This article will provide information about PC and PBT plastics including properties, applications and their compounds.

Related:

1. About PC plastic

1.1. Definition

PC plastic is an amorphous thermoplastic with high thermal, optical and mechanical properties. The combination of physical properties makes it one of the most versatile thermoplastics, widely used in industries such as electrical, electronic, automotive, construction, etc.

PC plastic is an amorphous thermoplastic with high thermal, optical and mechanical properties.

1.2. Properties of PC plastic

- High impact resistance

- Good durability

- High stability and dimensional accuracy

- Wide operating range: from low temperature -40oC to 120oC

- Excellent transparency and purity

1.3. Applications of PC plastic

- Household items: such as camera covers, vacuum cleaners, phone cases, power tools, sockets, lamp tails, etc.

- Water bottles, milk bottles, light boxes, sunglasses

- Exposure sheet

- Automotive field: car dashboard, decorative parts in cars, headlights, fog lights...

Applications of PC plastic

1.4. PC compound

PC compound is a product developed based on PC resin mixed with various additives and reinforcements such as beads or glass fibers, anti-static additives, etc., depending on different formulas to meet specific requirements of each final plastic product.

PC–GF compound ratio: 10-30%

PC-GF is a PC compound with fiberglass. Its main characteristics are:

- Increased surface hardness

- Good impact resistance

- Good thermal properties

PC-GF is applied in the production of computer components, office gears, household electrical components, camera components.

PC-GF is applied in the production

Technical properties

|

Feature

|

Method

|

Units

|

PC 20GF

|

PC 30GF

|

|

Melt Flow Rate (300°C/1.2kg)

|

D 1238

|

g/10 min

|

91.98

|

136.56

|

|

Density

|

D 792

|

g/cm³

|

1.070

|

1.157

|

|

Tensile Strength at Break (a)

|

D 638

|

MPa

|

23.78

|

46.16

|

|

Elongation at Break (a)

|

D 638

|

%

|

3 - 5

|

3 - 5

|

|

Flexural Modulus

|

D 790

|

MPa

|

4442.8

|

6343.8

|

|

Izod Impact Strength (b)

|

D 256

|

J/m

|

25.233

|

35.368

|

|

Deflection Temperature

under Load at 1.8 MPa (b)

|

D 648

|

ºC

|

124.2

|

124.7

|

|

Flammability

|

UL 94

|

|

HB

|

HB

|

|

Hardness RockWell

|

|

HRR

|

116

|

105

|

Compound PC–FR

PC-FR is a PC compound with halogen flame retardant additives. Depending on the needs of customers, EuP provides compound products with fire resistance levels according to UL94 standards: 5VA, 5VB, V0, V1, V2. PC-FR compound is widely used in the production of electrical and electronic parts, finished products requiring fire resistance.

Technical properties

|

Feature

|

Method

|

Units

|

ECP PC R1001

|

ECP PC R1001V0

|

|

Melt Flow Rate (300°C/1.2kg)

|

D 1238

|

g/10 min

|

34

|

34

|

|

Density

|

D 792

|

g/cm³

|

1.22

|

1.21

|

|

Tensile Strength at Break (a)

|

D 638

|

MPa

|

60

|

61

|

|

Elongation at Break (a)

|

D 638

|

%

|

>5

|

>5

|

|

Flexural Modulus

|

D 790

|

MPa

|

2256

|

2270

|

|

Izod Impact Strength (b)

|

D 256

|

J/m

|

103

|

105

|

|

Deflection Temperature

under Load at 1.8 MPa (b)

|

D 648

|

ºC

|

118

|

120

|

|

Flammability

|

UL 94

|

|

5VA

|

V0

|

2. About PBT plastic

2.1. Definition of PBT plastic

Polybutylene terephthalate (PBT) is a thermoplastic engineering polymer resin used as an insulator in the electrical and electronic industries. It is a semi-finished plastic crystalline polymer.

2.2. Properties of PBT plastic

PBT is solvent resistant, stretches little during forming, is heat resistant up to 150°C (or 200°C with fiberglass reinforcement) and can be reinforced with flame retardants to make it non-combustible.

2.3. Applications of PBT plastic

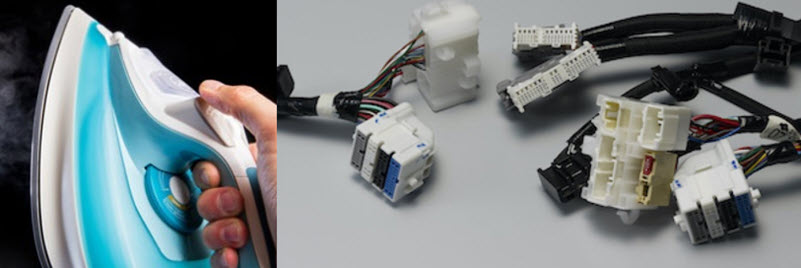

- Polybutylene terephthalate is widely used in electrical engineering, construction, the manufacture of car sockets and household appliances such as showers or irons.

- It is also made into toothbrushes, false eyelashes, and is used in the keycaps of some high-end computer keyboards because the texture is resistant to abrasion and discoloration from UV radiation.

- Widely used in swimming pool equipment, due to its strong resistance to water and chlorine.

- PBT has high fire resistance and hardness, so it is widely used in the production of plastic parts for cars, motorcycles, batteries, radiator fans, and household electrical appliances.

Applications of PBT plastic

2.4. PBT compound

PBT plastic compound is an engineering plastic based on PBT primary plastic, mixed with many different additives and reinforcements such as glass fiber, color, flame retardant additives according to different formulas to meet the properties. specific characteristics of each plastic product.

European Plastic Company provides the main PBT compound product lines which are glass fiber PBT compound (PBT–GF), V0 flame retardant PBT compound (PBT–FR). The material is applied in electrical engineering, construction, industry, socket manufacturing, household appliances.

PBT compound

PBT GF-FR compound

PBT group GF-FR is a compound product made from PBT resin with glass fiber and flame retardant additives. Depending on customer needs, EuP provides compound codes with glass fiber ratio and fire resistance level according to UL94 standards: 5VA, 5VB, V0, V1, V2 as appropriate. With fire resistance and high hardness, GF-FR group PBT is widely used in the manufacture of parts for cars, motorcycles, battery turbines, radiator fans, and household electrical appliances.

Technical properties

|

Feature

|

Method

|

Units

|

ECP PBT R15GFV0

|

ECP PBT R930GFV0

|

|

Glass fiber content

|

TAG

|

%

|

15

|

30

|

|

Density

|

D 792

|

g/cm³

|

1.48

|

1.56

|

|

Tensile Strength at Yield (a)

|

D 638

|

MPa

|

103

|

110

|

|

Elongation at Break (a)

|

D 638

|

MPa

|

2-3

|

2-3

|

|

Flexural Modulus

|

D 790

|

MPa

|

5840

|

8000

|

|

Izod Impact Strength (b)

|

D 256

|

kJ/m2

|

7

|

11

|

|

Deflection Temperature

under Load at 1.8 MPa (b)

|

D 648

|

ºC

|

180

|

190

|

|

Flammability

|

UL 94

|

|

V0

|

V0

|

If you are looking for top-quality PC engineering plastic compounds, contact EuroPlas today. Our experienced team is ready to discuss your requirements and provide customized solutions tailored to your specific needs.