Nylon 6 is a highly versatile synthetic polymer that has become a fundamental material in the medical industry. Its exceptional strength, flexibility, and biocompatibility make it ideal for manufacturing surgical tools, implants, and other essential medical devices. This adaptable material offers several unique advantages, including resistance to chemicals and compatibility with sterilization processes, ensuring reliability in demanding healthcare applications. In this article, we will explore the definition, properties, and impact of Nylon 6 material on the medical industry.

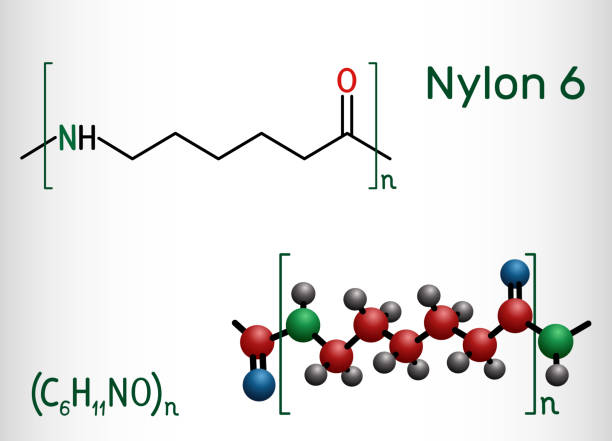

Nylon 6, known as polycaprolactam, is a popular polyamide polymer used in various industries. Unlike most other nylon types, it is made through a process called ring-opening polymerization, not condensation polymerization.

Read more: Nylon 6: Definition, properties and common uses

Nylon 6 material

2. Applications of Nylon 6 in the Medical Industry

2.1. Surgical Sutures

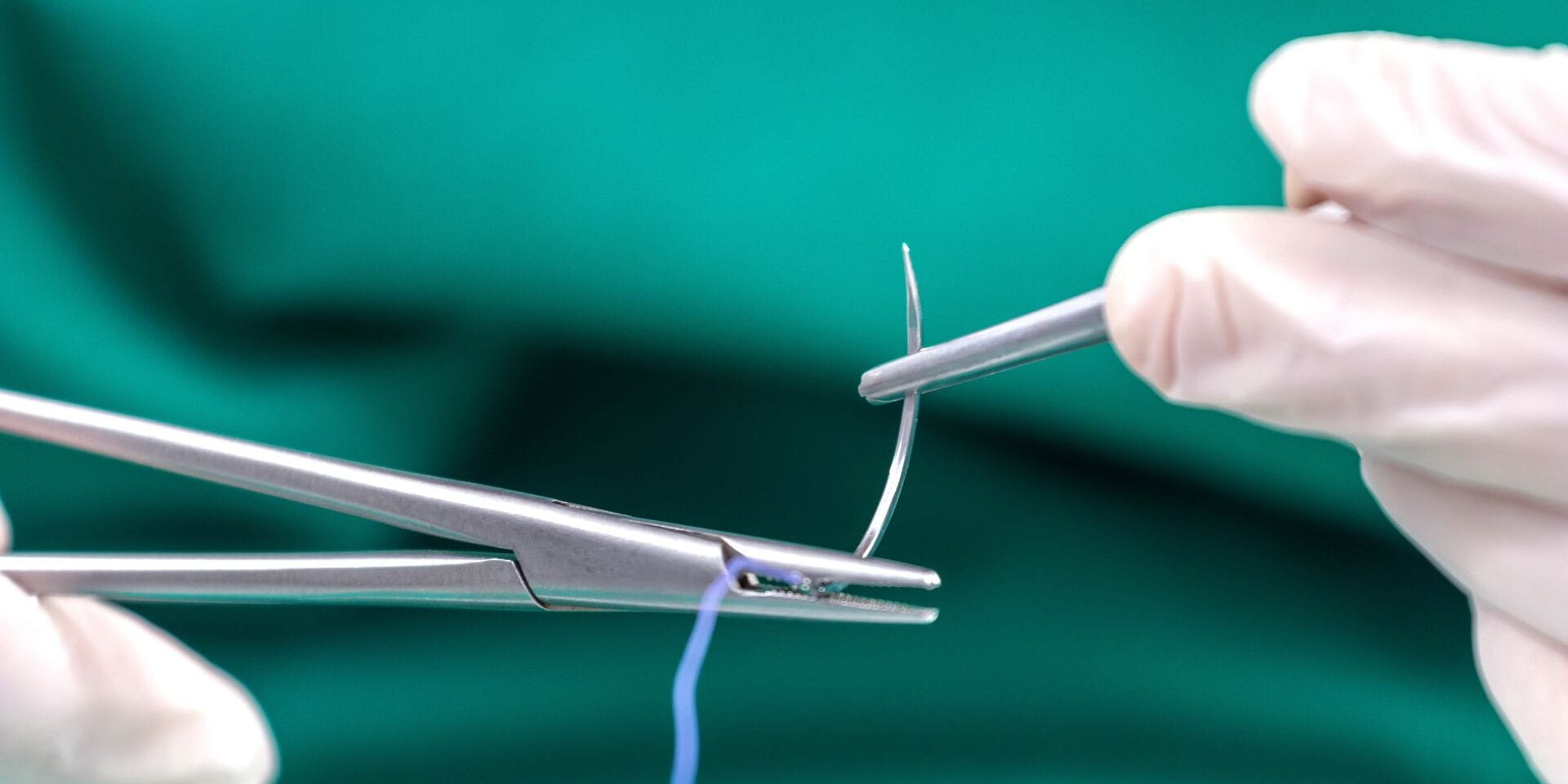

Nylon 6 material is widely used in the production of surgical sutures due to its strength, flexibility, and biocompatibility. These sutures are essential for closing wounds during surgeries and promoting healing. Nylon 6 sutures are smooth, which minimizes tissue irritation and reduces the risk of infection.

They can be made as monofilament for smoother passage through tissues or braided for added strength. The durability of Nylon 6 ensures that the sutures securely hold the wound until healing is complete. Its resistance to stretching and breaking makes it a reliable choice for both internal and external sutures in various medical procedures.

Surgical sutures made by nylon 6 material

2.2. Catheters and Tubing

Nylon 6 is an excellent material for manufacturing catheters and medical tubing due to its flexibility, strength, and chemical resistance. These qualities ensure that the devices are durable and safe for medical use. Nylon 6 tubing can meet the precision required for medical procedures, allowing for the smooth transfer of fluids and medications. Its resistance to chemicals and sterilization processes makes it reliable for repeated use.

Furthermore, the material’s biocompatibility ensures it functions safely within the human body, minimizing the risk of adverse reactions. As a result, Nylon 6 is commonly used in various medical tubing applications, including intravenous lines and urinary catheters, thereby enhancing patient care and safety.

Catheters and Tubing

2.3. Sterilization Trays and Surgical Instruments

Nylon 6 material is widely used to make sterilization trays and surgical instruments because of its durability and heat resistance. These trays play a crucial role in holding and protecting medical tools during sterilization processes. Nylon 6 can withstand high temperatures and harsh conditions in autoclaves or chemical sterilizers without losing its shape or properties.

For surgical instruments, Nylon 6 provides a firm, ergonomic grip while being resistant to wear and corrosion. These qualities ensure reliable performance, making Nylon 6 a trusted material for reusable medical equipment in healthcare facilities.

2.4. Prosthetics and Orthotics

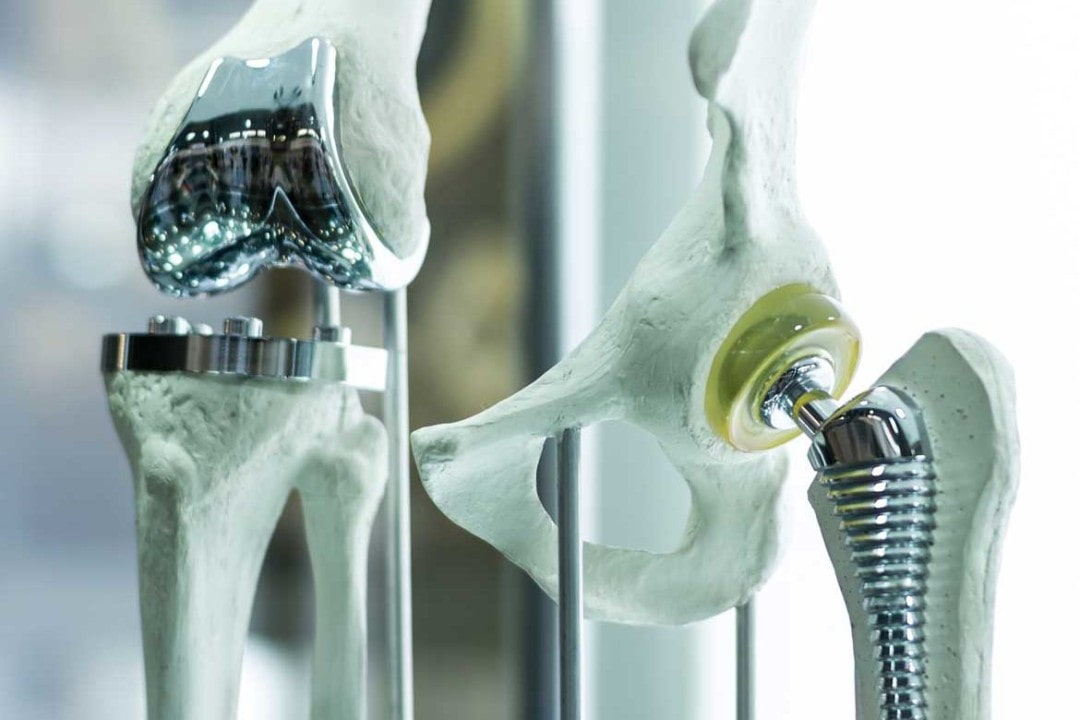

Nylon 6 is a valuable material in the production of prosthetics and orthotics. It is commonly used to manufacture joint sockets, structural frames, and other components that require durability and precision. The adaptability of Nylon 6 allows for custom designs tailored to meet the specific needs of patients, enhancing both comfort and functionality.

Furthermore, its resistance to wear and impact ensures long-lasting performance, even with daily use. By providing a reliable and affordable option, Nylon 6 significantly improves the quality of life for individuals who rely on prosthetic or orthotic devices.

2.5. Medical Implants

Nylon 6 material is widely utilized in medical implants due to its strength, lightweight nature, and biocompatibility. It is commonly used in orthopedic implants such as bone screws, plates, and pins, providing reliable support for healing bones and joints. The material's durability allows it to withstand physical stress without breaking, while its lightweight properties reduce additional strain on the body. Biocompatible grades of Nylon 6 are safe for use in the human body, minimizing the risk of adverse reactions. Its versatility and ease of shaping make Nylon 6 a practical choice for creating effective and affordable medical implants.

Medical Implants

3. Advantages of Using Nylon 6 in Healthcare

Nylon 6 possesses numerous advantages that make it an excellent material for healthcare applications. Its unique properties address the demanding requirements of medical devices, tools, and applications, ensuring safety, efficiency, and long-lasting performance.

3.1. Biocompatibility

Biocompatibility is one of the most significant advantages of Nylon 6 in the healthcare field. This means it can safely interact with the human body without causing harm or irritation. Special grades of Nylon 6 are designed to meet stringent medical standards, making it suitable for use in items such as surgical sutures, implants, and catheters.

Its ability to minimize reactions with tissues or bodily fluids ensures patient safety during medical procedures. Whether used temporarily, as in sutures or permanently, like in implants, Nylon 6 offers a reliable and safe solution for healthcare applications that require high compatibility with the human body.

3.2. Chemical Resistance

Nylon 6 is highly resistant to many chemicals, making it an ideal material for healthcare applications. It can withstand exposure to bodily fluids, cleaning agents, and sterilization chemicals without breaking down or losing its properties. This chemical resistance ensures that medical devices, such as catheters, tubing, and surgical instruments, remain safe and functional during use.

Additionally, Nylon 6 can endure repeated sterilization processes, which are essential for maintaining hygiene in medical settings. Its ability to resist corrosion and chemical reactions helps extend the lifespan of medical equipment, making it a reliable choice for both single-use and reusable healthcare applications.

3.3. Strength and Durability

Nylon 6 material is known for its excellent strength and durability, making it a trusted material in healthcare. Its high tensile strength allows it to handle heavy loads and physical stress, which is essential for medical devices like surgical tools, implants, and prosthetics.

Nylon 6 also resists wear and tear, ensuring long-lasting performance in demanding medical environments. This durability makes it suitable for equipment that undergoes frequent use and sterilization.

By maintaining its shape and reliability over time, Nylon 6 helps create medical products that are safe, effective, and able to withstand the challenges of daily healthcare applications.

Nylon 6 is a strength and durability material

3.4. Cost-effective

Nylon 6 is a cost-effective material widely used in healthcare. Compared to metals or ceramics, it offers a more affordable option without compromising performance or safety.

Its lightweight nature reduces manufacturing and transportation costs, while its strength and durability ensure long-lasting medical devices, minimizing the need for frequent replacements.

By choosing Nylon 6, healthcare providers can access reliable, high-performing medical products while keeping costs manageable, making healthcare more accessible and affordable for patients.

4. Challenges in Using Nylon 6 in Medical Applications

While Nylon 6 offers many advantages in healthcare, it also comes with challenges that need to be addressed. A significant issue is its tendency to absorb moisture from the environment, which can weaken the material and alter its properties, such as strength and flexibility.

This change can impact its performance in specific medical applications. Another challenge is its limited heat resistance. Nylon 6 can handle moderate temperatures but may deform or lose its shape when exposed to high heat for extended periods.

This limitation restricts its use in medical tools or devices that require high-temperature sterilization. Additionally, nylon 6 is not biodegradable, which raises concerns about its environmental impact, especially for disposable medical products.

Efforts are being made to recycle or develop more eco-friendly alternatives, but these solutions are not always widely available.

5. Conclusion

In short, nylon 6 has made a significant impact on the medical industry, offering a versatile and reliable solution for various applications, from sutures to implants. Its strength, biocompatibility, and adaptability make it an essential material in healthcare.

However, challenges such as moisture absorption and environmental concerns need to be addressed to fully harness its potential. As the demand for advanced medical materials grows, Nylon 6’s role will continue to expand, driving innovations and improving patient care. With continued research and development, this remarkable polymer is poised to play an even greater role in shaping the future of healthcare.

6. About EuroPlas

EuroPlas is a global leader in plastic masterbatch manufacturing, known for its commitment to innovation, quality, and sustainability. The company provides a wide range of high-performance masterbatch solutions designed to enhance the functionality and aesthetics of plastic products. EuroPlas offers products such as bioplastic compounds, color masterbatch, plastic additives, engineering plastic compounds, filler masterbatch and bio filler. With cutting-edge technologies and extensive expertise, EuroPlas ensures its products meet the highest industry standards. By prioritizing customer needs and fostering strong relationships, EuroPlas plays a vital role in advancing the global plastics industry.

For more information and samples, please contact us HERE!