To manufacturers, choosing the suitable material for your product can make a significant impact on its performance, cost, and sustainability. Two popular plastics widely used in the industry are polyvinyl chloride (PVC) and polycarbonate (PC). Both materials have unique properties, strengths, and limitations that make them suitable for different applications. In this article, we will compare the differences between polyvinyl chloride vs polycarbonate to help manufacturers make an informed decision.

1. What is PVC?

Polyvinyl chloride, or PVC, is a synthetic plastic polymer made from vinyl chloride monomer. PVC is the third most manufactured synthetic plastic polymer in the world. Each year, 40 million tons of PVC are produced.

Because of being a thermoplastic, PVC can be melted and molded into various shapes and forms. This polymer is brittle solid, and white in its pure form. PVC is available in two main types: flexible (Plasticized PVC) and rigid (Unplasticized PVC). Here are the properties of the two forms of PVC:

| Flexible PVC |

Rigid PVC |

- Low price

- Excellent vapor barrier and rigidity

- Good electrical insulation

- Good thermal stability

- Good heat resistance

- Good chemical resistance

|

- Low price

- High-impact strength and flexibility

- Good chemicals resistance

- Good UV light Resistance

- Good electrical insulation

- Easy processing

|

To improve PVC's lack of physical strength, manufacturers have added many plastic additives to the original mixture. Several of the properties of the products can be influenced by or determined by additives, such as flame retardants, processing-aid additives, plasticizers, and anti-UV additives.

The ability to be compatible with a wide variety of additives is also a strength of this material. This feature gives PVC many applications in the construction, automotive, electronics, and healthcare industries.

2. What is PC?

Polycarbonate (PC) is a rigid, durable plastic material made from bisphenol A (BPA) and phosgene. As a thermoplastic, polycarbonate melts when exposed to high temperatures, yet it can be cooled again without suffering much from quality loss.

Polycarbonate offers numerous benefits; therefore, it is widely used in many industries. Polycarbonate has identical light transmission capabilities to glass, providing an advantage over glass since it performs optically similarly but is substantially more lightweight and durable.

A polycarbonate sheet is 250 times more durable and shatter-resistant than a pane of glass. As a result, polycarbonate is an ideal choice for making robust and long-lasting consumer goods, protecting against harsh weather, flying debris, and vandalism.

Here are some of its properties including:

- High impact resistance

- High UV stability and clarity

- High flame retardant

- Good impact strength

- Good dimensional stability

- Good electrical properties

- Lightweight

Polycarbonate polymers are used to make a range of materials, and they are especially suitable when impact resistance or transparency is required. Some of the common applications of PC are:

- Consumer goods

- Electrical & Electronics

- Medical devices

- Sheets and films extrusion

- Automotive components

- Protective gear

- Injection molding

- Digital Disks (CDs, DVDs, and Blu-ray)

- Exterior lighting fixtures

3. The differences between PVC and Polycarbonate

PVC and polycarbonate are known for their strength, durability, and versatility. However, they have distinct differences that make them suitable for different applications. We will explore the main differences between polycarbonate vs PVC below, including their properties, recyclability and sustainability, cost, and application.

| |

Polyvinyl chloride (PVC) |

Polycarbonate (PC) |

| Formation |

Formed from the polymerization of vinyl chloride |

Formed from the reaction between phosgene and Bisphenol A |

| Molecular formula |

(C2H3Cl)n |

C16H16O4

|

Monomer

|

Vinyl chloride

|

Bisphenol A and Phosgene

|

Molar mass

|

62.50 g/mol |

272.29 g/mol |

Functional groups

|

Chloride groups

|

Carbonate groups

|

| Aromatic Rings |

No |

Yes |

Melting point

|

Around 212°C

|

Around 225°C

|

Glass transition temperature

|

81°C

|

147°C |

3.1. Properties

Regarding chemical composition, PVC is a synthetic plastic made from vinyl chloride monomer through polymerization. It comprises 57% chlorine and 43% carbon and hydrogen atoms. PC, on the other hand, is synthetically made from bisphenol A and phosgene. It is composed of a carbonate group.

The chemical formula determines the main differences in PVC and PC properties. PVC is a rigid, brittle plastic with low impact resistance, tensile strength, and flexibility. PC is a tough, durable plastic with high impact resistance, high tensile strength, and good flexibility.

To compare PVC vs polycarbonate melting temperature, PVC has a low melting point of around 212°C and a low glass transition temperature of around 81°C. It is also a poor thermal conductor, making it suitable for insulation applications. Polycarbonate has a higher melting point of about 225°C and a higher glass transition temperature of around 147°C. It is also a better thermal conductor than PVC.

When it comes to chemical resistance, PVC has good resistance to acids, bases, salts, fats, and alcohol in general. It is not resistant to organic solvents like chlorinated hydrocarbons, ketones, and cyclic ethers. On the contrary, polycarbonate presents excellent chemical resistance to various compounds such as acids, oxidizing agents, neutral and acid salt solutions, oils, detergents, saturated, aliphatic and cyclo aliphatic hydrocarbons, and alcohols.

3.2. Recyclability and sustainability

The main component of polycarbonate is hydrocarbon-based raw materials, which makes it fully recyclable. Polycarbonate is often recycled by sorting, shredding, and washing it before granulating it for reuse. This process requires some sortings to reduce impurities and color contamination.

Much the same as PC, Polyvinyl Chloride is also 100% recyclable and quickly sorted for high purity in both rigid and flexible forms. This material can be recycled mechanically (grinding, remelting, and remolding process) or chemically (converting the waste into reusable components by pyrolysis or hydrolysis).

3.3. Cost

Whereas salt and oil are the primary raw ingredients for PVC, polycarbonates are produced through a series of stages that transform hydrocarbon-based raw resources (derived from petroleum, natural gas, or coal) into plastics. As a consequence, PVC and polycarbonate prices are significantly influenced by crude oil prices.

Polycarbonate is a high-cost material because of its high specialization and complex manufacturing. It costs roughly $2.80 per kilogram. Even its recycled material is expensive, up to $1.60 per kilogram.

PVC is widely accessible from various suppliers for being a commodity substance having interchangeable sources (with established specifications). The price of raw UPVC granules is $0.80-2.00 per kilogram.

4. Application

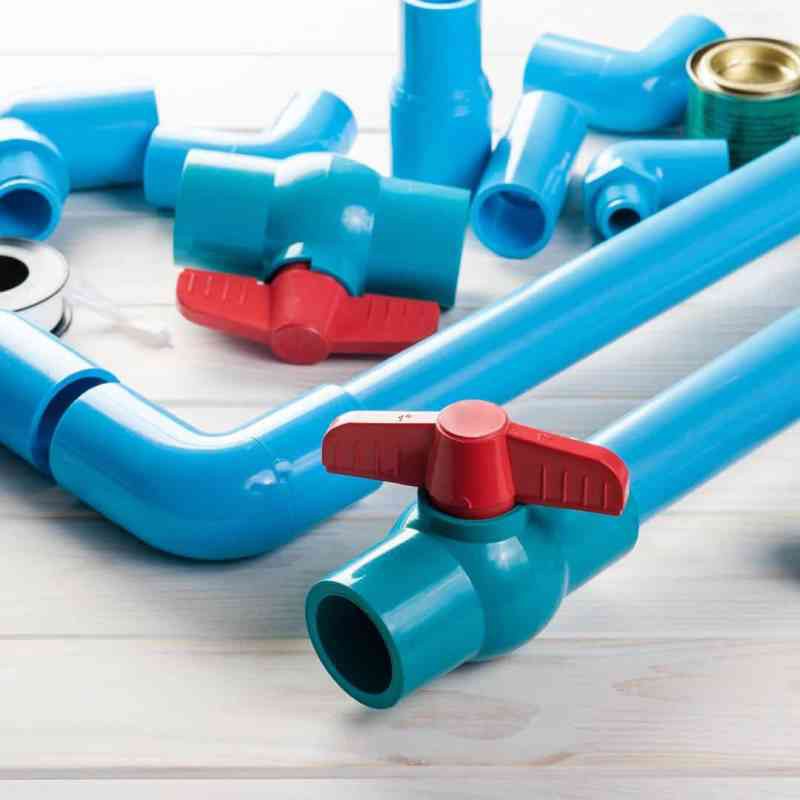

Thanks to its excellent properties and cost-effectiveness, PVC is one of the most widely used materials. There are numerous usages of PVC, such as:

- Construction: pipes, window frames, roof lining, greenhouses

- Interiors: curtain rails, wall coverings, hosepipes

- Packaging: bottles, punnets

- Safety Equipment: gloves, gumboots, traffic cones

- Electricity and electronics components: cable insulation, conduit

Polycarbonate is the ideal material for many applications that require high impact strength, high heat resistance, and glass-like surface, including:

- Household appliances: refrigerators, washing machines, air conditioners, food mixers

- Automobile: car’s interior and exterior

- Construction: agricultural houses, security windows, facades, skylights

- Medical: surgical instruments, blood reservoirs, drug delivery systems

- Food storage: microwave-safe containers

- Telecom: pager parts, phone cases

This article has shown the significant differences between polyvinyl chloride vs polycarbonate. Those two materials have unique properties and advantages that make them suitable for different applications. The choice between PVC and PC lies in the specific needs and requirements of intended applications and a careful evaluation of the benefits and limitations of each material.