirements. It can be manufactured in various densities and thicknesses, allowing for customization based on the desired application. EPS can be easily cut, shaped, and molded into different forms, making it adaptable to a wide range of applications in construction, packaging, automotive, and more.

Expanded polystyrene is a highly adaptable material that can be molded and shaped to meet specific design specifications

2.7. Sound Absorption

Expanded polystyrene possesses good sound absorption properties. Its cellular structure and density help to dampen and absorb sound waves, reducing noise transmission. This makes expanded polystyrene a suitable material for applications where acoustic insulation is desired, such as in building walls, ceilings, or flooring systems. EPS can contribute to creating quieter and more comfortable environments by minimizing the impact of noise.

2.8. Chemical Resistance

Expanded polystyrene is resistant to many chemicals, oils, and solvents. It does not react with common substances, making it suitable for use in various environments without being adversely affected by chemical exposure. This chemical resistance ensures the long-term stability and performance of EPS in applications where exposure to chemicals is a concern.

2.9. Recyclability

Expanded polystyrene is a recyclable material. It can be collected, processed, and reused to create new expanded polystyrene products. Recycling EPS helps reduce waste and conserve valuable resources. The recycling process involves compacting and melting the EPS foam, which can then be used as raw material for manufacturing new EPS products. The recyclability of EPS contributes to environmental sustainability.

It is possible to gather, process, and repurpose expanded polystyrene to make new EPS goods

3. Application of expanded polystyrene

3.1. Construction

Expanded polystyrene is extensively employed in the construction industry for thermal insulation purposes. It is used in the form of rigid foam boards or panels that are installed in walls, roofs, and floors. EPS insulation helps reduce heat transfer, improve energy efficiency, and create comfortable indoor environments. It also serves as a sound barrier, dampening noise transmission between rooms.

Thermal insulation is one of the main uses of EPS in the building industry

3.2. Packaging

Expanded polystyrene is a popular choice for packaging fragile and delicate items. It is used to create protective packaging materials, such as molded foam inserts, corner protectors, and cushioning materials. Expanded polystyrene packaging provides excellent shock absorption and impact resistance, safeguarding products during transportation. It is commonly used in electronics, appliances, glassware, and other delicate items.

3.3. Automotive Industry

Expanded polystyrene is utilized in the automotive sector for various applications. It is used in vehicle interiors for components such as headliners, door panels, armrests, and seat cores. Expanded polystyrene provides lightweight and comfortable solutions while offering sound and thermal insulation properties. EPS is also used as a filler material to reduce weight in non-structural parts of vehicles, improving fuel efficiency.

3.4. Marine and Boating

Expanded polystyrene finds applications in the marine industry for buoyancy and flotation devices. It is used to create floatation modules, buoys, and other marine structures that require lightweight and durable materials. Expanded polystyrene foam is resistant to water absorption and provides reliable buoyancy support for boats, docks, and other marine applications.

In the marine industry, expanded polystyrene is used for flotation and buoyancy devices

3.5. Arts and Crafts

Expanded polystyrene is a favored material for arts and crafts projects. Its lightweight and easy-to-cut nature make it suitable for creating props, sculptures, architectural models, and decorative items. Expanded polystyrene can be easily shaped, carved, and painted, offering artists and crafters a versatile medium for their creative endeavors.

3.6. Insulated Concrete Forms (ICFs)

Expanded polystyrene foam panels are used as building blocks in the construction of Insulated Concrete Forms (ICFs). These forms are stacked and filled with concrete to create insulated walls for residential and commercial buildings. Expanded polystyrene foam provides both insulation and structural support, resulting in energy-efficient and durable structures.

3.7. Geofoam

Expanded polystyrene is employed in geotechnical applications as a lightweight fill material known as geofoam. Geofoam is used to reduce soil loads, provide slope stabilization, and minimize settlement in various civil engineering projects. It is commonly used in road embankments, bridge approaches, underground utilities, and landscape applications.

3.8. Stage and Set Design

Expanded polystyrene foam is utilized in the entertainment industry for stage and set design. It is used to create props, scenery, and backdrops for theater productions, movies, and television shows. EPS foam's lightweight nature, ease of shaping, and affordability make it a preferred choice for creating visually appealing and intricate set designs.

In the entertainment industry, expanded polystyrene foam is used to design stages and sets

4. Conclusion

In summary, expanded polystyrene (EPS) is a highly versatile material with a multitude of applications across industries. Its exceptional insulation properties, lightweight nature, and durability make it a preferred choice for thermal insulation in construction, protective packaging, automotive components, marine flotation devices, and artistic creations. By harnessing the benefits of EPS, you can enhance energy efficiency, ensure product safety during transportation, improve comfort in vehicles, and unlock creative possibilities in various artistic endeavors. With its wide-ranging advantages, EPS continues to be a valuable and reliable solution for diverse industry needs.

If you'd like more information, let’s check out the EuroPlas blog to find out more knowledge about cutting-edge plastic or contact us right now!