Self-healing plastics represent a groundbreaking innovation in materials science, designed to autonomously repair damage and extend the lifespan of products. In this article, we'll explore the intricacies of self-healing plastics, how they work, and their benefits.

1. What is Self-Healing Plastic

Self-healing plastic is one kind of polymer that may be automatically healed from its cracks or scratches and similar other damages. By certain embedded chemical properties in materials for the restoration of its structures and functionality, this can be done.

These kinds of plastics, by inbuilt self-healing capabilities, prevent waste and high maintenance costs for better sustainability in the life cycles of products.

Self-healing plastic is capable of autonomously repairing damage.

2. Mechanisms Behind Self-Healing Plastic

2.1. Intrinsic self-healing

Intrinsic self-healing plastic depends on the inherent structure of the material's molecular level. Key features are as follows:

- Dynamic bonds: The polymers contain dynamic chemical bonds, which may be hydrogen bonds or reversible covalent bonds. These bonds can break apart and reform. In this way, if a crack or scratch happens, the bonds can reconnect and give the material its original structure and properties.

- Molecular mobility: The possibility of movement or rearrangement of the polymer chains is vital. In cases of damage, the mobility of the chains allows the rearrangement of molecules around the fracture, thus healing the material without the use of external elements.

2.2. Extrinsic self-healing

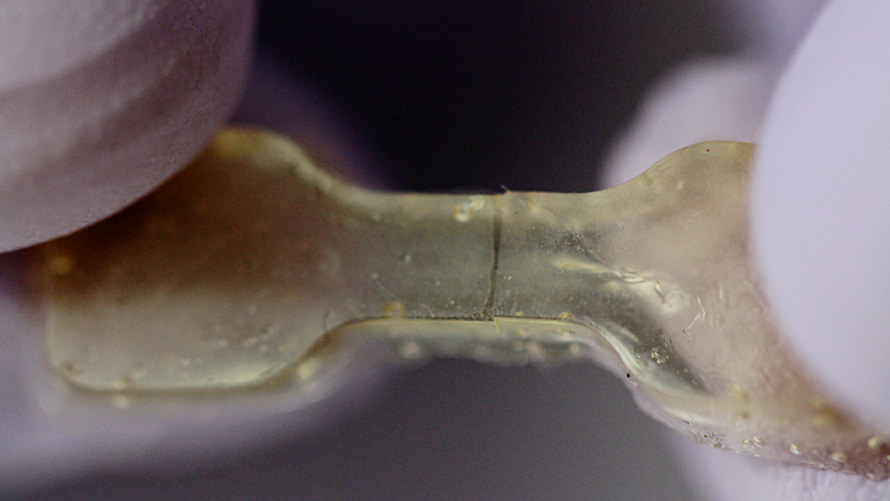

Extrinsic self-healing plastic is a material that requires the incorporation of other components to achieve the self-healing effect. The critical factors for this process include:

- Microcapsules: Small capsules filled with self-healing agents, such as adhesives or monomers. The opening of capsules by the appearance of cracks allows the healing agents to reach the site of damage; there, they polymerize or crosslink, sealing the crack.

- Vascular systems: Like biological systems, a number of self-healing materials have vascular systems that carry the healing agent to the location of damage. These can be designed to provide healing agents when required, enabling a rapid response to any damage.

- Healing agents: The selection of healing agents is very important for effective healing. The agents should be compatible with the polymer matrix and have to form strong chemical bonds in the healing process.

3. Scientific Advancements in Self-Healing Technology

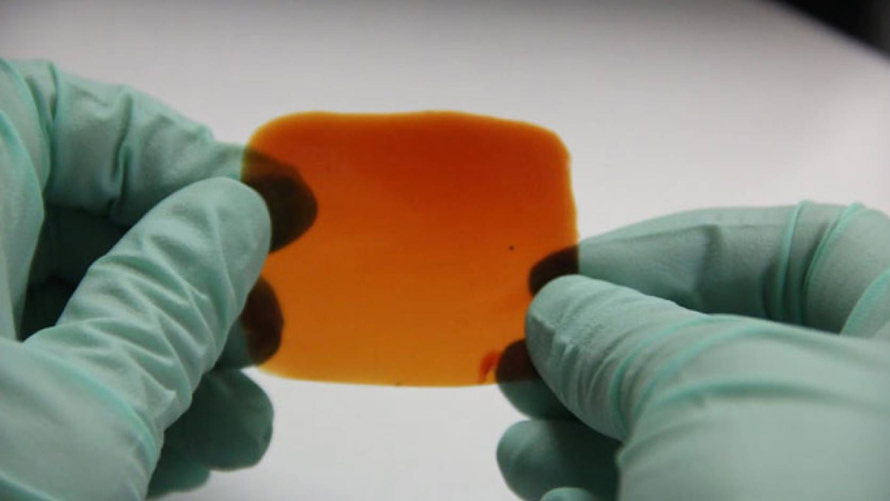

3.1. Development of new polymers

Further development of new polymers is on while having approaches to explore polymers that can improve the self-healing ability. Therein, bio-based polymers can in some way promote self-healing because of their innate structures. Moreover, thermoplastic elastomers combined with the elasticity of rubber and toughness of plastic are very promising polymers for self-healing applications.

New polymers are being developed in the field of self-healing technology.

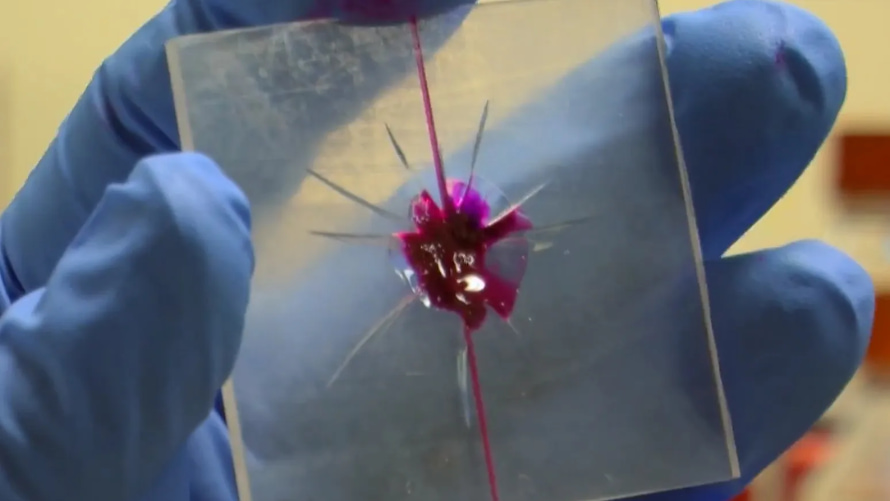

3.2. Enhanced healing agents

The efficiency of an extrinsic self-healing mechanism depends on advanced healing agents. Scientists are creating increasingly sophisticated and smart agents that will react to environmental stimuli, for example, heat or light, and activate an efficient healing mechanism. The progress in microencapsulation helps to gain control over the release of these agents in order to ensure activation only at the corresponding moment when it is required.

3.3. Integration of nanotechnology

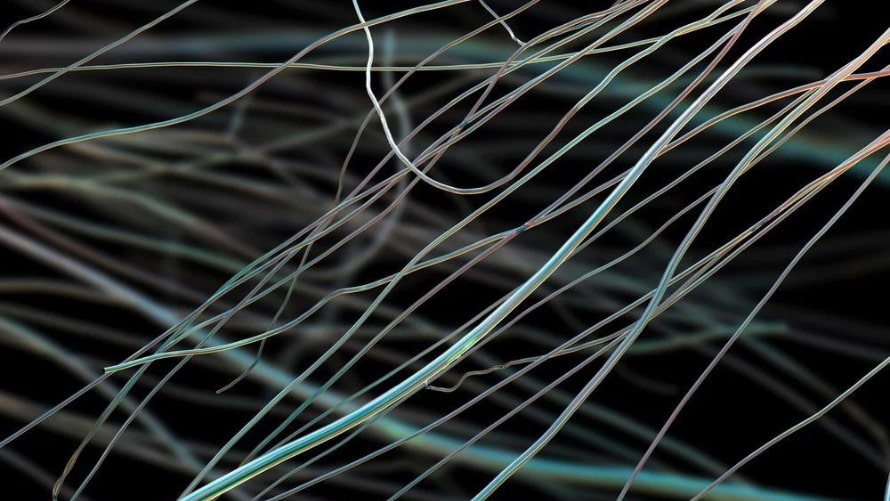

Nanotechnology greatly reinforces the self-healing plastics. The incorporation of nanoparticles improves mechanical strengths and effects of healing; some act as catalysts that speed up the repair process. Moreover, self-healing nanofibers composites give structural strengthening and improve overall performances.

Self-healling nanofibers

3.4. Advances in vascular networks

Vascular networks in self-healing plastics have been developed to allow tuning the repair routes. The networks can deliver therapeutic agents to the damaged site. Research is ongoing to develop self-regulating systems that can sense damage and release agents to enhance material plasticity.

4. Benefits of Self-Healing Plastic

4.1. Increased durability

The self-healing plastics are able to repair themselves without human or mechanical intervention and should therefore last longer than ordinary plastics. This means less replacement/ maintenance, so the applications put in place will be extremely durable.

Self-healing plastics increase the products’ durability

4.2. Cost-effectiveness

Thanks to the increase in durability, this automatically results in cost reductions in the long run almost from the very instance of its implementation. The less the frequency of repairs and replacement, the cheaper the expenses that are incurred on the material. Self-healing plastics are therefore advantaged economically to both producer and consumer and they are appreciated in other fields where safety and reliability prevail.

4.3. Sustainability

Self-healing plastics reduce waste, thereby, sustainability is increased. They help to extend the span of products and thus minimize the environmental impacts arising from the manufacturing or disposal of conventional plastics. This fully corresponds to modern global initiatives to go green and sustainable.

4.4. Enhanced safety

Both in critical facilities such as medicine, and structural applications such as in airplanes among others, self-healing plastics can eliminate risks with regards to possible failure of such plastics. These materials are useful in repairing all sorts of damages hence making it hard for products to have a failure and therefore enhancing reliability.

4.5. Versatility

Self-healing plastics can be developed for various applications, which range from electronic packaging and automotive parts. This versatility is given to those manufacturers who have developed the incorporation of self-healing properties into different products for the varying needs of various industries.

Self-healing plastics can be universally applied in various industries.

4.6. Improved aesthetics

The ability of self-healing materials to maintain their appearance through scratch and minor damage repair products goes a long way for consumer goods. Such an advantage in aesthetics greatly increases the quality and attraction of things such as cell phones, automotive finishes, and household products.

5. Conclusion

Self-healing plastics may change almost every industry operating today when it can repair itself in order to increase usability and safety, while helping in sustainability. When research is developing continuously, we can expect to get more responsible applications and innovations in self-healing technology.

6. About EuroPlas

EuroPlas is a well-known company engaged in the production of high-quality plastic compounds and additives.

The products offered by us include bioplastic compounds, engineering plastic compounds, color masterbatches, plastic additives, filler masterbatches, and biofillers. These value-added products are bound to enhance the performance, durability, and aesthetic appeal of plastic materials across various applications.

Contact us now for more support!