3D printing PLA (Polylactic Acid) is one of the most widely used materials in FDM 3D printing thanks to its eco-friendliness, ease of use, and affordability. However, during real-world printing, PLA can still encounter several issues that affect print quality.

Below are 5 common problems when using 3D printing PLA and how to effectively troubleshoot them to optimize your printing process and improve the final result.

Understanding the root causes of these errors and how to address them can help save time and improve overall print performance when working with 3D printing PLA.

1. First layer not sticking to the bed

The first layer is arguably the most important layer in any 3D printing PLA project. If this layer doesn't adhere properly, the entire print may fail. It provides the foundation for every layer that follows, and when it's misaligned or lifts off, you risk wasted material and time.

The first layer is arguably the most important layer in any 3D printing PLA project.

Symptoms:

You may notice the print detaching from the bed partway through printing, or the corners curling up instead of staying flat. Sometimes, the extruder seems to be working normally, but the filament doesn’t stick—indicating poor bed adhesion.

Causes:

Poor bed leveling is one of the most frequent causes. The nozzle may be too far from the bed in certain areas, leading to insufficient filament squish. A cool or unclean bed surface, or printing too fast for the first layer, can also result in failed adhesion, especially with 3D printing PLA.

How to fix:

- Check and recalibrate bed leveling

- Increase bed temperature to 50–60°C

- Apply glue stick, painter’s tape, or PEI sheet for better adhesion

- Enable brim or skirt in your slicing software to increase surface contact

2. Nozzle clogging

Nozzle clogging is a frustrating yet common issue in 3D printing PLA, especially during longer or multi-part prints. It disrupts the extrusion flow and compromises the structural integrity of your object.

Nozzle clogging is a frustrating yet common issue in 3D printing PLA, especially during longer or multi-part prints.

Symptoms:

The extruder might click or skip, and you'll see incomplete lines or sudden gaps in the print. Sometimes, nothing comes out of the nozzle at all, despite the filament being properly loaded and the temperature appearing correct.

Causes:

PLA is hygroscopic and easily absorbs moisture from the air. This moisture causes bubbling and clogging when heated. Residual burnt plastic from previous prints or low printing temperatures can also restrict flow. Cheap filament with inconsistent diameters contributes to jamming.

How to fix:

- Use high-quality filament stored in dry conditions

- Perform a cold pull to clean the nozzle

- Clean the nozzle regularly or replace it if needed

- Raise the printing temperature within the recommended range (190–220°C)

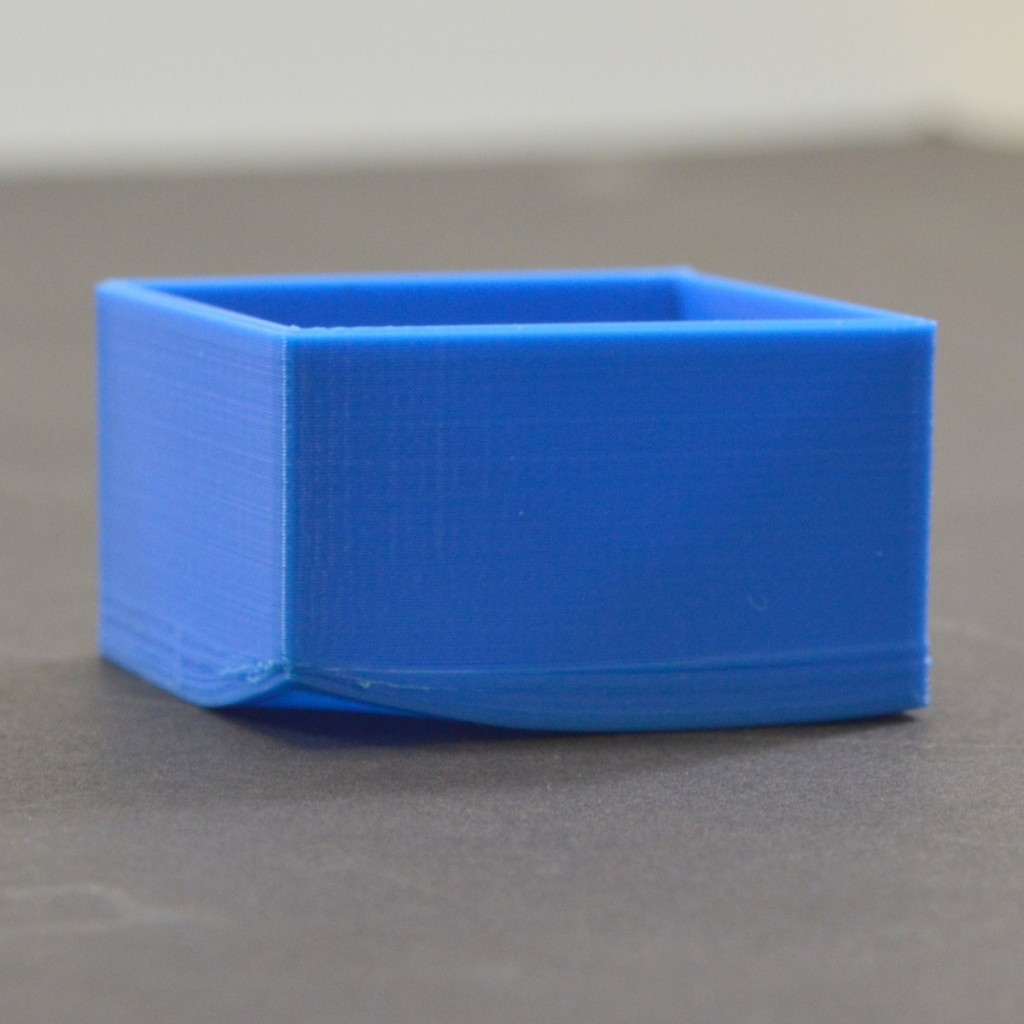

3. Warping and shrinkage

While 3D printing PLA tends to warp less than materials like ABS, it’s still susceptible to temperature fluctuations. Warping can distort your model, ruin dimensional accuracy, and even cause prints to fail halfway through.

While 3D printing PLA tends to warp less than materials like ABS, it’s still susceptible to temperature fluctuations.

Symptoms:

Common signs include corners peeling off the print bed or upward curling of edges. The base layer may no longer be flat, causing uneven stacking of subsequent layers.

Causes:

Uneven cooling is the primary cause. If a draft hits the print or the room is too cold, PLA may contract too quickly, resulting in shrinkage and warping. Thin parts and sharp corners are especially vulnerable.

How to fix:

- Print in an enclosed chamber or use a cover

- Maintain a stable room temperature

- Use a heated bed with good surface adhesion materials

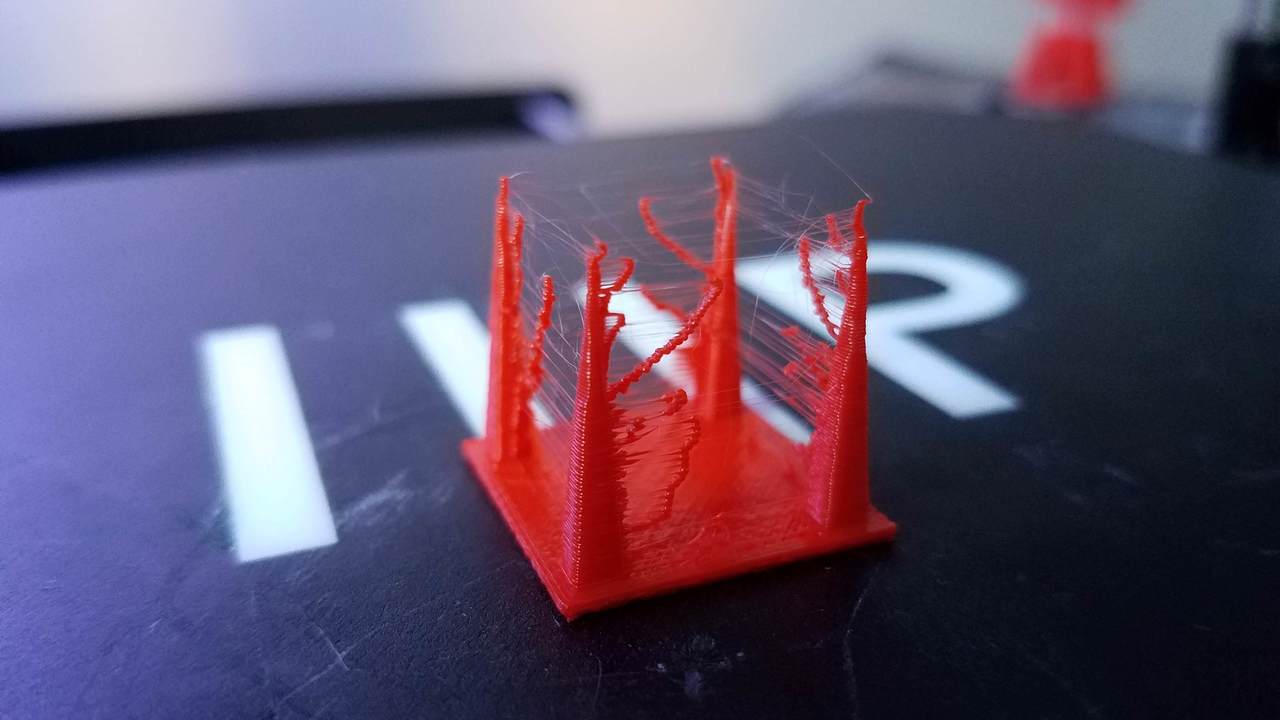

4. Stringing (unwanted filament strings)

Stringing is a visual blemish that frequently affects 3D printing PLA, especially when printing objects with multiple gaps, arms, or columns. It’s caused by molten PLA oozing out of the nozzle as it moves between sections.

Stringing is a visual blemish that frequently affects 3D printing PLA.

Symptoms:

You’ll observe hair-like threads spanning between the model's structures. These filaments are often delicate but can ruin the aesthetics of your part and increase post-processing time.

Causes:

A nozzle that is too hot can make PLA flow more than intended. Improper retraction settings will fail to pull back the filament during travel moves. Printing too slowly can also worsen stringing.

How to fix:

- Lower the nozzle temperature closer to the lower range (190–200°C)

- Enable retraction and fine-tune retraction distance (3–6 mm)

- Increase retraction speed (25–45 mm/s)

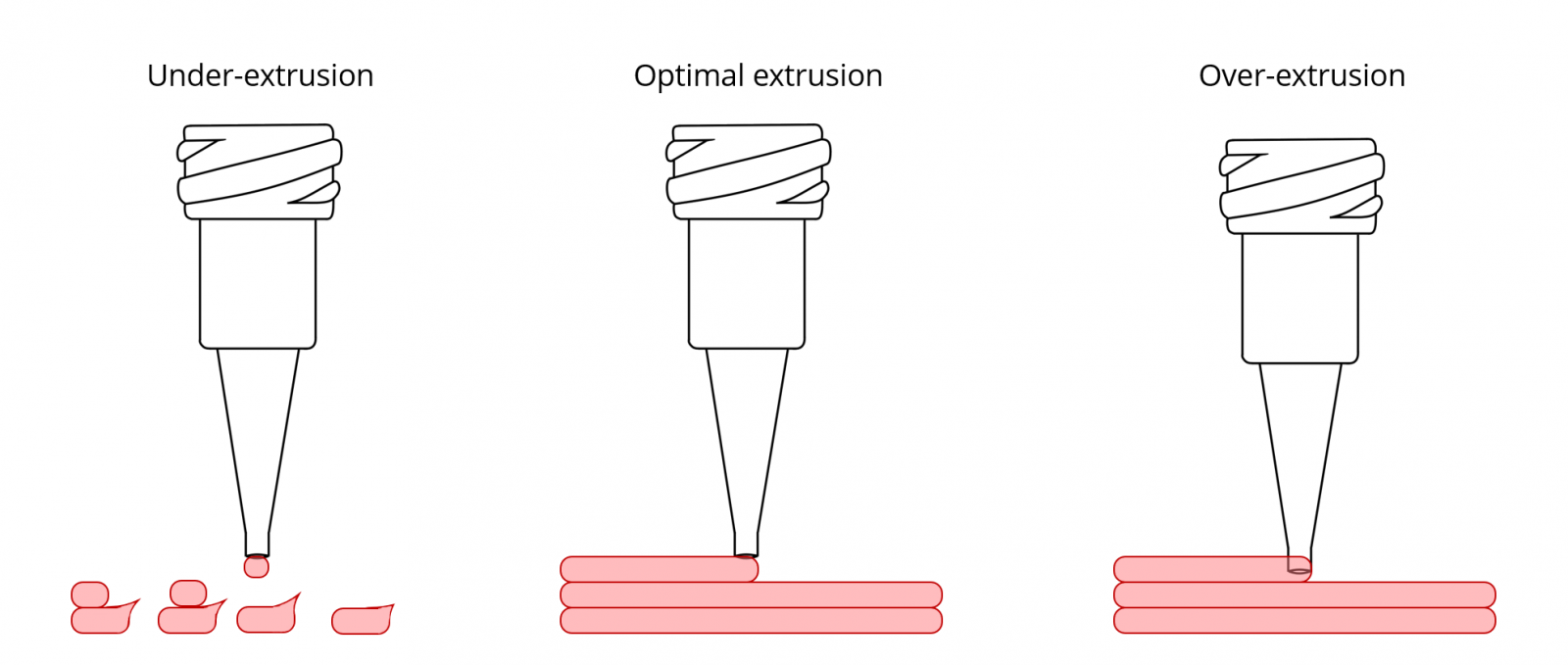

5. Uneven extrusion (under/over extrusion)

A smooth extrusion flow is key to achieving crisp, high-quality layers in 3D printing PLA. When filament flow fluctuates, surface defects become visible and structural weaknesses emerge.

A smooth extrusion flow is key to achieving crisp, high-quality layers in 3D printing PLA.

Symptoms:

The surface might look inconsistent, with thin lines or blobs, and gaps may appear within walls or infill. The extruder may also make grinding noises or fail to extrude completely.

Causes:

This issue is often mechanical. A partially blocked nozzle, worn-out drive gear, or slipping filament can all disrupt extrusion. Incorrect filament diameter settings or miscalibrated flow rates in your slicing software can also be responsible.

How to fix:

- Recalibrate your printer’s flow rate

- Clean or replace extruder gears

- Use high-quality filament with consistent diameter (1.75 ± 0.03mm)

6. Conclusion

Although 3D printing PLA is user-friendly and widely accessible, maintaining high-quality results requires careful monitoring and adjustment. Whether you’re a beginner or a professional, mastering how to identify and solve common PLA printing problems helps reduce waste and improve final product quality.

7. About EuroPlas

EuroPlas is one of the world's largest plastic masterbatch manufacturers, operating seven factories in Vietnam and Egypt with a total annual capacity of up to 800,000 tons. EuroPlas products are distributed to over 95 countries worldwide.

EuroPlas offers the BiONext product line, made from renewable biomass sources such as polylactic acid (PLA), polyhydroxyalkanoate (PHA), plant-based materials (corn, palm oil, potatoes), or fossil-based materials such as aliphatic-aromatic co-polyester (PBAT).

Explore more on the EuroPlas Blog or contact us via our Contact Page.