1. Overview Of Heat Resistant Material In 3D Printing

Heat resistant materials in 3D printing are specially formulated substances that can withstand high temperatures without losing their structural integrity or functionally. Heat resistant materials are crucial for applications in industries like aerospace, automotive, and electronics, where components are often exposed to extreme heat.

2. Top 7 Heat Resistant Materials For 3D Printing

Heat resistant materials are vital in 3D printing, especially for applications that require components to endure high temperatures. Here are seven of the best materials known for their heat resistance:

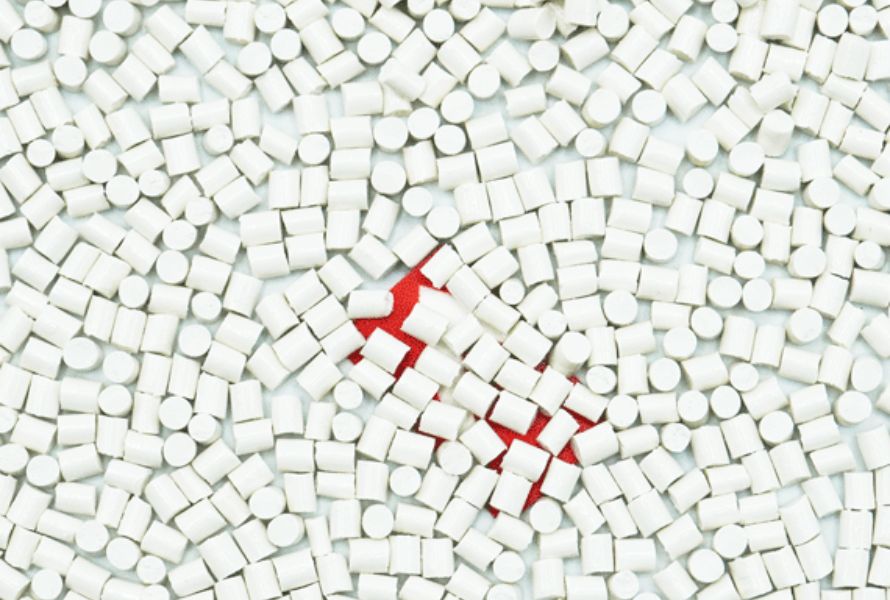

2.1. ABS

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic polymer in 3D printing, known for its exceptional mechanical properties. This material offers excellent dimensional stability and high impact resistance, making it suitable for functional prototypes and end-use parts. Its ability to withstand elevated temperatures without significant deformation enhances its appeal for engineering applications. Moreover, ABS's balanced hardness and gloss provide aesthetically pleasing finishes, while its resistance to aqueous acids and oils ensures durability in various environments.

2.2 PC

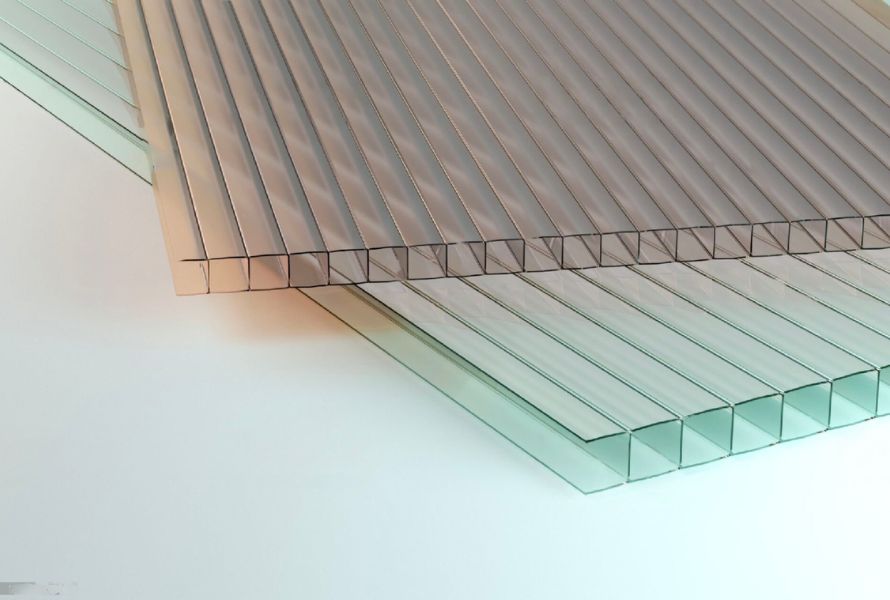

PC, or Polycarbonate, is known for its high tensile strength and temperature resistance. While 3D printing with polycarbonate can be challenging due to thermal expansion, manufacturers have developed polycarbonate composites to improve printability.

Some heat-resistant polycarbonate composite filaments can achieve heat deflection temperatures (HDT) of up to 100°C to 140°C at 0.45MPa. These filaments often incorporate additional components such as carbon fibers or glass fibers, which enhance strength and minimize warping during the printing process. Moreover, polycarbonate boasts excellent impact resistance, making it an ideal choice for applications requiring high durability and thermal stability.

2.3. PEEK

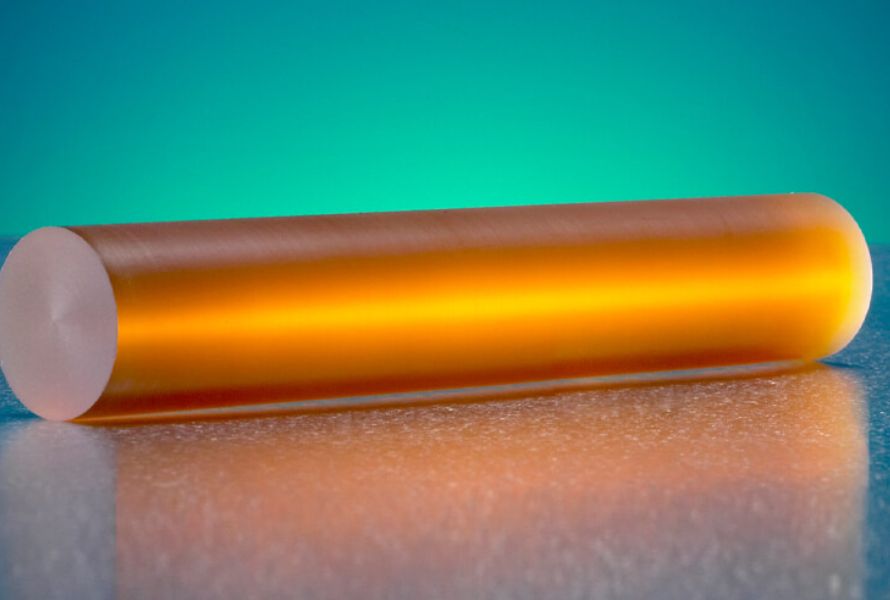

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic renowned for its exceptional heat resistance and mechanical properties. This advanced material is capable of maintaining its stiffness and dimensional stability at elevated temperatures, making it suitable for continuous use at temperatures up to 170°C.

One of the standout features of PEEK is its remarkable resistance to thermal degradation and chemical attack. This allows it to perform reliably in demanding environments, such as those found in aerospace, oil and gas, and semiconductor industries. Additionally, PEEK can be processed using various techniques, including injection molding and 3D printing, which enhances its versatility. The ability to create complex geometries and customized parts makes PEEK a preferred choice for engineers and designers looking to innovate in high-performance applications.

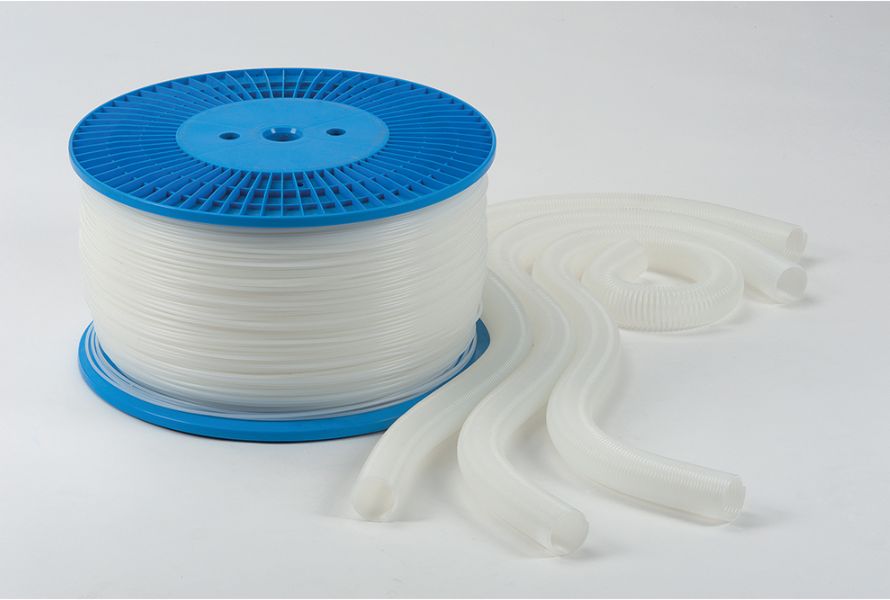

2.4. PP

Polypropylene (PP) is a lightweight and durable thermoplastic polymer that stands out as one of the prominent heat resistant materials in modern engineering. Renowned for its exceptional resistance to a broad spectrum of chemicals, including solvents, bases, and acids, PP exhibits a high melting point that allows it to maintain structural integrity even under elevated temperatures. Its inherent flexibility, combined with excellent electrical insulation properties, makes it ideal for applications requiring repeated bending. Additionally, PP demonstrates impressive fatigue resistance, ensuring longevity in demanding environments.

2.5. ULTEM

ULTEM, or polyetherimide (PEI), is increasingly recognized in the realm of 3D printing for its exceptional performance characteristics. This high-performance engineering thermoplastic is valued for its high mechanical strength, broad chemical resistance, and excellent thermal stability, making it suitable for demanding applications.

ULTEM maintains its integrity over a wide temperature range, withstanding continuous operating temperatures up to 180°C. Its inherent flame retardant properties and low smoke generation further enhance its appeal in safety-critical environments.

2.6. Polyamide (PA)

Polyamide (PA), commonly referred to as nylon, is a thermoplastic renowned for its excellent mechanical properties and versatility in 3D printing applications. As a member of the heat resistant materials category, PA exhibits remarkable stability and resilience, maintaining its dimensional integrity at temperatures up to 163 °C for thicker parts. This makes it particularly suitable for end-use components that must endure challenging environment conditions.

2.7. PEKK

Polyetherketoneketone (PEKK) is a remarkable addition to the family of heat resistant materials used in 3D printing, available in both amorphous and semi-crystalline forms. The semi-crystalline variant, PEKK-SC, offers superior heat resistance compared to its amorphous counterpart, PEKK-A, making it ideal for applications requiring enhanced mechanical properties.

However, PEKK-SC presents challenges in the printing process due to its rapid crystallization. In contrast, PEKK-A is easier to print but has lower temperature resistance, meeting only UL94-V0 standards. Notably, PEKK is easier to process than PEEK and does not emit toxic gases during printing, with lower extrusion temperatures.

3. Conclusion

In conclusion, these seven heat resistant materials offer a range of options for 3D printing applications that require thermal stability. From the widely used ABS to high-performance polymers like PEEK and ULTEM, manufacturers can choose the most suitable materials based on their specific temperature requirements and end-use applications.

4. Finding The Best 3D Printing Solutions In EuroPlas

EuroPlas is recognized as the world's leading manufacturer of filler masterbatch, specializing in providing cost-effective plastic materials. With a strong commitment to quality and innovation, EuroPlas offers a diverse range of products, including filler masterbatch, color masterbatch, additives, engineering plastics, and bioplastics.

EuroPlas also supplies a range of 3D printing products made from various materials, including:

- PC (Polycarbonate) Compounds: EuroPlas offers flame-retardant PC compounds compliant with UL94 standards (5VA, 5VB, V0, V1, V2). Ideal for high-safety applications like mobile chargers and electronics, these compounds provide excellent fire resistance and durability.

- PP talc (Polypropylene) Compounds: EuroPlas offers a premium PP talc compound containing 20% talc powder, ideal for manufacturing motorcycle and automotive parts that demand excellent durability and high heat resistance (up to 130°C). This versatile material can be easily customized and processed directly, ensuring efficiency in production.

- PA (Polyamide) Compounds: Featuring PA6 and PA66 blends, these high-performance compounds deliver superior mechanical strength and durability. With 15 years of expertise, EuroPlas provides stable, high-quality materials for precise end products.

- ABS flame retardant Compound: EuroPlas's ABS flame retardant compound is a specialized thermoplastic that combines ABS resin with halogen-free flame retardant additives, enhancing its fire resistance according to UL94 standards. Available in various fire resistance levels (V0, V1, and V2), this material is designed to slow or prevent the spread of flames, making it ideal for applications where fire safety is paramount.

Discover heat resistant materials of the highest quality at EuroPlas! Visit our website to learn about our flame-retardant PC, PP, and PA compounds that enhance the durability and safety of your products.

If you would like to buy our products or have any questions, please visit the Contact Us page of EuroPlas. We are always ready to assist you and provide the necessary information to meet your needs.

Learn more: