What material is Polyurethane resin? What are the advantages and materials of PU plastic? This is a question that many businesses are interested in. This material is gradually replacing other types of plastic on the market very well. Refer to the article below with

EuroPlas.

1. Overview of Polyurethane plastic

Polyurethane plastic is a popular material in many manufacturing industries. In particular, PU plastic is flexibly applied to each product with high durability. Therefore, what is Polyurethane plastic and what are its characteristics? Polyurethane compound was first born in 1940 in Leverkusen City, Germany. The material gradually became popular throughout Europe during the 1960s.

PU plastic is the product of the perfect combination of the hardness of metal and the stable elasticity of rubber. This is the reason why this material is an important component in the production of large machine parts at factories. Furthermore, the hardness of PU plastic can be adjusted automatically if the manufacturer changes the content of Isocyanate, Polyol or plastic additives during the preparation process.

All the information about the PU plastic

In particular, Polyurethane plastic material meets production standards in high temperature environments, it is estimated to range from minus 40 degrees Celsius to more than 80 degrees Celsius. Besides, the process of extracting and upgrading Polymer raw materials will form a bond between organic units and carbamate, this will form Polyurethane resin. In the Vietnamese market, PU plastic is also known as plastic rubber.

2. Technical specifications and classification of Polyurethane plastic.

If POM or PP engineering plastics have diverse types and similar properties, Polyurethane plastics are only divided into two main types: Polyether PU and Polyester PU. In particular, both types have chemical structures that are not too different from each other. The weakness of Polyester PU is its water resistance, but its mechanical properties and heat resistance are the strong points of this material.

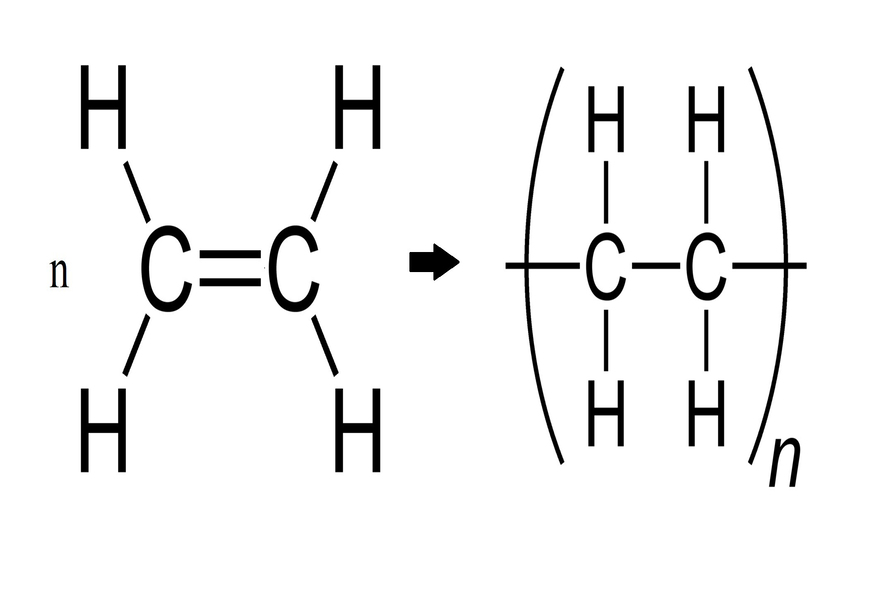

The chemical structure of Polyurethane plastic

Meanwhile, Polyether PU's hydrolysis ability and high temperature resistance will be much better than Polyester PU. However, it will lose to Polyester PU in terms of oil resistance and mechanical properties. EuroPlas will send customers a table comparing the technical specifications of Polyurethane plastic in two types of Polyether and Polyester:

Measurement properties

|

Polyether PU plastic |

Polyester PU plastic |

Proportion

|

1,15g/cm³

|

1,2g/cm³

|

| Hard durability |

88-92A |

88-92A |

| Tensile modulus at 300% |

80-100 |

150-170 |

| Total tension |

200 kgf/cm2 |

520 kgf/cm2 |

| Maximum scalability |

400% |

600% |

| Tensile strength over time |

80kn/m |

140kn/m |

| Ability to recover after impact |

28% |

30% |

| Deformation after compression |

45% |

30% |

| Loss of Akron abrasion |

0,6±2 |

0,08±2 |

To diversify the product line and fully meet consumer needs, the market also offers horizontally networked NPUs. This is an upgraded type of PU plastic that possesses chemical bonds in 3 dimensions. Besides, their chemical structure also has only two parts: hard and soft.

Read more: What is plastic? Everything you need to know about plastic

3. Characteristics of PU material

PU plastic has many outstanding advantages compared to conventional plastic materials:

- Stable abrasion resistance over time: Polyurethane plastic's abrasion resistance is 2-3 times higher than rubber and other metals. This is also the most outstanding advantage of this material. Therefore, they are used as a stable coating on the surfaces of objects such as household appliances.

- Resistance to liquids and impurities: The cells inside PU plastic are inert to water. Therefore, products made from PU plastic will not expand or be damaged when exposed to water for a long time. In particular, the closed chemical structure of Polyurethane plastic not only helps them resist water and dust from the environment but also strange chemical impurities. Therefore, they are commonly used in interior design and prevail over materials such as luxury pallet wood.

PU plastic has stable durability and flexibility

- Heat resistance: As introduced in the beginning, Polyurethane plastic is one of the materials with very good temperature resistance. The temperature fluctuates quite widely from below minus 40 degrees Celsius to over 80 degrees Celsius. Therefore, the material is used in heavy industries or in the production of large industrial machines such as: mining machines, hydraulic machines or printers

- The hardness and elasticity of PU material is 5-6 times better than rubber or regular metals. Furthermore, they also have the ability to bond very well with plastic additives to increase hardness. Therefore, PU plastic can completely withstand great pressure and is perfect for use in making racing tires.

In addition, if we compare with Epoxy in terms of resistance to the sun's ultraviolet rays, PU plastic is many times better. During long exposure to strong ultraviolet rays, Polyurethane plastic does not change color. In particular, you use PU plastic as a coating on the device, this will help save a lot of costs because of the durability and quality of the plastic material.

4. Disadvantages of PU plastic material

Although Polyurethane plastic possesses many advantages from quality to reasonable price, they also have some shortcomings during the construction process. As follows:

- Firstly, EuroPlas will talk about the smell of PU plastic. They will emit a slightly unpleasant, quite strong odor when they are applied in liquid form. That is why factories require workers processing PU plastic to be fully equipped with protective equipment as well as install deodorizer and air filter systems because we will have headaches and dizziness if you are exposed to this smell for a long time. The smell of PU plastic will completely disappear when it converts to solid state.

PU plastic has an unpleasant odor when melted

- Secondly, issues related to the environment. Like other plastic materials, PU plastic also has a fairly small impact on the environment when you burn or melt it. This also affects the quality of the atmosphere. Therefore, units that produce or prepare Polyurethane plastic must have full legal procedures issued by relevant government agencies and ministries.

- Thirdly, the PU plastic production process requires highly skilled and technical workers. You can operate well with specialized machines and control the quality of materials. In addition, you can estimate the content of additives and adjust them to best suit PU plastic. Although Polyurethane plastic is water and moisture resistant, you should limit its exposure to water when the material is in liquid form because the quality will also be affected after it turns solid.

5. Application of Polyurethane resin

The weaknesses of PU do not affect the quality and popularity of this material in production too much.

- Application in the construction industry: PU plastic is a material that can replace wood in interior design. They are moisture and water resistant, so they will minimize termite attacks that cause mold. Besides, the price is also much cheaper than natural wood. In particular, durability and UV resistance will increase product life and ensure safety for housing projects. This also minimizes the amount of heat in the house and creates a feeling of ventilation.

- Application in the electronics industry: The properties of PU plastic are electrical insulating and water resistant, so they are used as an external coating for electrical equipment. In addition, this material is also very popular with underground electrical cable systems. Stable heat resistance also helps PU plastic eliminate most environmental impacts.

Application the Polyurethane plastic in industrial manufacture

- Application in the automobile industry: Because of its elasticity, tensile strength and abrasion resistance, PU plastic is used to produce tires, especially racing cars. They can operate stably on the road for long periods of time and under the impact of high temperatures and great friction.

- Application in the fashion industry: PU plastic can be prepared and formed into small fibers. They are then combined with nylon to produce clothes, this element will help the clothes become soft, light and breathable.Moreover, clothes combined with fibrous PU plastic will have good elasticity and limit environmental impacts as well as not affecting the skin.

- Good application in the construction industry: Currently, with the development of modern equipment, PU plastic is produced in flexible form into products such as floor mats and beds. Besides, they are also made from artificial materials such as imitation wood to protect the environment and save costs.

The application of PU plastic in automobile industry

Finally, PU plastic bars are suitable for the production of metal pipe products, springs or stamping machines and are also used in the mining and metallurgical industries.

6. Introducing plastic additive products at EuroPlas

Plastic additives are essential nutrients added to plastic materials during the manufacturing process. These additives will form desired properties such as: durability, expansion or friction resistance. Because of this, plastic additives help to radically improve the production process and enhance product quality. For example, PU plastic combined with additives will improve durability and high temperature resistance.

The Anti-UV plastic additive

Plastic additive lines at EuroPlas are thoroughly tested before being produced for the market. Europlas provides a variety of plastic additives as follows:

Odor removing additive

The article has provided all information about Polyurethane plastic. This is still one of the most popular materials and brings many benefits to industry and life. In the next part, EuroPlas will help you answer the question: Is PU plastic toxic? Please continue to follow us to update the latest news about plastic products and related news.