Is Nylon UV resistant? Nylon is a versatile and durable material that has many applications in various industries. But how does it fare against the sun’s rays? Is Nylon uv resistant or does it degrade over time? In this article, we will answer these questions and provide some tips on how to improve UV resistance in nylon.

1. What is Nylon?

Nylon is a synthetic polymer that belongs to the family of polyamides. It was invented in 1935 by Wallace Carothers at DuPont as a substitute for silk. Nylon can be formed into fibers, filaments, sheets, films, or molded parts. It has many desirable properties, such as:

- High strength and toughness

- Good abrasion and wear resistance

- Low coefficient of friction

- Good elasticity and resilience

- Good chemical resistance

- Good thermal stability

- Good electrical insulation

Nylon is widely used in textiles, clothing, carpets, ropes, nets, parachutes, tires, gears, bearings, hoses, gaskets, seals, and many other products.

Engineering plastic compounds Nylon 6

Engineering plastic compounds Nylon 6

2. Is Nylon UV resistant? Properties of Nylon

Is Nylon UV resistant? Nylon has different types and grades, depending on the number and arrangement of the monomers that make up the polymer chain. The most common types are nylon 6, nylon 6/6, nylon 11, and nylon 12. Each type has its own characteristics and advantages.

Some of the general properties of nylon are:

- Density: 1.13 - 1.15 g/cm3

- Melting point: 210 - 260 °C

- Glass transition temperature: 40 - 90 °C

- Tensile strength: 40 - 120 MPa

- Elongation at break: 15 - 300%

- Modulus of elasticity: 1 - 4 GPa

- Impact strength: 20 - 150 kJ/m2

- Hardness: 80 - 120 Shore D

- Flammability: Self-extinguishing

Is nylon UV resistant?

3. Is Nylon UV resistant? Application of Nylon

Is Nylon UV resistant? Nylon has a wide range of applications in various industries, such as:

- Textile industry: Nylon is used to make fabrics for clothing, sportswear, lingerie, swimwear, hosiery, socks, underwear, jackets, coats, rainwear, etc. Nylon fabrics are lightweight, durable, wrinkle-resistant, quick-drying, and easy to wash.

- Automotive industry: Nylon is used to make parts for cars, trucks, buses, motorcycles, etc. Nylon parts are resistant to heat, oil, grease, gasoline, and other chemicals. Nylon parts include airbags, seat belts, hoses, cables, connectors, filters, gears, bearings, bushings, etc.

- Aerospace industry: Nylon is used to make parts for airplanes, helicopters, rockets, satellites, etc. Nylon parts are strong, lightweight, and able to withstand high temperatures and pressures. Nylon parts include parachutes, ropes, nets, cords, straps, etc.

- Medical industry: Nylon is used to make devices and equipment for medical purposes. Nylon devices are biocompatible, sterilizable, and resistant to infection and corrosion. Nylon devices include sutures, catheters, tubing, implants, prosthetics, etc.

Is nylon uv resistant applying sun-protective clothing

4. Is Nylon UV Resistant?

Is Nylon UV resistant? Nylon is not inherently UV resistant. Prolonged exposure to UV radiation from sunlight can cause the material to degrade, lose strength, and become brittle over time. However, UV resistance can be improved by adding UV stabilizers or protective coatings during the manufacturing process.

UV radiation is a form of electromagnetic radiation that has a wavelength range of 10 - 400 nanometers (nm). It can be divided into three categories:

- UVA: 315 - 400 nm

- UVB: 280 - 315 nm

- UVC: 100 - 280 nm

UVA is the most abundant type of UV radiation on Earth’s surface. It can penetrate deep into the skin and cause premature aging, wrinkles, and skin cancer. UVB is less abundant but more energetic than UVA. It can damage the DNA of cells and cause sunburns, inflammation, and skin cancer. UVC is the most energetic but least abundant type of UV radiation on Earth’s surface. The ozone layer mostly absorbs it and does not reach the ground. However, it can be generated by artificial sources such as germicidal lamps and welding arcs. The skin and eyes may suffer significant harm.

Nylon is sensitive to UV radiation in the wavelength range of 290 - 315 nm. This is known as the material’s spectra maxima. Nylon absorbs UV radiation and undergoes photo-oxidation, which is a chemical reaction that breaks down the polymer chains and produces free radicals. These free radicals can further react with oxygen and other molecules and cause chain scission, cross-linking, or branching. These changes affect the molecular structure and properties of nylon.

Some of the effects of UV radiation on nylon are:

- Discoloration: Nylon can fade or change color when exposed to UV radiation. This is due to the formation of chromophores, which are groups of atoms that absorb visible light and reflect a certain color. For example, nylon can turn yellow or brown when exposed to UV radiation.

- Embrittlement: Nylon can lose its flexibility and elasticity when exposed to UV radiation. This is due to the loss of molecular weight and chain mobility caused by chain scission and cross-linking. Nylon can become stiff, hard, and brittle when exposed to UV radiation.

- Cracking: Nylon can develop cracks or fractures when exposed to UV radiation. This is due to the formation of microvoids or microcracks in the material caused by chain scission and cross-linking. Nylon can crack or break when exposed to UV radiation.

Is Nylon UV resistant? It is a very good UV-resistant nylon.

5. Is Polypropylene or Nylon More UV-Resistant?

Polypropylene is another common synthetic polymer that belongs to the family of polyolefins. It was invented in 1954 by Giulio Natta and Karl Rehn at Montecatini as a thermoplastic with high crystallinity and low density. Polypropylene can be formed into fibers, filaments, sheets, films, or molded parts. It has many desirable properties, such as:

- High stiffness and strength

- Good impact and fatigue resistance

- Good chemical resistance

- Good thermal stability

- Good electrical insulation

- Low cost

Polypropylene is widely used in packaging, textiles, carpets, ropes, nets, medical devices, automotive parts, pipes, containers, toys, and many other products.

However, like nylon, polypropylene is not naturally resistant to UV radiation. In fact, polypropylene is more susceptible to degradation by UV radiation than nylon in its base form (i.e., no pigment or additives). The material becomes brittle after prolonged exposure. For example, basic polypropylene can lose up to 70% of its mechanical strength after six days of exposure to high-intensity UV radiation.

Polypropylene is sensitive to ultraviolet wavelengths of 290 - 300 nm, 330 nm, and 370 nm. These are considered the spectra maxima of polypropylene. Even though polypropylene has great mechanical strength and is highly chemically resistant, it is not suited for prolonged exposure to sunlight. Polypropylene is also not easy to coat so it’s best to simply keep this material out of direct sunlight altogether.

|

Material

|

UV Resistance

|

Advantages

|

Disadvantages

|

|

Nylon

|

Low

|

High strength, abrasion resistance, elasticity, and thermal stability

|

Degradation, discoloration, and brittleness when exposed to sunlight

|

|

Polypropylene

|

High

|

Lightweight, durable, flexible, and resistant to heat, chemicals, and moisture

|

Susceptible to oxidation, thermal degradation, and stress cracking

|

6. How to Make Nylon UV-Resistant Better?

As mentioned earlier, Is Nylon UV resistant? Nylon’s UV resistance can be improved by adding UV stabilizers or protective coatings during the manufacturing process. These additives can either absorb or reflect UV radiation and prevent it from reaching the polymer chains. They can also scavenge free radicals and inhibit photo-oxidation reactions.

Some examples of UV stabilizers for nylon are:

- Hindered amine light stabilizers (HALS): These are organic compounds that contain nitrogen atoms attached to bulky groups. They act as radical scavengers and interrupt the photo-oxidation cycle. They are effective against both UVA and UVB radiation.

- Benzophenone derivatives: These are organic compounds that contain two benzene rings connected by a carbonyl group. They act as UV absorbers and convert UV radiation into harmless heat. They are effective against UVA radiation.

- Benzotriazole derivatives: These are organic compounds that contain three benzene rings fused together with a nitrogen atom at each corner. They act as UV absorbers and convert UV radiation into harmless heat. They are effective against both UVA and UVB radiation.

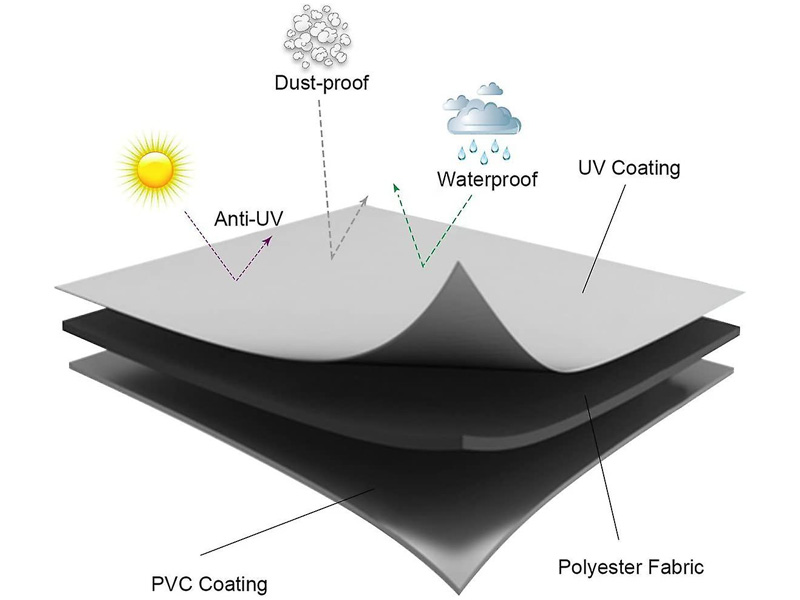

Some examples of protective coatings for nylon are:

- Acrylic compounds: These are synthetic polymers that contain acrylic acid or methacrylic acid derivatives. They form a transparent film on the surface of nylon that protects it from UV radiation. They also improve the gloss and appearance of nylon.

- Epoxy compounds: These are synthetic polymers that contain epoxide groups that can react with curing agents or hardeners. They form a hard and durable film on the surface of nylon that protects it from UV radiation. They also improve the adhesion and corrosion resistance of nylon

Is Nylon UV resistant? Improve UV resistance by adding additives

7. Are UV Resistance Levels Distinct

As we have seen, Is Nylon UV resistant? Nylon is not naturally resistant to UV radiation, but it can be improved by adding UV stabilizers or protective coatings. However, not all nylon types have the same level of UV resistance. Some nylon types are more resistant to UV rays than others, depending on their molecular structure and composition.

Some of the factors that affect the UV resistance of nylon types are:

- The number of carbon atoms in the monomer: Nylon types are named according to the number of carbon atoms in the monomer that forms the polymer chain. For example, nylon 6 has six carbon atoms in its monomer, while nylon 6/6 has two monomers with six carbon atoms each. Generally, the higher the number of carbon atoms in the monomer, the higher the UV resistance of the nylon type. This is because more carbon atoms provide more shielding and protection for the polymer chain from UV radiation.

- The presence of aromatic rings in the monomer: Some nylon types have aromatic rings in their monomer, which are cyclic structures that contain six carbon atoms and alternating single and double bonds. For example, nylon 6T has an aromatic ring in its monomer, while nylon 6 does not. Aromatic rings can enhance the UV resistance of nylon types by absorbing UV radiation and dissipating it as heat.

- The presence of other functional groups in the monomer: Some nylon types have other functional groups in their monomer, such as amides, esters, ethers, or sulfones. These functional groups can affect the UV resistance of nylon types by altering their polarity, solubility, crystallinity, or cross-linking ability.

Based on these factors, some examples of nylon types with different levels of UV resistance are:

- Nylon 6: This is one of the most common and widely used nylon types. It has a low level of UV resistance due to its low number of carbon atoms and lack of aromatic rings or other functional groups in its monomer. It can degrade rapidly when exposed to sunlight and lose its strength and flexibility.

- Nylon 6/6: This is another common and widely used nylon type. It has a slightly higher level of UV resistance than nylon 6 due to its higher number of carbon atoms in its monomer. However, it still lacks aromatic rings or other functional groups in its monomer and can degrade over time when exposed to sunlight.

- Nylon 11: This is a specialty nylon type that is derived from a renewable source (castor oil). It has a high level of UV resistance due to its high number of carbon atoms and presence of an ester group in its monomer. It can retain its mechanical properties and color stability even after prolonged exposure to sunlight.

- Nylon 12: This is another specialty nylon type that is derived from a petroleum source (laurolactam). It has a high level of UV resistance due to its high number of carbon atoms and presence of an ether group in its monomer. It can resist degradation and discoloration even after prolonged exposure to sunlight.

- Nylon 6T: This modified nylon type has an aromatic ring in its monomer. It has a very high level of UV resistance due to its high number of carbon atoms and an aromatic ring in its monomer. It can absorb UV radiation and dissipate it as heat without affecting its molecular structure or properties.

Therefore, depending on your application and environment, you may want to choose a nylon type that has a suitable level of UV resistance for your needs.

|

Nylon Variation

|

UV Resistance

|

Advantages

|

Disadvantages

|

|

Nylon 6/6

|

Low

|

High strength, stiffness, and heat resistance

|

Degradation, discoloration, and brittleness when exposed to sunlight

|

|

Nylon 6

|

Medium

|

High strength, toughness, and elasticity

|

Susceptible to hydrolysis and oxidation

|

|

Nylon 12

|

High

|

High flexibility, impact resistance, and chemical resistance

|

Lower mechanical strength and thermal stability than nylon 6/6

|

8. Nylon vs Other Materials for Outdoor Use

There are other materials than nylon that may be utilized for outdoor purposes. In terms of UV resistance, toughness, comfort, price, and environmental effect, alternative materials offer varied benefits and drawbacks. Here are a few examples:

- Polyester: Another synthetic polymer made from petroleum is polyester. It has many characteristics with nylon but also differs in a few areas. Polyester is less heat and abrasion resistant than nylon, but it is more water and UV radiation resistant. Additionally, polyester is less elastic and more likely to pill than nylon. Although polyester is less expensive than nylon, it requires more energy to create and is less biodegradable.

- Cotton: The cotton plant yields cotton, a natural material. It is one of the textiles that is most often used for apparel and other things. Although it is supple, breathable, and pleasant to wear, cotton also has significant disadvantages. Cotton is readily wrinkled and shrinkable, and it is not highly water- or UV-resistant. When damp, cotton is also prone to mold and mildew.Although cotton is less harmful to the environment than synthetic textiles, it still needs a lot of water and chemicals to thrive.

- Wool: This is a natural fiber that is derived from the sheep or other animal's fleece. It is among the most traditional and adaptable materials for garments and other items. Wool has certain disadvantages despite being resilient, cuddly, and warm. Wool may shrink or feel when washed and is not highly water- or UV-resistant. Additionally vulnerable to moth damage, the wool may make some individuals allergic to it or irritated. Wool is more environmentally friendly than synthetic materials, but raising animals for wool takes a lot of space and resources.

Therefore, you may wish to compare nylon with other materials and choose the one that best meets your demands based on your application and environment. To obtain a balance of qualities and performance, you may also want to think about combining several materials.

Nylon material for better sun protection

If you are looking for a way to improve the UV resistance of your nylon products, you may want to consider using EuroPlas Anti-UV Additive. This is a product from EuroPlas, a leading manufacturer and supplier of plastic additives and compounds in Vietnam.

EuroPlas Anti-UV Additive is a masterbatch that contains a blend of UV absorbers, HALS, and antioxidants that can protect your nylon products from UV degradation. It can be added to your nylon resin during the extrusion or injection molding process, and it can provide the following benefits:

- Extend the lifespan and durability of your nylon products

- Prevent discoloration, fading, and yellowing of your nylon products

- Preserve the mechanical strength, flexibility, and elasticity of your nylon products

- Reduce the maintenance and replacement costs of your nylon products

- Enhance the appearance and quality of your nylon products

EuroPlas Anti-UV Additive is compatible with various types and grades of nylon, such as nylon 6, nylon 6/6, nylon 11, nylon 12, etc. It can be used for various applications, such as textiles, carpets, ropes, nets, parachutes, tires, gears, bearings, hoses, gaskets, seals, airbags, seat belts, etc.

EuroPlas Anti-UV Additive is available in different colors and concentrations, depending on your requirements and preferences. It is easy to use and has no adverse effects on the processing or performance of your nylon products.

If you are interested in using EuroPlas Anti-UV Additive for your nylon products, please get in touch with us today for more information and a free quote. We will be happy to assist you with your needs and provide you with the best solution for your business.

EuroPlas Anti-UV Additive

EuroPlas Anti-UV Additive

10. Conclusion: Is Nylon UV resistant?

In this article, we have answered the question “Is Nylon uv resistant?” and provided some tips on how to improve UV resistance in nylon. We have learned that:

- Nylon is a synthetic polymer that has many applications in various industries.

- Is Nylon UV resistant? Nylon is not inherently UV resistant and can degrade over time when exposed to sunlight.

- UV radiation can cause discoloration, embrittlement, and cracking of nylon.

- Is Nylon UV resistant? Nylon’s UV resistance can be improved by adding UV stabilizers or protective coatings during the manufacturing process.

- Some nylon types are more resistant to UV rays than others, depending on their molecular structure and composition.

- EuroPlas Anti-UV Additive is a product from EuroPlas that can protect your nylon products from UV degradation.

Nylon is comparable to other outdoor-use fabrics like polyester, cotton, or wool.

We hope this information was interesting to you and that you learnt something new about nylon and its UV resistance. Please feel free to leave any questions or comments in the space provided below. We'd be thrilled to hear from you. I appreciate your reading.

Please get in touch with EuP for more details at europlas.com.vn/en-US/contact-us

11. FAQs

What is UV radiation?

The wavelength range of ultraviolet (UV) radiation, a kind of electromagnetic radiation, is 10–400 nanometers (nm). It may be split into UVA, UVB, and UVC categories. On the surface of the Earth, UVA radiation is most prevalent. It may enter the skin deeply, leading to early aging, wrinkles, and skin cancer. Though less prevalent than UVA, UVB is more active. It may result in skin cancer, sunburns, inflammation, and cell DNA damage. The least prevalent and most energetic form of UV light on Earth's surface is UVC. It does not reach the Earth because the ozone layer absorbs most of it. It may, however, be produced by artificial sources such as welding arcs and germicidal lights. Significant damage may be done to the skin and eyes.

How does UV radiation affect plastics?

When plastics are exposed to UV radiation, they either absorb it or produce free radicals that negatively affect the material’s mechanical properties. In addition to a reduction in mechanical strength, exposure to UV radiation can produce the following effects on plastics with low UV resistance:

- A chalk-like surface appearance

- Embrittlement and cracking on the surface

- Color changes/fading

- How can I improve the UV resistance of plastics?

- There are two main ways to improve the UV resistance of plastics:

- Choosing a plastic type that is naturally resistant to UV degradation

- Adding a UV stabilizer or protective coating during the manufacturing process

- Some examples of plastic types that are naturally resistant to UV degradation are:

- Acrylic

- Polycarbonate

- PET, or Polyethylene terephthalate

- Polyvinyl chloride (PVC)

- Some examples of UV stabilizers or protective coatings for plastics are:

- Hindered amine light stabilizers (HALS)

- Benzophenone derivatives

- Benzotriazole derivatives

- Acrylic compounds

- Epoxy compounds

Is nylon a good material for outdoor use?

Is Nylon UV resistant? Nylon is a good material for outdoor use if it has been treated with a UV stabilizer or protective coating during the manufacturing process. Otherwise, it can degrade over time when exposed to sunlight and lose its strength and flexibility.

Which nylon type is the most UV-resistant?

Among the common nylon types, nylon 6T is the most UV-resistant due to its high number of carbon atoms and aromatic ring in its monomer. It can absorb UV radiation and dissipate it as heat without affecting its molecular structure or properties.

EuroPlas Anti-UV Additive is a product from EuroPlas, a leading manufacturer and supplier of plastic additives and compounds in Vietnam. It is a masterbatch that contains a blend of UV absorbers, HALS, and antioxidants to protect your nylon products from UV degradation. It can be added to your nylon resin during the extrusion or injection molding process, and it can give your nylon products many advantages, including extending their lifespan and durability, preventing discoloration and fading, maintaining their mechanical strength and flexibility, lowering their maintenance and replacement costs, and improving their appearance and quality.