When it comes to high-performance plastic materials, Ultem plastic stands in a league of its own. With its remarkable features and applications, it has become a go-to choice for industries seeking top-tier engineering thermoplastics. In this comprehensive introduction, we will uncover the defining characteristics that set Ultem plastic apart and explore the wide range of applications that benefit from its exceptional properties.

1. Understanding the feature of Ultem plastic

1.1. What is Ultem?

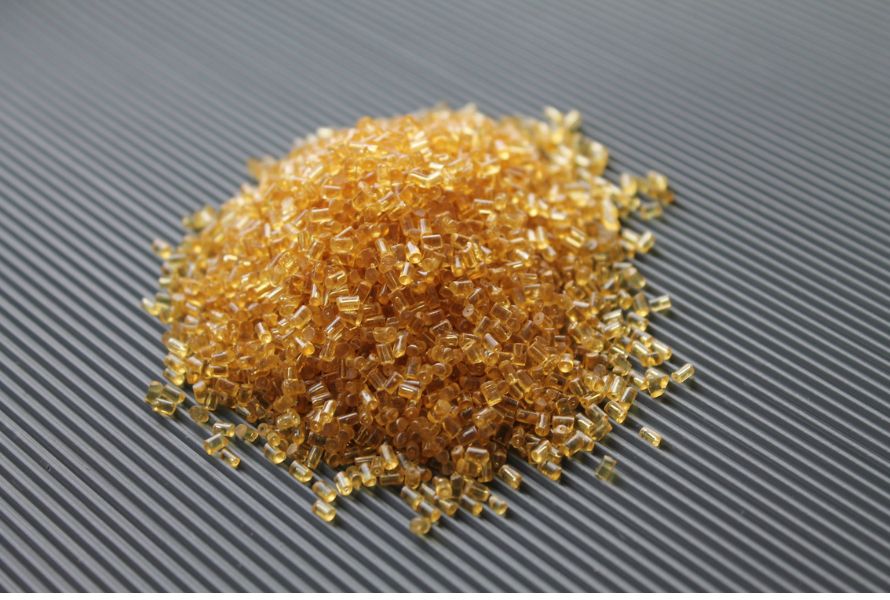

Ultem is a trademarked name for the group of thermoplastic materials known as polyetherimides. It was developed by General Electric's Plastics Division (now SABIC) and has become a leading choice for engineers and manufacturers worldwide. Ultem is known for its outstanding mechanical properties, excellent dimensional stability, and resistance to chemicals and high temperatures.

Ultem, a trademarked name of polyetherimide, is known for its outstanding mechanical properties

1.2. The composition of Ultem

Ultem is composed of polyetherimide resin, which is a high-performance polymer. This resin is characterized by its good thermal stability, high strength, and exceptional chemical resistance. It retains its mechanical properties even at elevated temperatures, making it suitable for applications that demand structural integrity under harsh conditions.

Read more: The Ultimate Guide to High Performance Plastics

1.3. The properties of Ultem

Ultem Plastic, possesses a range of exceptional properties that make it a preferred choice in various industries. Let's explore its key properties as below:

1.3.1. Mechanical strength

Ultem exhibits outstanding mechanical strength, making it suitable for applications that require robust materials. It has high tensile strength and excellent resistance to impact and deformation. Even at elevated temperatures, Ultem retains its mechanical properties, ensuring structural integrity under harsh conditions.

1.3.2. Dimensional stability

Ultem demonstrates remarkably dimensional stability, meaning it maintains its shape and size even when exposed to mechanical stress or temperature variations. It has low creep, which is the tendency of a material to deform over time under constant stress. This property ensures that components made from Ultem retain their intended dimensions and functionality over extended periods.

1.3.3. Chemical resistance

Ultem offers remarkable resistance to chemicals such as acids, bases, solvents, and other aggressive substances. It can withstand exposure to these chemicals without significant degradation or loss of its properties. This makes Ultem suitable for applications where resistance to chemical attack is critical, such as in the chemical processing industry or when manufacturing components for harsh environments.

Ultem works well in resisting to acids, bases, solvents, and other aggressive substances

1.3.4. Thermal stability

Ultem exhibits outstanding thermal stability, allowing it to maintain its properties even at high temperatures. It has a high glass transition temperature (Tg) of around 217°C, which means it can withstand elevated temperatures without softening or losing its structural integrity. This property makes Ultem ideal for applications that involve exposure to heat or require dimensional stability under thermal stress.

1.3.5. Electrical insulation

Ultem possesses outstanding electrical insulation properties. It has high dielectric strength and good electrical insulation capabilities, making it suitable for electrical and electronic applications. This property ensures reliable insulation, preventing electrical current leakage and maintaining proper electrical performance.

1.3.6. Sterilizability

Ultem is compatible with various sterilization methods, including autoclaving, gamma irradiation, and ethylene oxide (ETO) sterilization. This makes it suitable for applications in the medical and healthcare industry, where sterilization is crucial.

2. The applications of Ultem plastic

As a type of polyetherimide plastic, Ultem plastic is widely used across various industries due to its unique characteristics. Let's explore the common applications of its:

2.1. Aerospace and automotive

Ultem is highly valued in aerospace and automotive industries where lightweight materials with exceptional strength and thermal stability are crucial. It finds use in a range of components, including aircraft interiors, automotive engine parts, electrical connectors, and lighting systems. Its ability to withstand high temperatures and maintain mechanical properties makes it a wonderful choice for these demanding applications.

Ultem plastic is well-appreciated in aerospace and automotive industries

2.2. Consumer goods

Ultem is also used in the manufacturing of consumer goods. Its lightweight nature, durability, and resistance to heat and chemicals make it a preferred choice for a variety of consumer products. It finds application in household appliances, sports equipment, consumer electronics, and other products where reliability and performance are essential.

2.3. Medical and healthcare

Ultem's compatibility with sterilization methods, such as autoclaving and gamma irradiation, makes it well-suited for medical and healthcare applications. It is widely used in surgical instruments, medical device housings, and components that require good chemical resistance and durability. Its ability to withstand repeated sterilization cycles without degradation ensures the maintenance of stringent hygiene standards in medical settings.

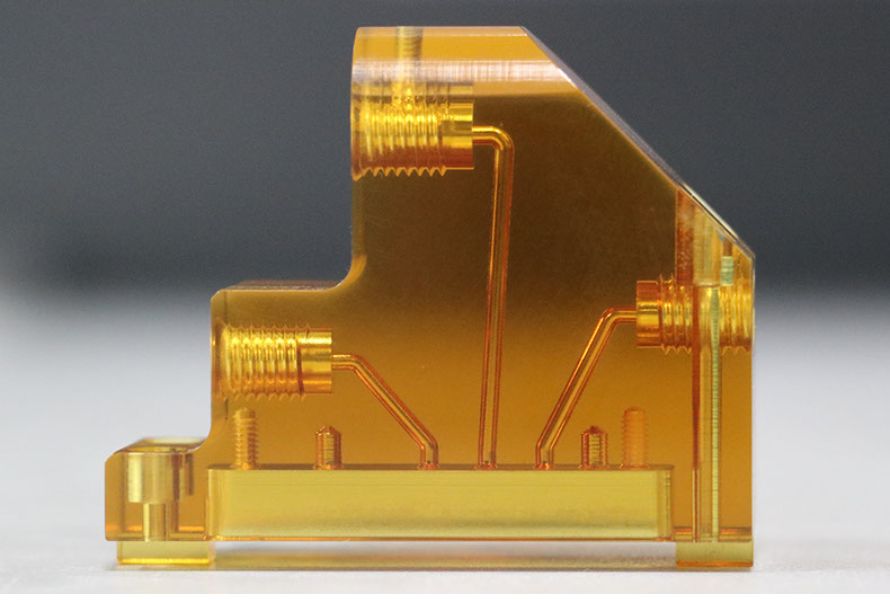

2.4. Electrical and electronics

Ultem is extensively employed in electrical and electronic applications due to its excellent electrical insulation properties. It is commonly used in connectors, sockets, circuit boards, and various insulating components. Its high dielectric strength ensures reliable insulation and prevents electrical current leakage, making it ideal for ensuring the safe and efficient operation of electrical and electronic systems.

Electronic parts made by Ultem ensure the safe operation

2.5. Industrial

Ultem finds applications in various industrial settings. It is employed in chemical processing equipment due to its exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. Additionally, it is utilized as electrical insulation for industrial machinery, where its high temperature resistance and robustness are valuable. Ultem's ability to withstand harsh environments and maintain its mechanical and electrical properties make it well-suited for industrial applications.

3. Some disadvantages of Ultem plastic

While Ultem plastic offers numerous advantages, it also has some potential disadvantages:

3.1. Hot molds in injection molding

Ultem plastic requires molds to be heated during the injection molding process, adding complexity and potentially increasing production costs.

3.2. Susceptibility to stress cracking

Based on polyetherimide resin, Ultem can be vulnerable to stress cracking when exposed to polar chlorinated solvents. This limitation requires careful consideration of chemical compatibility and may restrict its use in certain applications.

3.3. Higher cost

Ultem plastic tends to be more expensive compared to other engineering thermoplastics, which can impact overall project costs.

Ultem plastic is often associated with higher costs when compared to other engineering thermoplastics.

3.4. Processing challenges

Ultem plastic has a high melting point and viscosity, making it more difficult to process and fabricate. Specialized equipment and expertise may be required for optimal results.

3.5. Surface defects and dimensional instability

Improper control during manufacturing processes can lead to surface defects or dimensional instability in Ultem plastic parts, requiring careful attention to quality control measures.

4. Conclusion

In conclusion, Ultem plastic, also known as polyetherimide (PEI), is a high-performance engineering thermoplastic with exceptional properties. It finds applications in aerospace, automotive, electrical and electronics, medical and healthcare, industrial, and consumer goods industries. With its versatile characteristics, Ultem plastic offers a reliable and efficient solution for a wide range of demanding applications.

We hope that this article has provided you with valuable and insightful information. To stay updated with the latest information, be sure to explore other insightful articles on our blog.

Furthermore, when it comes to sourcing high-performance plastic, EuroPlas is your trusted supplier. With over 15 years of industry expertise and a steadfast commitment to delivering top-quality materials, we have established ourselves as a reliable partner for manufacturers across diverse industries. Don't hesitate to reach out to us HERE to be consulted more about benefit from our exceptional products and services.