Pa12 gf20 is a type of engineering plastic that consists of polyamide 12 (pa12) compounds reinforced with 20% glass fibers. It is a high-performance material that has many advantages over pure nylon 12, such as higher strength, stiffness, thermal resistance, chemical resistance, and electrical properties. Pa12 gf20 is widely used for various applications in different industries, such as automotive, aerospace, medical, electrical, and industrial. In this article, we will introduce pa12 gf20 in detail and explain its benefits and applications.

Table of contents

- I. What is pa12 gf20?

- II. Benefits of pa12 gf20

- III. Common uses of pa12 gf20

1. Medical

2. Electrical

3. Automotive

4. Aerospace

5. Industrial

6. Consumer products

- IV. Conclusion

- V. Introduction of EuroPlas PA-GF engineering plastic compound

- VI. FAQs

I. What is pa12 gf20?

Pa12 gf20 is a thermoplastic material that belongs to the nylon family. Nylon is a synthetic polymer that can be melted and molded into different shapes and forms. Nylon has many variants, such as nylon 6, nylon 6/6, nylon 11, and nylon 12. Each variant has different characteristics and properties depending on the number and arrangement of carbon atoms in its molecular structure.

Pa12 gf20 is based on nylon 12, which has 12 carbon atoms in each repeating unit of its polymer chain. Nylon 12 is also known as polyamide 12 or pa12. It is a semi-crystalline material that has a high melting point (180°C) and a low moisture absorption rate (0.5%). It also has good resistance to chemicals, abrasion, and impact.

Pa12 gf20 is a modified version of nylon 12 that has been reinforced with 20% glass fibers by weight. Glass fibers are thin strands of glass that are added to the compounds to improve its strength, stiffness, and dimensional stability. Glass fibers also reduce the shrinkage and warping of the material during cooling and processing.

Pa12 gf20 is produced by mixing nylon 12 compounds with glass fibers in an extruder or a compounding machine. The mixture is then granulated into pellets that can be used for injection molding or other processing methods. Pa12 gf20 can also be produced by adding glass fibers directly to the injection molding machine during the molding process.

Pa gf20 Compounds

II. Benefits of pa12 gf20

Pa12 gf20 has many benefits that make it an attractive material for various applications. Some of the main benefits are:

- High strength and stiffness: Pa12 gf20 has a tensile strength of 105 MPa and a tensile modulus of 5300 MPa, which are much higher than those of pure nylon 12 (50 MPa and 1700 MPa respectively). Pa12 gf20 also has a flexural strength of 160 MPa and a flexural modulus of 5000 MPa, which are also higher than those of pure nylon 12 (80 MPa and 2000 MPa respectively). These properties make pa12 gf20 suitable for applications that require high mechanical performance and durability.

- Good thermal resistance: Pa12 gf20 has a heat deflection temperature (HDT) of 175°C at 0.45 MPa, which is higher than that of pure nylon 12 (150°C at 0.45 MPa2). This means that pa12 gf20 can withstand higher temperatures without deforming or losing its properties. Pa12 gf20 also has a low coefficient of thermal expansion (CTE) of 8 x 10-5/K, which means that it does not expand or contract significantly when exposed to temperature changes. This property makes pa12 gf20 dimensionally stable and resistant to thermal stress.

- Good chemical resistance: Pa12 gf20 has good resistance to various chemicals, such as oils, greases, fuels, solvents, acids, bases, and salts. It also has good resistance to hydrolysis, which is the degradation of the material by water or moisture. This property makes pa12 gf20 suitable for applications that involve exposure to harsh environments or fluids.

- Good electrical properties: Pa12 gf20 has good electrical properties, such as high dielectric strength (40 kV/mm), high volume resistivity (10^14 ohm.cm1), and low dielectric constant (3.5). These properties make pa12 gf20 suitable for applications that require electrical insulation or protection.

- Good processability: Pa12 gf20 can be easily processed by various methods, such as injection molding, extrusion, blow molding, thermoforming, and 3D printing. Pa12 gf20 has a low viscosity and a wide processing window, which means that it can be molded at low temperatures and pressures, and with fast cycle times. Pa12 gf20 also has good flowability and moldability, which means that it can fill complex molds and produce parts with high dimensional accuracy and surface quality.

Pa12 gf20 has many benefits

III. Common uses of pa12 gf20

Pa12 gf20 is widely used in various industries and applications, such as:

1. Medical

Pa12 gf20 is used for various medical devices and equipment, such as surgical instruments, implants, catheters, tubes, valves, connectors, housings, and casings. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good thermal resistance, good chemical resistance, good biocompatibility, good sterilizability, and good processability. Pa12 gf20 can also improve the performance and safety of the devices compared to metal or other materials.

Medical

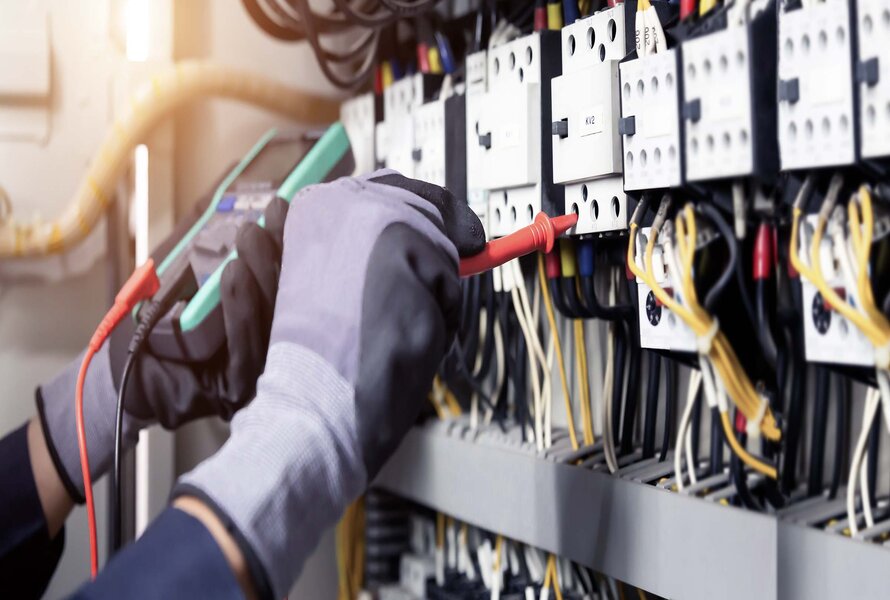

2. Electrical

Pa12 gf20 is used for various electrical and electronic parts and components, such as connectors, terminals, switches, relays, circuit breakers, fuses, sensors, actuators, transformers, coils, and housings. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good thermal resistance, good chemical resistance, good electrical properties, and good processability. Pa12 gf20 can also improve the reliability and safety of the parts compared to metal or other materials.

Electrical

3. Automotive

Pa12 gf20 is used for various automotive parts and components, such as fuel tank caps, fuel lines, connectors, sensors, valves, gears, housings, brackets, clips, and fasteners. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good thermal resistance, good chemical resistance, good electrical properties, and good processability. Pa12 gf20 can also reduce the weight and cost of the parts compared to metal or other materials.

Automotive

4. Aerospace

Pa12 gf20 is used for various aerospace parts and components, such as ducts, pipes, fittings, connectors, brackets, housings, covers, and fasteners. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good thermal resistance, good chemical resistance, good electrical properties, and good processability. Pa12 gf20 can also reduce the weight and cost of the parts compared to metal or other materials.

5. Industrial

Pa12 gf20 is used for various industrial parts and components, such as gears, bearings, bushings, rollers, pulleys, cams, levers, springs, seals, gaskets, washers, and fasteners. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good wear resistance, good friction resistance, good impact resistance, good fatigue resistance, and good processability. Pa12 gf20 can also reduce the noise and vibration of the parts compared to metal or other materials.

Industrial

6. Consumer products

Pa12 gf20 is used for various consumer products and goods, such as sports equipment, musical instruments, toys, tools, furniture, appliances, and accessories. Pa12 gf20 is preferred for these applications because of its high strength and stiffness, good aesthetic appeal, good colorability, good recyclability, and good processability. Pa12 gf20 can also enhance the functionality and durability of the products compared to metal or other materials.

Consumer products

IV. Conclusion

Pa12 gf20 is a type of engineering plastic that consists of polyamide 12 compounds reinforced with 20% glass fibers. It has excellent mechanical, thermal, chemical, and electrical properties that make it suitable for various applications in different industries. Pa12 gf20 is also easy to process by various methods, such as injection molding, extrusion, blow molding, thermoforming, and 3D printing. Pa12 gf20 is not the only type of glass-filled pa12 material available in the market. There are other types of glass-filled pa12 materials that have different percentages or types of glass fibers, such as pa12 gf23 and pa12 gf30. EuroPlas PA-GF is a brand name of engineering plastic compound that offers various grades of glass-filled pa12 materials with different percentages and types of glass fibers, as well as various additives and modifiers. EuroPlas PA-GF also offers high quality, competitive price, customization, and technical support to the customers.

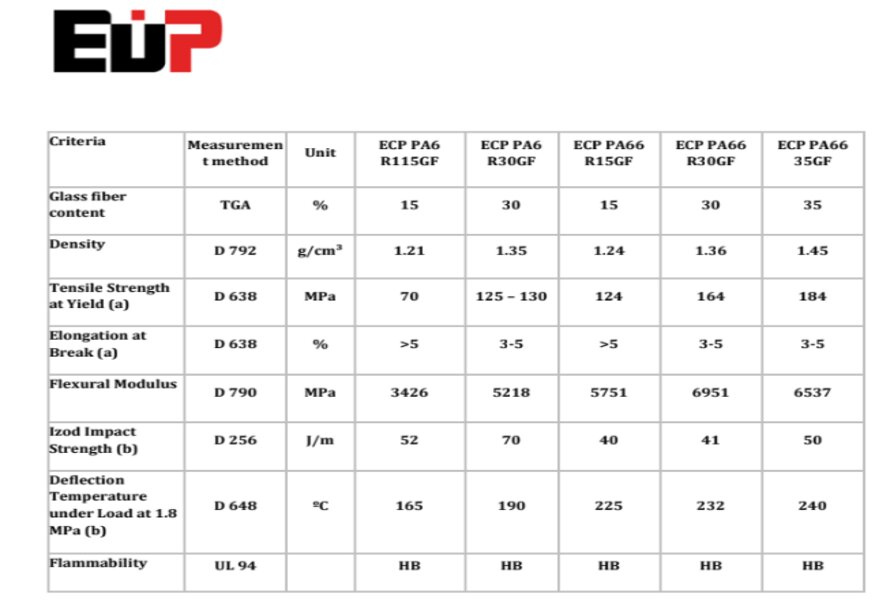

V. Introduction of EuroPlas PA-GF engineering plastic compound

EuroPlas PA-GF is a brand name of engineering plastic compound that is based on pa12 compounds reinforced with glass fibers. EuroPlas PA-GF is produced by EuroPlas Vietnam JSC, a leading manufacturer and supplier of engineering plastic compounds in Vietnam. EuroPlas PA-GF offers various grades of glass-filled pa12 materials with different percentages of glass fibers (from 10% to 50%) and different types of glass fibers (such as short glass fibers or long glass fibers). EuroPlas PA-GF also offers various additives and modifiers to enhance the properties and performance of the materials.

EuroPlas PA-GF has many advantages over other brands of glass-filled pa12 materials. Some of the advantages are:

- High quality: EuroPlas PA-GF uses high quality raw materials from reputable sources to ensure the consistency and reliability of the products. EuroPlas PA-GF also follows strict quality control procedures to ensure the compliance with international standards and customer specifications.

- Competitive price: EuroPlas PA-GF offers competitive prices compared to other brands of glass-filled pa12 materials in the market. EuroPlas PA-GF also offers flexible payment terms and delivery options to meet the needs of different customers.

- Customization: EuroPlas PA-GF can customize the products according to the specific requirements and preferences of the customers. EuroPlas PA-GF can adjust the percentage and type of glass fibers, as well as add other additives and modifiers to achieve the desired properties and performance of the products.

- Technical support: EuroPlas PA-GF provides technical support to the customers before, during, and after the purchase of the products. EuroPlas PA-GF can provide technical data sheets, material safety data sheets, certificates of analysis, test reports, and other documents to help the customers understand and use the products properly. EuroPlas PA-GF can also provide technical advice, troubleshooting, and training to help the customers optimize the processing and performance of the products.

EuroPlas PA-GF engineering plastic compound

VI. FAQs

Here are some frequently asked questions about pa12 gf20 and glass-filled pa12 materials:

What is the difference between pa12 gf20 and pa66 gf30?

Pa12 gf20 and pa66 gf30 are both types of glass-filled nylon materials, but they have different base compounds and different percentages of glass fibers. Pa12 gf20 is based on nylon 12 compounds with 20% glass fibers, while pa66 gf30 is based on nylon 6/6 compounds with 30% glass fibers. Pa12 gf20 has higher thermal resistance, lower moisture absorption, and better chemical resistance than pa66 gf30. Pa66 gf30 has higher strength and stiffness than pa12 gf20.

How can I tell if a part is made of pa12 gf20 or another type of plastic?

One way to tell if a part is made of pa12 gf20 or another type of plastic is to perform a burn test. A burn test involves heating a small piece of the part with a flame and observing its behavior. Pa12 gf20 will melt and drip when heated, and produce a blue flame with a faint odor. Other types of plastics may have different melting points, flame colors, or odors.

How can I recycle pa12 gf20 parts?

Pa12 gf20 parts can be recycled by grinding them into flakes or pellets and reusing them for new parts or products. However, recycling may affect the properties and performance of the material due to degradation or contamination. Therefore, recycling should be done with caution and quality control.

Where can I buy pa12 gf20 or other types of glass-filled pa12 materials?

You can buy pa12 gf20 or other types of glass-filled pa12 materials from EuroPlas Vietnam JSC, a leading manufacturer and supplier of engineering plastic compounds in Vietnam. You can visit their website at europlas.com.vn or contact them at europlas.com.vn/en-us/contact-us for more information.

How can I learn more about pa12 gf20 or other types of glass-filled pa12 materials?

You can learn more about pa12 gf20 or other types of glass-filled pa12 materials by reading online articles, books, journals, or blogs on the topic. You can also watch videos, podcasts, or webinars on the topic. You can also attend seminars, workshops, or courses on the topic.

What are some examples of products or parts that are made of pa12 gf20 or other types of glass-filled pa12 materials?

Some examples of products or parts that are made of pa12 gf20 or other types of glass-filled pa12 materials are: Fuel tank caps, fuel lines, connectors, sensors. Valves, Gears, Housings, Brackets, Clips, Fasteners, Ducts, Pipes, Fittings, Surgical instruments, Implants, Catheters, Tubes, Switches, Relays, Circuit breakers, Fuses, Actuators, Transformers, Coils, Bearings, Bushings, Rollers, Pulleys, Cams, Levers, Springs, Seals, Gaskets, Washers, Sports equipment, Musical instruments, Toys, Tools, Furniture, Appliances, Accessories.