Bakelite plastic is a very efficient electrical insulating material. This thermosetting polymer is made by mixing formaldehyde and phenol and is a great option for high-performance products that need crucial electrical insulation. Its non-conductive barrier and remarkable dielectric strength make it suitable for many applications in the electrical industry.

This in-depth blog will provide more interesting details about this material. Follow along!

Read more: Bakelite: The vintage plastic that sparked a revolution

1. Key Applications of Bakelite in Electrical Industry

Bakelite plastic is used in many electrical products that are familiar to people. Its key applications include:

- Switches and relays: Bakelite is a common material used in the manufacture of switches and relays because it can insulate electrical connections. These devices are safer and last longer thanks to their durability and stiffness, which can tolerate mechanical pressures, and their insulating qualities, which guard against unintentional short circuits.

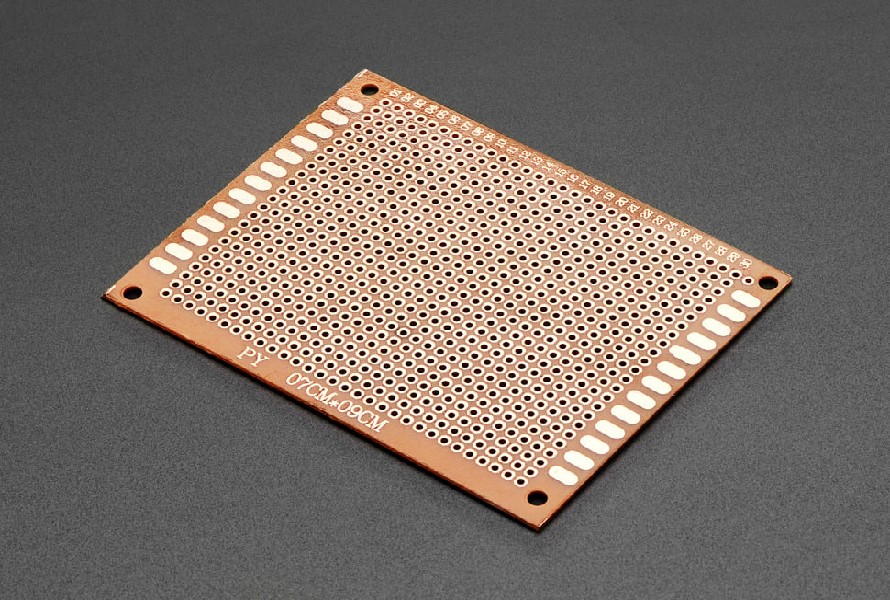

- Circuit boards: Bakelite plastic provides a sturdy, non-conductive surface on which to mount electronic components. Thus, it guarantees safe device operation under challenging circumstances. Its great mechanical strength and heat resistance ensure longevity and dependability.

Bakelite plastic circuit boards

- Protective covers and insulating barriers: Bakelite is used to create protective coverings and insulating barriers for electrical components to provide extra insulation and avoid unintentional contact. The durability and resilience to environmental influences of the material allow the components to work effectively over time. For example, transformers frequently employ bakelite casings to protect internal parts like windings and tap changer mechanisms from environmental elements including dust, moisture, and mechanical damage. In power grids and industrial systems, the strong heat resistance of bakelite plastic guarantees integrity even under heavy loads.

- Transformers and capacitors: Because of its great dielectric strength, Bakelite is an essential insulating material for transformers and capacitors, enabling them to withstand high voltages without breaking down. Since it helps drain heat, it also keeps transformers efficient and helps avoid electrical arcing.

- Motor components: As a vital material in the electrical and electronics sector, Bakelite is utilized in electric motors for parts like insulating plates and commutator segments. Because of its exceptional mechanical strength, thermal stability, and electrical insulation, motor components are guaranteed to be reliable and effective for the duration of their service life.

2. Advantages of Using Bakelite in Electrical Applications

Bakelite plastic details

As an indispensable material in the electrical industry, bakelite plastic offers the following benefits:

- Durable performance: For long-term use in demanding electrical equipment, Bakelite is the perfect material since it is resilient to heat fluctuations and mechanical stress. It is essential for high-traffic situations like industrial automation or power grids where components must function reliably for years. Its stiff construction helps shield sensitive components from environmental exposure.

- Safety: The electrical insulating properties of bakelite plastic keep electricity from departing its route, lowering the chance of short circuits and fires. It’s especially important in high-voltage systems, where failure might have disastrous results. Transmission lines use bakelite insulators to protect against arcing, short circuits, and leaks. It guarantees that electrical systems remain safe and functional even under various circumstances.

- Customization: Bakelite plastic can be customized to meet certain project needs. For example, Bakelite insulators can be made to comply with particular voltage and temperature requirements.

- Cost-effectiveness: In the long term, Bakelite is a cost-effective alternative because of its long-lasting sturdiness and low maintenance needs, even if its initial costs can be high. Breakdowns, downtime, and repair expenses are decreased when Bakelite parts are customized to meet system requirements.

3. Challenges and Modern Alternatives

Despite its advantages, like other materials, bakelite plastic also has some disadvantages.

- Brittleness: Once the plastic gets old, it’s more likely to be cracked if mishandled. Thus, gentle care is always a priority.

- Discoloration: When staying under sunlight, bakelite components can turn yellow due to the effects of UV light and age.

Old bakelite electrical sockets

- Environmental impact: The environmental effect of Bakelite has drawn criticism. Its energy-intensive and greenhouse gas-releasing production method uses petroleum and formaldehyde. Bakelite plastic is difficult to recycle or reuse due to its infusibility. Microorganisms cannot decompose because of their phenol-formaldehyde polymer chains, which persist for millennia after disposal.

- Modern alternatives: Other thermoplastics like polypropylene and polyethylene terephthalate (PET) have replaced Bakelite in some fields. PET offers reasonably priced clarity and shatter resistance, making it perfect for food and drink containers, while polypropylene gives flexibility, heat resistance, and durability. When produced according to the best methods, both materials are recyclable and emit few emissions.

Bakelite cannot compete with the customized thermal stability, impact resistance, and recycling simplicity of modern polymers. Fiberglass and other supplemental materials can improve strength and durability even more. Moreover, PLA bioplastics provide a sustainable substitute for petrochemicals as they are made from renewable plant sources. By composting, these bioplastics naturally break down and cut down on toxic emissions. Thus, bakelite plastic is facing the challenge of being replaced in the market.

4. Conclusion

Bakelite plastic is a go-to choice in the electrical industry. Its chemical structure offers unparalleled dielectric strength and superior thermal stability, making it subtle for electrical insulation and high-temperature applications.

Though it has some disadvantages and the competition in the material market has become more cruel, bakelite plastic is still a popular and worth-considering option for many manufacturers.

5. About EuroPlas

EuroPlas - a reliable supplier

As one of the top filler masterbatch manufacturers, EuroPlas provides customized plastic material solutions for businesses to boost their market competitiveness. With a dedication to quality and innovation, we offer products that meet high requirements of efficiency, durability, and quality, such as engineering plastic compounds, plastic additives, and bioplastics.

Contact us right now for our consultation!