3D printing vs Injection molding

Currently, 3D printing vs injection molding is leading the production trend with many benefits for both manufacturers and consumers. However, there are still many questions about which is more suitable, 3D printing vs injection molding? Understanding the benefits and limitations of these two methods will help you consider the appropriate technique for your current product. Let's learn about some important notes about 3D printing vs injection molding right below!

1. What is 3D printing?

3D printing is an additive manufacturing technology

3D printing technology is being widely applied in the market for many different business purposes. 3D printing is favored by many manufacturers because it is one of the methods that offers many advantages over other traditional production methods. For example, the benefits of saving time, saving costs, accommodating complex designs and many other benefits. The term 3D is an abbreviation for 3-Dimension. 3D printing is an additive manufacturing technology to create 3-dimensional objects according to the desired design. In the 3D printing industry, material layers will be set up sequentially by the printer or printing software and looped until the product is complete. That is, the material layers are stacked and combined with each other. together create visual effects. 3D printing technology also brings many benefits such as being able to print complex shapes, but the process is simpler and saves materials compared to other printing methods. Depending on the printing type, 3D printing takes different amounts of time to complete. For simple designs, 3D printing only takes a few minutes. Many investors choose 3D printing because the investment cost is quite low, it can create many complex geometries, the implementation time is quick and there are many supporting software tools.

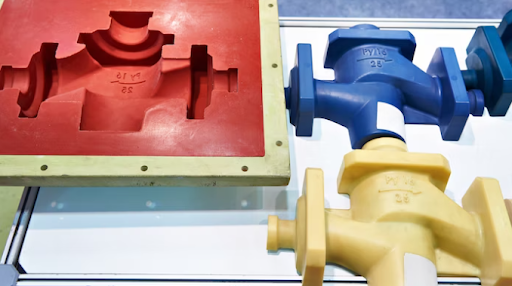

2. What is injection molding?

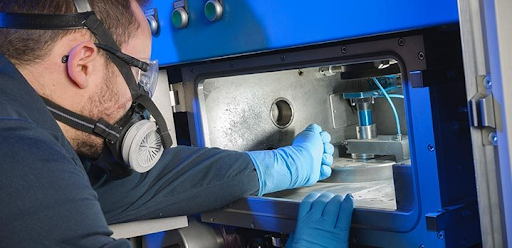

Injection molding can produce a large quantities of products

Besides 3D printing, injection molding is also an extremely popular application in a variety of manufacturing industries. Injection molding allows the production of large quantities of products according to the manufacturer's design. This is a specific mold forming method that is a form of injecting molten material into the mold cavity under strong pressure conditions. The material injected into the mold is cooled and solidified, thereby obtaining the finished product as expected. Injection molding is one of the superior methods and is suitable for mass production processes to create finished products of thousands of identical items. Common plastic materials are often applied injection molding methods such as thermoplastics or thermosetting plastics.

Read more: What is injection molding? How does it work?

3. Advantages and disadvantages: 3D printing vs Injection molding

3.1 3D printing

3D printing has a lot of advantages

3.1.1 Advantages

An advantage is that 3D printers operate by pre-set programs so the operator does not need to monitor them all the time. Besides, 3D printing is considered a one-step manufacturing process that does not require sophisticated equipment. From there, 3D printing helps optimize related costs such as investment and operating costs of machinery, human resources for supervision, and saving time. In addition, the production process only uses the amount of material needed for the product to be created, thereby helping to avoid wastage of materials. This saves costs and is more environmentally friendly than methods of cutting and shaping from large blocks of non-recyclable materials.

- Fast design and production

3D printing can produce parts quite quickly within a few minutes to a few hours depending on the complexity of the design. This is one of the advantages compared to many other traditional methods. The design process is also quite quick because there are many supporting software such as creating STL or CAD files, etc.

- Can print based on diverse needs

Unlike media production processes, 3D printing can print according to customer requirements, so it does not require much storage space when printing a series of sample products for customer reference. Instead, customers can refer to the models on the virtual library under STL or CAD files, and when deciding which model they will print. Editing designs as required is also quicker and easier, avoiding outdated designs and piled-up inventory.

- The printed pattern is durable, beautiful and lightweight

3D printing is very popular in plastic materials, and the top characteristic of plastic is its durability and lightness. In industries such as aerospace and automotive technology, lightweight products will bring great benefits in fuel savings. 3D printed plastic products meet a variety of usage needs such as hardness, good heat resistance, high durability, waterproof and less chemical wear.

3.1.2 Disadvantages

3D printing has a limited print size

Currently, because the printing chamber size is not too large, the size of the printed product is also limited. In this case, the 3D printer will be set up to print many small parts and assemble them together.

Currently, plastic and some metals can be used for 3D printing, but plastic is still more popular. However, material selection can be difficult because not all metals or plastics can be temperature controlled enough to allow 3D printing.

3.2 Injection molding

Injection molding has a lot of advantages

3.2.1 Advantages

Injection molding helps create large quantities of products that are identical down to every detail. For products that require elaborate details or complex shapes, injection molding meets the similarity of a series of products. In addition, for products that require uniformity and high precision, injection molding is an ideal choice.

This method provides a mass production process but saves a lot of costs compared to traditional production methods. Producing large quantities of products requires a lot of investment in production equipment, but for injection molding, investing in equipment is not too complicated.

- Mass production capability

Injection molding provides outstandingly high production efficiency. After the mold is designed, the mold injection process will take place at an extremely fast speed (cycle is about 10 - 20 seconds depending on complexity). This allows manufacturers to produce an average of 10,000 products to more than 100,000 products in much less time than traditional manufacturing processes. Investors can even increase output many times depending on the scale and purpose of the business.

Unlike 3D printing, injection molding is hardly limited to plastic materials, you can choose from a variety of plastics based on product characteristics and your business plan. For injection molding, investors can use additional fillers in the molding material to increase the durability of the product.

3.2.2 Disadvantages

Injection molding need a great care

- The design stage requires great care

When designing for the injection molding process, factors such as the location of gates, nozzles and cooling lines must be carefully considered, avoiding cuts and sharp edges, and the design of a large number of molds is also difficult to change.

- Limit size for large prints

For giant parts, giant hooks are needed to create injection molds. Manufacturing giant injection molds can also incur additional costs.

4. Application comparison: 3D printing vs Injection molding

4.1 The top applications of 3D printing are:

3D printing is applied in health care

Thanks to the advantages of higher accuracy, higher complexity, faster construction and cost savings, 3D printing is applied to 3D printing of concrete, pouring foundations and building construction site walls, Modules for on-site assembly, architectural scale models, etc

Create samples and product models: 3D printing is ideal for projects that require frequent design upgrades and updates. Editing 3D printed models and printing takes place in an extremely short time compared to many other types of production.

Health care: healthcare products that are commonly 3D printed include dental appliances, dental crown molds, aligners, personalized prosthetics, hearing aids, and orthopedic insoles. etc

3D printing is commonly used in the aerospace industry to create product development models. One of them can be mentioned as serving the process of researching and improving aircraft parts.

In the automotive industry, 3D printing is applied to produce spare parts, design components on demand, create product research samples, etc.

4.2 The top applications of injection molding are:

Injection molding is applied in health care

Unlike 3D printing, injection molding is used in the construction industry for a number of other purposes. The framing method is most commonly used in the construction industry including small and large fittings, screws and various hand tools.

The products that injection molding creates include beverage containers, food containers, beverage filtration and dispensing parts, etc. However, these products need to comply with strict health rules and regulations under programs such as GMA safety or FDA certification. In addition, molded parts must be BPA-free and completely non-toxic.

Just like applications in the food industry, injection molding in the medical industry needs to comply with strict health safety regulations. In this case, manufacturers must use medical or FDA-grade plastics and produce their parts according to ISO certification.

Products that injection molding creates in the automotive industry include bumpers, mirror covers, cup holders, dashboard sets, etc. Injection molded products can meet requirements such as durability, beauty, long life, and hardness.

5. Conclusion

In general, both 3D printing and injection molding technologies are very popular in the market. Through the above research, it can be seen that 3D printing and molding both have outstanding advantages over other conventional production methods. To choose the appropriate printing method, you need to consider the number of products, print size, purpose and business plan. Visit more useful shares at EuroPlas to update optimal solutions in material selection!