Engineering plastic compound has gradually become a potential alternative to traditional virgin resin. According to Grand View Research, the engineering plastic compound market in Southeast Asia reached 2,125.5 kilotons in 2018. Along with the surge across the fields of automation, packaging, consumer goods, machinery industry,... the market value of engineering plastic compound is predicted to reach USD 6.7 billion by 2026. In particular, the number of compound consumed in the industrial machine sector can reach 188.8 kilotons with 384 million USD in revenue by 2026.

1. Engineering plastic compound - Composition and outstanding features

Engineering plastic compound is a combination of fossil resin, specific reinforcements and suitable additives. Some types of fossil resins commonly used in compounds are ABS, PP, PC, PA6, PA66,... Based on the characteristics of each end-product, specific reinforcements and additives will be mixed with the base resin to create engineering plastic compound that meet standard requirements. That also means manufacturer can directly put the compound into processing phase without going through any other mixing stages, thus improving productivity and optimizing production costs.

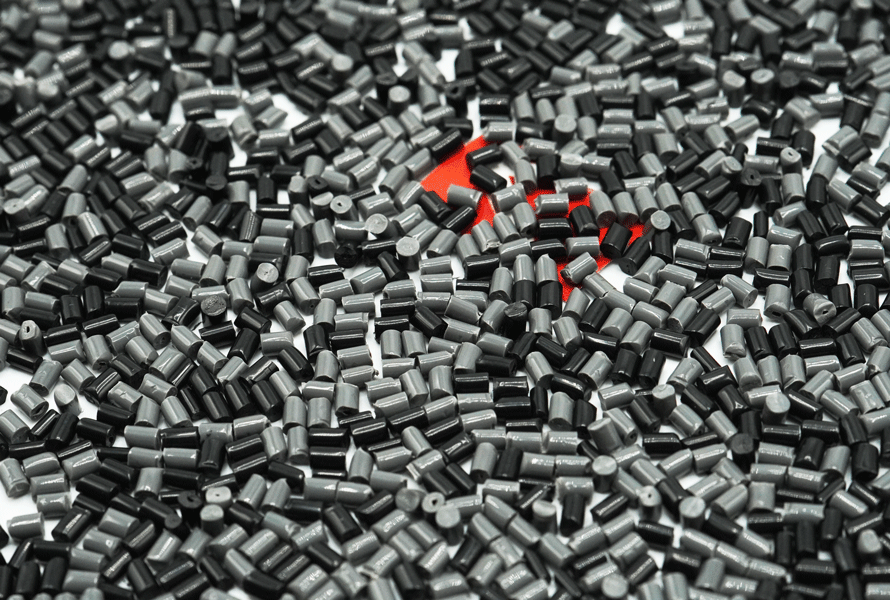

Engineering plastic compound

2. Common types of engineering plastic compounds for technical components

Based on the characteristics of end products, manufacturer can choose different types of engineering plastic compounds. These below are 5 common ones that are highly-recommended for machinery processing.

Compound POM

POM engineering plastic is also known by the common name acetal. The material is made from POM primary plastic, mixed with many different additives and reinforcements, or blended with other plastic bases according to suitable formulas to meet the specific characteristics of each finished product.

POM engineering plastic compound

Compound POM is commonly used in the production of mechanical parts such as bearings, nuts, plastic joints,... These are important components of water pumps, drills, fans, air compressors, machines, industrial processing, automobile assembly,... that helps to maintain the movement of machines and engines by reducing friction in motion. The application of POM compound in mechanical parts provides end-products with high hardness, good wear resistance and bearing capacity, stable dimensions, low deformation in processing, temperature resistance, beautifully glossy surface,…, thus improving the efficiency and durability of end-products.

Compound PA6/PA66

PA6/PA66 compound is a blend of PA6/PA66 fossil resin and appropriate reinforcements/additives. This material is commonly used in automotive and motocycle industry, such as gears, roller bearings (bearings), gears of office equipment, gear assemblies, carburetors, exhaust gas control valves, fuel tank caps,…

PA6/PA66 engineering plastic compound

With outstanding advantages such as high hardness, dimensional stability, a low level of shrinkage, and abrasion resistance, PA6/PA66 engineering plastic compound creates end products with great precision and high mechanical strength, while achieving better usage and durability.

Compound PC

Compound PC is highly recommended thanks to its great mechanical strength, good bearing capacity, wear resistance and high transparency. Hence, when combining with other components, such as reinforcements and additives, compound PC becomes an ideal choice for mechanical components, such as electric meters, camera parts, electronic components,… This material helps to limit shrinkage and deformation during the machining process, thereby creating a end-products with high sharpness. Also, PC compound does not sustain flame, which ensures the safety for users.

PC engineering plastic compound

Compound PBT

PBT compound is a type of engineering plastic compound based on PBT resin, mixed with appropriate reinforcements and additives to meet specific technical requirements of end-products. With its fire resistance and high rigidity, PBT compound is widely used in parts of cars, motorcycles, turbines, radiator fans, and household electrical appliances.

PBT engineering plastic compound

Compound PP

PP compound is amongst the largest-consumed engineering plastic compound worldwide. According to Grand View Research, the volume of PP compound consumption is about 658.1 kilotons in 2018 and is expected to reach 1,112.6 kilotons by 2026. The automotive industry is the largest contributor to the PP engineering plastic compound consumption, thanks to the good impact resistance and flexibility of this material. Some common applications include automotive and motorcycle components, fuel tank cap, household electrical and electronic components,...

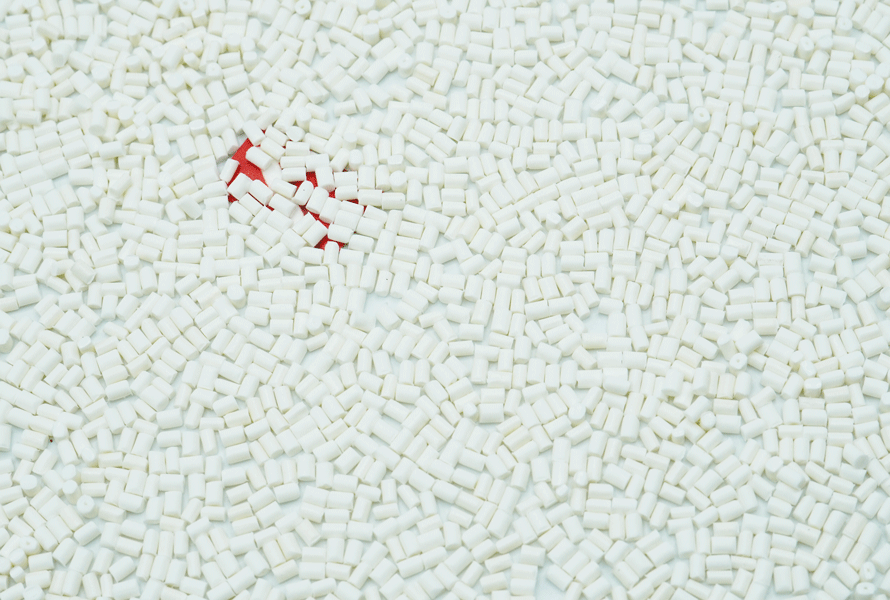

PP engineering plastic compound

Thanks to its outstanding technical advantages and tremendous applications, engineering plastic compound is predicted to become a new material trend, thus helping manufacturers improve product quality and optimize processing costs.

3. EuroPlas engineering plastic compound

In Vietnam, EuroPlas is one of the pioneers in research and production of engineering plastic compound with modern production lines and a system of international technical standards. EuroPlas compound is customized based on the characteristics of the end-products, thus helping customers improve end-products’ quality as well as reducing processing time and increasing labor productivity.

For detailed information and consultation, please contact HERE!