Polyamide, often referred to as nylon, is a synthetic polymer that has revolutionized countless industries with its exceptional versatility and performance. In this blog, we will take an in-depth journey into the world of polyamide, uncovering its fascinating properties, exploring its diverse applications, and shedding light on its significant impact on our daily lives.

From clothing and textiles to engineering and manufacturing, polyamide plays a crucial role in a multitude of sectors. Its impressive strength, durability, and flexibility make it a go-to choice for various applications, while its ability to be molded into different shapes and sizes has led to innovative breakthroughs in product design and development.

Join us as we unravel the secrets of polyamide, understanding what makes it such a remarkable material and how it continues to shape the modern world. Whether you're a materials enthusiast, a designer, or simply curious about the materials that surround you, this blog will provide valuable insights into the captivating realm of polyamide.

1. Polyamide

Polyamide, often referred to as nylon, is a synthetic polymer that has left an indelible mark on a multitude of industries, thanks to its remarkable versatility and performance. In this section, we'll delve into the essence of polyamide, understanding its composition and its diverse range of applications.

1.1. What is Polyamide

So what is Polyamide material? It is a type of synthetic polymer renowned for its exceptional strength, durability, and flexibility. The name "polyamide" itself derives from its molecular structure, characterized by the presence of recurring amide linkages along its polymer chain. This unique structure is responsible for many of polyamide's extraordinary properties, including its resistance to wear, tear, and deformation.

One of its standout characteristics is its ability to maintain its integrity under a wide range of conditions. This makes polyamide a top choice for applications demanding toughness and resilience. Whether it's in the form of nylon fabrics, engineering components, or consumer goods, polyamide is known for its ability to withstand mechanical stress, making it invaluable in various sectors.

1.2. What is Polyamide Made of

Polyamide production involves the polymerization of specific chemical compounds, usually derived from petrochemical sources. These raw materials undergo intricate chemical reactions, resulting in the formation of long polyamide chains. The choice of raw materials and the manufacturing process can lead to various types of polyamides, each tailored to specific applications, such as nylon 6, nylon 66, and more.

While traditional polyamides have primarily relied on petrochemical feedstocks, the pursuit of more sustainable alternatives has given rise to bio-based polyamides. These eco-friendly options incorporate renewable resources like plant-based feedstocks, offering a greener alternative to their petroleum-based counterparts.

As we journey through the world of polyamide, we'll uncover its myriad applications and understand how its unique properties continue to shape and enhance various aspects of our daily lives.

Read more: Polyamide vs nylon: Are they the same? What are the differences?

2. Properties of Polyamide

Polyamide, commonly known as nylon, boasts a rich array of properties that have made it a staple material in numerous industries. In this section, we'll explore the key characteristics of polyamide through a concise list:

- Exceptional Strength: Polyamide exhibits high tensile strength, making it resistant to stretching and breaking. It's ideal for applications requiring robust materials like ropes, threads, and fabrics.

- Durability: Polyamide is highly durable, capable of withstanding harsh environmental conditions, including UV radiation, moisture, and chemicals. This durability ensures its longevity in various settings.

- Flexibility: Polyamide's inherent flexibility allows it to be molded into various shapes and sizes, making it suitable for products ranging from toothbrush bristles to high-performance sports equipment.

- Heat Resistance: It can tolerate high temperatures without significant deformation, making it suitable for applications such as automotive components and electrical connectors.

- Chemical Resistance: Polyamide is resistant to many chemicals, ensuring it remains stable in the presence of various substances. This property is crucial in industries like automotive, where it is used in engine components.

- Low Friction: Its low coefficient of friction makes polyamide an excellent choice for bearings, gears, and other components requiring reduced friction for smooth operation.

- Excellent Insulation: It has electrical insulating properties, making it valuable in electrical and electronic applications, including cable insulation and connectors.

- Lightweight: Despite its strength and durability, polyamide is relatively lightweight, contributing to its use in applications where weight is a consideration, such as automotive and aerospace.

- Versatility: Its adaptability to various manufacturing processes and its compatibility with other materials enhance its versatility, allowing for a wide range of applications across industries.

Polyamide's combination of these properties makes it a material of choice in diverse sectors, from fashion and consumer goods to engineering and beyond.

Frequently Asked Questions:

Is Polyamide Toxic?

Polyamide, often known as nylon, is generally considered safe and non-toxic for common applications. It is widely used in various consumer products, including clothing, kitchenware, and medical devices. However, like many materials, the safety of polyamide can depend on its specific formulation and use. In some industrial processes, the production or degradation of certain types of polyamide may release potentially harmful substances.

As a consumer, there is usually no need to be concerned about the toxicity of products made from polyamide. Always follow manufacturer guidelines for proper use and care of polyamide items to ensure safety.

Is Polyamide Natural or Synthetic?

Polyamide is primarily a synthetic polymer, meaning it is chemically produced through polymerization of specific monomers. The most common source of polyamide is petrochemicals. However, advancements in materials science have led to the development of bio-based polyamides, which are derived from renewable resources like plant-based feedstocks.

These bio-based polyamides offer a more sustainable alternative to traditional, petroleum-based polyamides while retaining many of the material's desirable properties. So, while the majority of polyamide is synthetic, there are eco-friendly options that have a natural component in their production.

3. Applications of Polyamide

Polyamide, commonly known as nylon, finds its way into a vast array of applications across diverse industries, thanks to its exceptional properties. Here, we'll explore some of the most prominent uses of this versatile material.

3.1. Textiles and Apparel:

Perhaps one of the most well-known applications of polyamide is in the textile industry. Nylon fabrics are prized for their durability, elasticity, and resistance to abrasion. They're used to create a wide range of clothing items, including stockings, swimwear, and sportswear.

3.2. Automotive Components:

Polyamide's strength and resistance to heat and chemicals make it an ideal choice for various automotive parts. It's used in components like engine covers, air intake manifolds, and fuel lines.

3.3. Engineering and Manufacturing:

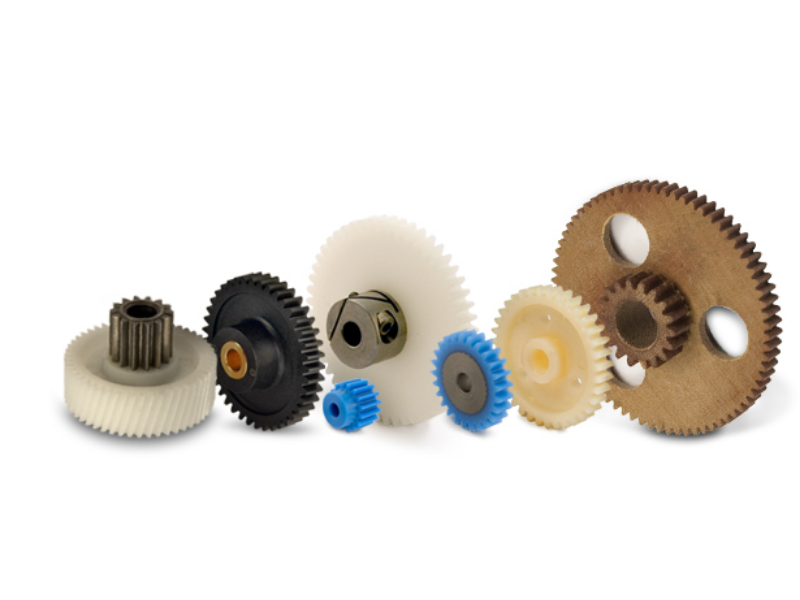

In engineering, polyamide is employed to craft high-strength components, such as gears, bearings, and bushings. Its low friction coefficient and self-lubricating properties make it suitable for applications where reduced friction is crucial.

3.4. Packaging Materials:

Polyamide's barrier properties against moisture and oxygen make it valuable for packaging perishable goods. It's often used in flexible packaging for food products, helping extend shelf life.

3.5. Consumer Goods:

From toothbrush bristles to zippers, polyamide's versatility is evident in various everyday consumer items. It's chosen for its lightweight yet robust characteristics.

3.6. Electrical and Electronics:

Polyamide's electrical insulation properties make it valuable in the electrical and electronics industry. It's used for cable insulation, connectors, and circuit breakers.

3.7. Medical Devices:

In the medical field, polyamide is utilized for surgical sutures and the production of various medical devices due to its biocompatibility and strength.

Polyamide's adaptability to different manufacturing processes, along with its exceptional properties, has solidified its role as a versatile material that continues to push the boundaries of innovation in various sectors. Its wide-ranging applications showcase the incredible impact of polyamide in our daily lives and industries worldwide.

Nestled in Vietnam, EuroPlas takes immense pride in its role as a premier masterbatch manufacturer. With a legacy spanning over 15 years, we've been committed to exporting innovative plastic solutions to more than 85 countries globally. Our journey has been defined by expertise, state-of-the-art facilities, and an unyielding dedication to sustainability, positioning us as your trusted ally in shaping a greener and more eco-conscious future.

Tailored Solutions for Your Industries: Our cutting-edge technology and unique natural resources empower us to customize products for various industries, meeting their distinct requirements. From cost-effective alternatives to environmentally responsible choices, EuroPlas shines as a beacon of excellence and innovation in the plastic industry.

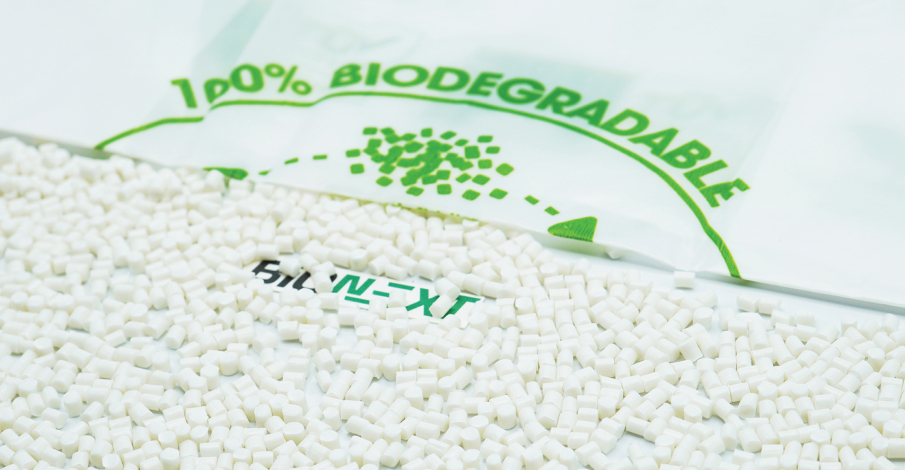

EuroPlas takes a bold stride towards a more sustainable future with its bioplastic compound. Crafted from natural starch and biodegradable additives, this unique solution enables plastic items to biodegrade within a year while maintaining optimal performance. With applications spanning food packaging, agricultural films, and more, our bioplastic compound underscores our unwavering commitment to environmental sustainability.

Our dedication to sustainability continues with the bio filler—an eco-friendly alternative that renders plastic items biodegradable within a year. Comprising natural starch and biodegradable additives, this innovative product finds its purpose in food packaging, disposable tableware, and agricultural films, contributing to a greener future without compromising functionality.

EuroPlas' groundbreaking filler masterbatch is engineered to reduce production costs while enhancing the properties of plastic products. By incorporating filler materials like calcium carbonate or talc, this solution improves stiffness, heat resistance, opacity, and printability. With applications in various industries such as blowing films, injection molding, extrusion, and thermoforming, our filler masterbatch plays a pivotal role in optimizing plastic production.

We recognize the significance of aesthetics, and EuroPlas' color masterbatch delivers precise and consistent colors for a wide range of products, from toys to household appliances and cosmetics. Infused with high-quality pigments and additives, our color masterbatch ensures vibrant and appealing designs that resonate with market demands.

Our comprehensive array of plastic additives forms the cornerstone for enhancing production efficiency and product functionality across industries. From slip agents to anti-block, anti-static, anti-oxidants, and UV stabilizers, EuroPlas' additives elevate the performance and longevity of plastic products while contributing to waste reduction and sustainability.

For those seeking high-performance solutions, EuroPlas offers engineering plastic compounds that blend engineering resins with various additives. This synergy enhances mechanical, thermal, electrical, optical, and chemical properties, catering to industries like automotive, electronics, and medical devices. Our engineering plastic compounds adhere to stringent industry standards and surpass competitors, exemplifying our dedication to excellence.

EuroPlas' diverse product range underscores our commitment to crafting a more sustainable and innovative future. With a focus on quality, performance, and environmental consciousness, we continue to make a meaningful impact on the global plastic industry.

Thank you for considering EuroPlas as your partner for cutting-edge plastic solutions. Our dedicated team is poised to provide expert guidance and support to meet your unique requirements. Whether you have inquiries about our products, need customized solutions, or wish to collaborate on sustainable initiatives, we are here to assist you—reach out to us today!