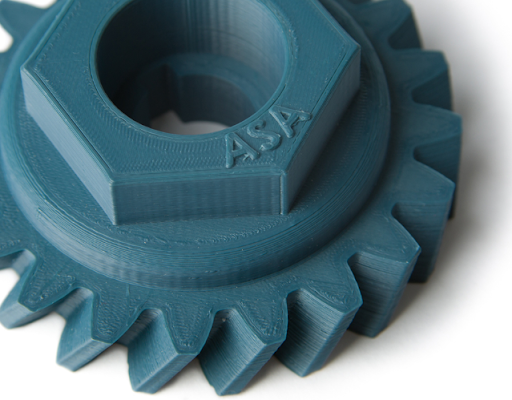

A gear 3D printed using ASA plastic

Properties such as durability, hardness, insulation, heat resistance, weather resistance, and durability over time are always beautiful words that people give to ASA plastic materials. Also because of the great properties of ASA plastics, they gradually build a solid foothold in many different manufacturing industries. Among them are the automotive technology industry, outdoor campus manufacturing, amusement parks, backyards, and some applications in the electrical field. The outstanding product effects brought about by ASA plastic have been clearly demonstrated through many application projects. However, understanding the properties and parameters of ASA plastic is an indispensable step for any production process. Let's find out below so that ASA products will be manufactured with the most ideal parameters.

1. What is ASA plastic?

ASA plastic is quite commonly used in many different production

ASA plastic has long been one of the brightest candidates for many investors with its economic benefits as well as leading product performance in the materials industry. ASA plastic is also known by its full name Acrylonitrile styrene acrylate. This is a synthetic, amorphous thermoplastic with the chemical formula C18H23NO2. During the copolymerization of acrylonitrile and styrene, a grafted acrylic ester elastomer (in powder form) is added and ASA is obtained. In particular, to create ASA plastic, butadiene rubber is a very important factor. In terms of properties, ASA Plastic has good weather resistance, good heat resistance, and commendable resistance to chemicals, UV rays and some radiation. Currently, ASA plastic is quite commonly used in many different production processes such as hot pressing, injection molding, extrusion, blow molding, 3D printing, etc. Thanks to its good weather and radiation resistance properties, ASA is ideal choice for outdoor applications. Some industries have high demand for ASA such as automotive technology, electronic equipment, outdoor tools, etc.

2. ASA plastic properties

As mentioned above, ASA plastic is one of the materials that is highly rated for its durability, hardness, impact resistance, and high weather resistance. Specifically, ASA plastic has a wide range of heat resistance levels from very low to very high, so it is suitable for a variety of weather conditions. Besides, ASA resin also has chemical resistance properties such as salt solutions, weak acids and alkalis, oils, saturated hydrocarbons, etc. Thanks to the above properties, products made from ASA materials always maintain their mechanical durability, color as well as beautiful glossy surface even when standing outdoors for long periods of time. However, ASA can be affected by esters, ethers, ketones and chlorinated hydrocarbons, which may be considered by the manufacturer.

ASA plastic is highly rated for durability and weather resistance

Here are some statistics about the properties of ASA plastic:

- Flexural Strength: 38.6 - 78.6 MPa.

- Flexural Modulus: 1,413 - 2,606 MPa.

- Glass Transition Temp: ≅ 112 °C.

- Heat Deflection Temp (1.8 MPa): ≅ 92 °C.

- Tensile Strength: 35.0 - 50.5 MPa.

- Tensile Modulus: 1,786 - 2,468 MPa.

- Elongation at Break: 25 to 40%

- Elongation at Yield: ≅ 5.01%

The fire resistance of ASA plastic can reach UL94HB level. During the burning process, ASA plastic will release a benzene and rubber smell.

Chemically, substances with quite similar properties to ASA include ABS and AES. Their corresponding rubber phases are poly butyl acrylate, butadiene/styrene copolymer, and ethylene/propylene copolymer, respectively. It is known that the lower the rubber content, the greater the durability and impact resistance of products made from ASA. Because of its co-extrusion properties, ASA can be suitable for co-extrusion with PVC and PC.

3. Methods of working with ASA plastic

3.1 3D printing with ASA plastic - process

Car rearview mirrors manufactured with ASA in 3D form

With the properties that ASA possesses, it is added to the list of materials that can be well adapted to the 3D printing process. During the 3D printing process with ASA materials, it is necessary to adjust the appropriate printing parameters to get the best results, such as part size and shape, machine temperature, printing speed, etc. According to research, the ideal extruder temperature is set between 240 degrees Celsius and 250 degrees Celsius, and the bed temperature is set between 90 degrees Celsius and 130 degrees Celsius. The recommended ideal printing speed is 50-90 mm per second. Another thing to note is that ASA resin must be dried and kept dry during the 3D printing process. When printing ASA plastic using the 3D printing method, a heating bed is required and the printing bed needs to be completely sealed to produce the best results. Before printing, ASA materials need to be carefully checked for data and parameters to be able to meet the appropriate processing process.

3.2 Injection molding with ASA plastic

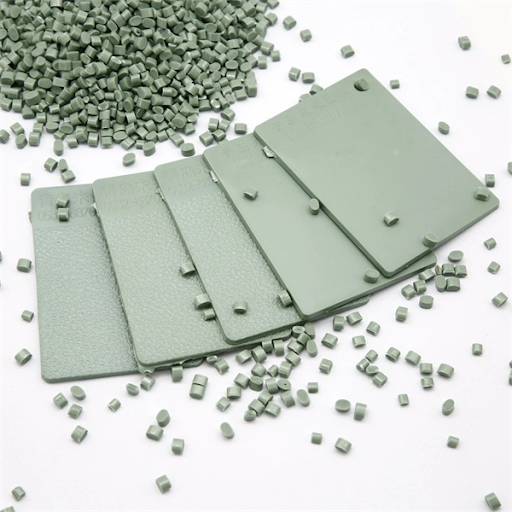

ASA plastic material is bright candidate for injection molding

In addition to 3D printing, ASA plastic material is also a bright candidate for injection molding. In this method, ASA plastic will go through the thermoplastic mixing process. Because ASA plastic alloy has a high gloss, the bed as a product does not require post-processing. Some typical properties that ASA injection molding brings include minimal creep, even at higher temperatures (up to 130 degrees Celsius), good toughness, even at low temperatures ( down to -100 degrees Celsius), heat and electrical insulation, weatherproof & UV resistant, high surface gloss, remarkable strength and stiffness, antibacterial etc.

According to the research proposed in the ASA injection molding process, to get the best results, you can refer to the following ASA plastic injection molding parameters for adjustment.

ASA injection molding parameters:

- Drying temperature (degrees Celsius): 80

- Drying time (hours): 3-4

- Mold temperature (degrees Celsius): 40~80

- Residual material (mm): 3~10

- Melting temperature(degree Celsius): 220~270

- Back pressure (MPa): 5~15

- Injection pressure (MPa): 70-120

- Screw speed (rpm): 50-90

- Shrinkage: 0.4%-0.7%

- Injection speed: Moderate

Read more: 3D printing vs Injection molding: Which way is appropriate?

3.3 Other methods work with ASA

In addition to injection molding and 3D printing, ASA resins can also be applied in manufacturing methods such as blow molding, welding, extrusion, structural foaming, thermoforming. etc.

4. ASA plastic application

ASA plastic application in automotive industry

Among plastic types, ASa plastic is at the top and is very famous for its excellent anti-ultraviolet (UV) radiation properties. In the automotive field, materials with this feature are also needed. ASA resin is an ideal choice for vehicle parts such as body parts, exterior chrome details, etc. Vehicle parts using ASa are always durable, impact resistant, weather resistant and always retain their shine and bright colors over the years.

Electrical and electronic applications tend to favor ASA plastic

- Applied electrical and electronics industry

Electrical and electronic applications tend to favor ASA because of its good insulation properties and high stability. Typical products made of ASA plastic can be mentioned as electrical casings, equipment connectors and other electrical product connection parts, etc. ASA plastic is a material that can ensure high safety, electrical insulation, and super durability, allowing these parts to operate for a long time while minimizing the possibility of damage.

ASA plastic withstands many different weather conditions

- Furniture and outdoor equipment

To become one of the optimal choices in the furniture and outdoor equipment industry, ASA possesses the ability to withstand many different weather conditions, even harsh weather. Products that use ASA plastic include outdoor furniture, backyard furniture, plant pots, and some garden decorations. These products promise stability over many years despite varying weather conditions. It meets the aesthetics of outdoor designs over a long period of use.

5. Conclusion

In short, ASA plastic is one of the materials with quite ideal technical specifications. This is also a type of plastic that can meet a variety of production techniques such as 3D printing, injection molding, welding, blow molding, etc. ASA plastic promises to bring your project timeless durability and high aesthetics over the years. To update more useful materials knowledge for your project, check out the useful blog articles at EuroPlas today!