Nylon, a synthetic material that has become popular in our modern world, is known for its durability, elasticity, and flexibility. This material has helped revolutionize industries from fashion and textiles to automobiles and engineering. Nylon's impact on everyday life cannot be underestimated, because of unexpected changes, from the fabrics in the garment industry to the parts that power machines. In this article, let's dive into surprising facts about Nylon that you may not know.

1. A Versatile Synthetic Material

Nylon is a synthetic polymer, which means it is made up of long chains of repeating units. It was first developed in the late 1920s by a team of chemists at DuPont, led by Wallace Carothers. The goal was to create a synthetic alternative to silk, which was expensive and in short supply at the time. After several years of research and experimentation, they successfully created Nylon, which was initially used in toothbrush bristles and women's stockings.

Today, Nylon is used in a wide range of products due to its unique properties. Let's take a look at some of its most common applications:

- Fashion and apparel: Nylon is extensively used in the production of clothing, sportswear, lingerie, and hosiery due to its lightweight, wrinkle-resistant, and moisture-wicking properties. It is also commonly blended with other fabrics to improve their strength and durability.

- Home furnishings: Nylon's durability and resistance to stains and fading make it a popular choice for carpets, upholstery, curtains, and other home décor items. It is also used in outdoor furniture due to its ability to withstand harsh weather conditions.

- Industrial applications: Nylon's strength and resistance to wear and tear make it suitable for use in ropes, conveyor belts, fishing nets, and industrial fabrics. It is also used in the production of parachutes and other military equipment.

- Automotive industry: Nylon is used in the manufacturing of tires, hoses, and other automotive components due to its resilience and resistance to heat and chemicals. It has also been used in the development of electric cars, as it is a lightweight and durable material.

- Electronics: Nylon to produce components such as connectors, insulators, and circuit board fasteners.

- Aerospace: Nylon is used in the aerospace sector for producing components such as fasteners, bearings, and structural parts.

2. How Nylon Was First Discovered

To fully understand the significance of Nylon's discovery, we must look at the historical context and key figures involved in its development. The early 20th century saw a rise in the demand for synthetic materials, as natural resources such as silk, cotton, and rubber were becoming scarce. Scientists and inventors were constantly searching for new ways to create synthetic alternatives that could match or even surpass the properties of these natural materials.

Wallace Carothers, a chemist with a Ph.D. from the University of Illinois, was one of the pioneers in this field. He joined DuPont in 1928 and was tasked with finding a synthetic alternative to silk. After several years of research and experimentation, he and his team successfully created Nylon, which was hailed as a breakthrough in the world of synthetic materials.

The story of Nylon's discovery is a fascinating tale of scientific exploration and serendipitous accidents. In 1930, Wallace Carothers and his team at DuPont were experimenting with different polymers when they stumbled upon a compound that could be spun into fibers. This was the birth of Nylon, which was initially known as "fiber 66" before being officially named "Nylon."

It was exactly that Nylon was patented in 1935, which DuPont had hoped for. It hit markets in 1939, becoming an instant success, especially as a silk replacement in hosiery. Carothers didn't foresee his work's broad impact on consumer goods like toothbrushes, fishing lines, and lingerie, or in special uses like surgical thread, parachutes, and pipes. Nylon truly marked the beginning of the era of synthetic materials.

Unfortunately, Carothers did not live to see the full impact of his discovery. He struggled with depression and took his own life in 1937, just a few years after Nylon's commercial success. However, his contributions to the development of Nylon and other synthetic materials have been recognized and celebrated by the scientific community.

3. Nylon and its effects on the Fashion and Textile Industries

Nylon's versatility in applications has had a significant impact on various industries, but perhaps none more so than the fashion and textile industry. Let's take a closer look at how Nylon revolutionized this industry and became an essential material in our wardrobes.

3.1. Versatility in applications

One of the main reasons for Nylon's popularity in the fashion industry is its versatility. It can be used to create a wide range of fabrics with different properties, making it suitable for various clothing items. For example, Nylon can be spun into fine fibers that are soft and silky, perfect for lingerie and hosiery. It can also be woven into thicker fabrics that are more durable and suitable for outerwear.

Nylon's ability to blend well with other fabrics has also contributed to its widespread use in the fashion industry. It is commonly blended with cotton, wool, or silk to improve the strength and durability of these natural materials. This has allowed designers to create innovative and functional garments that would not have been possible without Nylon.

3.2. Historical significance and popularity of Nylon stockings

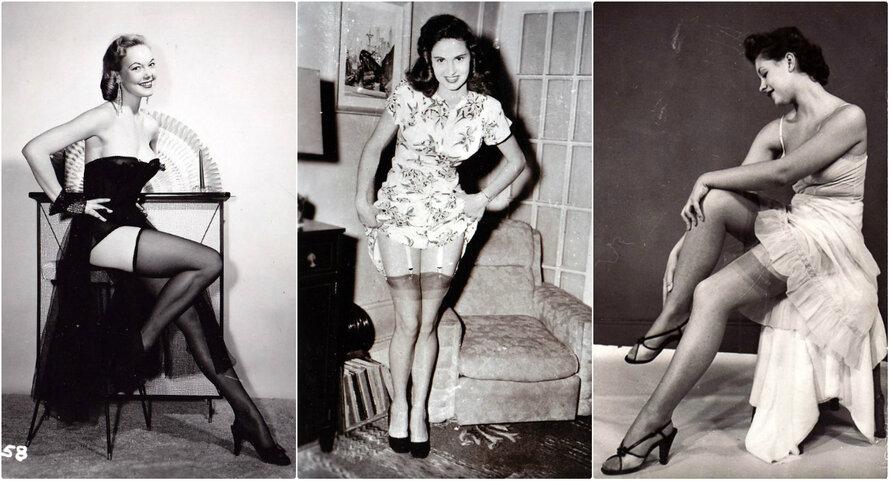

Nylon stockings have been loved and sought after since their debut

Nylon stockings, also known as Nylons, were a sensation and quickly became a symbol of modernity and luxury. They were considered a more affordable alternative to silk stockings, which were highly coveted but expensive.

When Nylon was first introduced to the public in 1939, it caused a sensation. The first Nylon product to hit the market was stockings, which were marketed as a cheaper and more durable alternative to silk stockings. They were an instant success, with over 72,000 pairs being sold on the first day of their release.

The popularity of Nylon stockings continued to grow throughout the 1940s and 1950s, with women all over the world embracing this new fashion trend. However, due to the shortage of Nylon during World War II, the production of Nylon stockings was halted, leading to a black market for them. This further increased their desirability and cemented their place in fashion history.

4. Products made from Nylon

Nylon's versatility has led to its use in a wide range of products, both in our daily lives and in various industries. Let's take a look at some of the most common products made from Nylon.

- Clothing: Nylon is commonly used in clothing items such as hosiery, sportswear, swimwear, and raincoats. Its elasticity and strength make it ideal for these types of garments.

- Carpets: As mentioned earlier, Nylon is a popular material for carpets due to its durability and stain resistance. It is often used in high-traffic areas where a strong and durable carpet is needed.

- Ropes and cords: Nylon ropes and cords are widely used in boating, camping, and other outdoor activities. They are strong, lightweight, and resistant to abrasion and chemicals.

- Electrical insulation: Nylon films are used in electrical insulation due to their excellent dielectric properties. They are also used in the production of capacitors and other electronic components.

- Automotive parts: Nylon is used in the production of various automotive parts, such as gears, bearings, and bushings. Its strength and resistance to wear make it suitable for these applications.

- Medical devices: Nylon is used in medical devices such as artificial hearts and sutures due to its biocompatibility and strength.

- Musical instruments: Nylon strings are commonly used in classical guitars and other stringed instruments due to their elasticity and durability.

- Toothbrushes: The bristles of toothbrushes are often made from Nylon due to their flexibility and resistance to bacteria.

- Food packaging: Nylon's moisture-resistant property and ability to seal in freshness make it an excellent choice for food packaging. It is commonly used in packaging materials like pouches, wraps, and films.

- Cookware: Nylon is employed in the production of heat-resistant and non-stick cookware, such as kitchen utensils, spatulas, and ladles. Its ability to withstand high temperatures and resist sticking to food surfaces makes it suitable for cooking applications.

5. Nylon's Use in Sports Equipment and Apparel

Nylon is commonly used in sports apparel and equipment

Nylon has become a staple material in the sports industry, with its use in everything from running shoes to tennis rackets. Its contribution to the performance and durability of athletic gear is unmatched, making it a favorite among athletes and sports enthusiasts alike.

5.1. Nylon's strength and durability in sports equipment

One of the most significant advantages of using Nylon in sports equipment is its strength. Pound for pound, Nylon is stronger than steel, making it ideal for applications where durability is crucial. For example, Nylon is commonly used in ropes, parachutes, and even bulletproof vests due to its high tensile strength.

In addition to its strength, Nylon is also highly resistant to abrasion. This makes it suitable for use in gears, bearings, and other components of sports equipment that undergo constant wear and tear. As a result, Nylon helps to extend the lifespan of these products, saving both time and money for manufacturers and consumers.

5.2. Nylon's Flexibility and Resilience in Athletic Apparel

In addition to its use in sports equipment, Nylon is also a popular choice for athletic apparel. Its high degree of elasticity allows it to stretch and return to its original shape without breaking, making it perfect for clothing that requires a snug fit. This property also makes it ideal for medical devices such as compression stockings and braces.

Moreover, Nylon's flexibility and resilience contribute to the comfort and performance of athletes. It allows for a full range of motion without restricting movement, making it a preferred material in activewear and sports gear.

6. Physical and Chemical Properties of Nylon

Nylon's strength and flexibility are just some of the remarkable properties that have made it a popular material in various industries. Let's take a closer look at some of its other physical and chemical properties that make it stand out from other synthetic materials.

6.1. Strength and durability

As mentioned earlier, Nylon is incredibly strong and durable, with a tensile strength that surpasses that of steel. This property is due to its long-chain molecules that are tightly packed together, giving it excellent resistance to external forces.

Moreover, Nylon's molecular structure also makes it resistant to impact and fatigue, making it an ideal material for products that undergo repetitive stress, such as gears and bearings.

6.2. Flexibility and resilience

Nylon's high degree of elasticity is another unique property that sets it apart from other materials. Its long-chain molecules can stretch up to 300% of their original length without breaking, making it highly flexible and resilient.

This property is essential in applications where the material needs to withstand bending or twisting without losing its shape, such as in clothing and medical devices.

6.3. Resistance to chemicals

Nylon is also highly resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes it suitable for use in harsh environments where exposure to chemicals is inevitable, such as in industrial settings.

Moreover, this resistance to chemicals also makes Nylon a preferred material in medical devices, as it can withstand exposure to bodily fluids and cleaning agents without degrading.

7. Sustainability aspects of Nylon

Bio-nylon is produced to solve environmental problems

While Nylon has many desirable properties, its production and disposal have raised concerns about its impact on the environment. However, there have been efforts to address these issues and make Nylon a more sustainable material.

7.1. Recycling Nylon

One way to reduce the environmental impact of Nylon is through recycling. Nylon can be recycled into new products, such as carpets, clothing, and even automotive parts. This not only reduces waste but also conserves resources and energy that would have been used in producing new Nylon.

Moreover, some companies have started using recycled Nylon in their products, promoting a circular economy and reducing their carbon footprint.

7.2. Eco-friendly alternatives

Another approach to making Nylon more sustainable is by developing eco-friendly alternatives. For example, bio-based Nylon is made from renewable resources such as corn or castor oil, reducing its reliance on fossil fuels.

Additionally, researchers are exploring ways to make Nylon production more environmentally friendly by using less water and energy and reducing greenhouse gas emissions.

8. Future Prospects of Nylon: A Promising Outlook

The Nylon market is poised for consistent growth in the upcoming years, fueled by the rising need for lightweight, high-performance materials across various industries. Market participants should prioritize the development of sustainable and bio-based Nylon materials, explore novel applications and markets, and engage in collaborations with industry stakeholders to address environmental concerns. The future prospects for the Nylon market are optimistic, offering opportunities for innovation and sustainable expansion.

Key points about the global Nylon market include:

- Anticipated steady growth in the global Nylon market over the future.

- Textiles and automotive industries maintain a significant market share due to the demand for Nylon fibers and engineering plastics.

- Asia Pacific stands as the dominant market, driven by rapid industrialization and the growth of end-use industries, particularly in China and India.

- The emphasis on sustainable and eco-friendly Nylon products is opening up new market avenues.

Factors contributing to the growth of the Nylon market include:

- Escalating demand for lightweight and high-performance materials across diverse industries.

- Outstanding mechanical properties of Nylon, including strength, durability, and heat resistance.

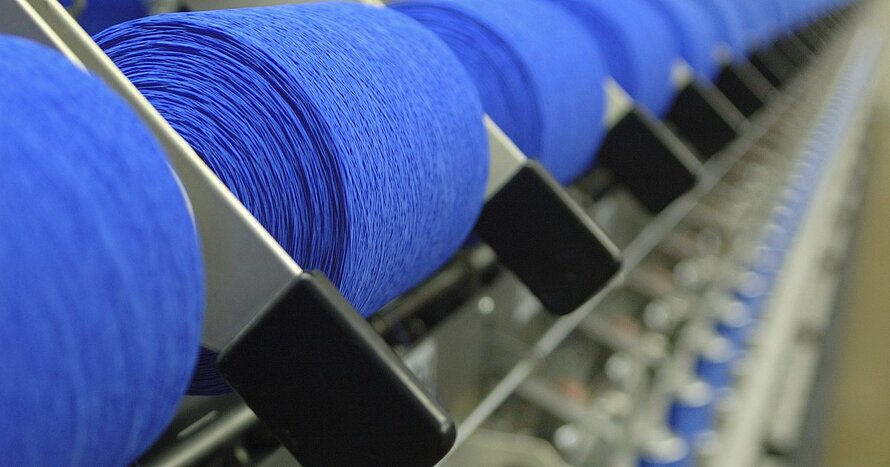

- Increasing adoption of Nylon fibers in the textile sector.

- Expansion of the automotive industry, necessitating Nylon-based components for weight reduction and enhanced fuel efficiency.

Read more: How many types of Nylon? Properties & Common uses

9. Nylon Innovations

Nylon has had many improvements and is increasingly used more commonly

Nylon, a synthetic polymer developed in the 1930s, has evolved significantly in production methods and material properties. The shift from batch to continuous production processes has greatly enhanced efficiency by enabling uninterrupted synthesis. New Nylon variations, such as Nylon 6, Nylon 66, and Nylon 12, cater to specific applications with improved thermal stability and abrasion resistance.

Technological advancements like metallocene catalysts and reactive extrusion have contributed to refining Nylon properties and streamlining the production process. These innovations allow for precise control over polymerization, ensuring higher product quality and consistency.

Recent trends in Nylon production emphasize sustainability. Companies are actively pursuing environmentally friendly practices, including the use of bio-based monomers, recycling Nylon waste, and developing biodegradable Nylon alternatives. This reflects the industry's commitment to reducing the environmental impact of Nylon production.

10. Nylon as a Replacement Material

Nylon's versatility and durability have made it a popular replacement material for traditional materials in various industries. Let's take a look at some examples of how Nylon is replacing other materials and improving performance.

10.1. Nylon vs. Silk

Nylon was initially developed as a substitute for silk during World War II when the supply of silk from Asia was cut off. Today, Nylon is still used as a replacement for silk in many applications, including clothing, hosiery, and parachutes.

10.2. Nylon vs. Cotton

Cotton has long been a popular material in the textile industry, but Nylon's strength and durability have made it a preferred alternative in some cases. For example, Nylon is commonly used in activewear and swimwear, where cotton would not hold up well under constant use and exposure to water.

10.3. Nylon vs. Steel

In the automotive industry, Nylon is increasingly being used as a replacement for steel in various components. It offers similar strength and durability while being significantly lighter, resulting in improved fuel efficiency and reduced emissions. For example, replacing steel with Nylon in a car's engine cover can reduce its weight by up to 50%.

In conclusion, Nylon is a versatile material. Thanks to its unexpected properties, Nylon has become an essential part of life. The surprising facts about Nylon mentioned above really make us realize the importance of this synthetic material and the change that Nylon brings. From being invented and leading to a global revolution - Nylon socks, to a series of popular applications in many different industries, and even contributing to future sustainability efforts. Today, Nylon continues to innovate and promises to bring many other great values.

Follow EuroPlas's blog to learn the latest and most useful information about materials worldwide and current trends in using materials!