Acetal vs Delrin certainly no longer strange to technical applications

The two names acetal vs delrin are certainly no longer strange to technical applications. Both acetal and Delrin are technical plastics. Besides possessing many similarities in properties, the two materials acetal vs delrin also bring their own unique advantages. It is difficult to choose if you put both acetal vs delrin the scale to compare, but choosing which material is more suitable is also based on many other aspects. In this article, let's learn more about the origin, outstanding characteristics, and specific applications of each type of acetal vs delrin plastic. The following information is truly an extremely useful tool for manufacturers to find answers to the differences between acetal vs delrin.

1. What is Acetal (POM) engineering plastic?

Acetal is essentially a semi-crystalline engineering thermoplastic

Acetal has the chemical structure R2C(OR')2 and is also known as polyoxymethylene (POM), polyacetal, polyformaldehyde, or polymethylene. This is an organic molecule whose bond consists of a single bond of two oxygen atoms to a central carbon atom (CH2O). Acetal is essentially a semi-crystalline engineering thermoplastic widely applied in many different types of production. Acetal has the ability to act like other metal materials, so it is used to replace many metal parts in production. In fact, applications made from acetal require high friction, dimensional stability, hardness and outstanding durability. Depending on production needs, investors make adjustments to the formula but the difference is insignificant.

2. What is Delrin engineering plastic?

Delrin resin is the trade name of acetal homogenizer

Delrin resin is essentially the trade name of acetal homogenizer. It is known by its full name as acetal Delrin(Polyoxymethylene POM). Because it is a homogeneous substance, it has a uniform framework that is also formed by repeating cyclic CH2O bonds. Delrin is also one of the engineering thermoplastics with the title of being the hardest and strongest reinforced material. In terms of properties, Delrin is also one of the perfect replacements for metal materials. Some outstanding features of Delrin such as abrasion resistance, creep resistance, warping resistance, and tensile strength are extremely ideal for engineering designs. Superior to other materials, Delrin also has advantages such as low moisture absorption ability, high hardness and wide temperature range that can operate in environments from - 40 to 120 degrees Celsius.

3. Overview on differences: Acetal vs Delrin

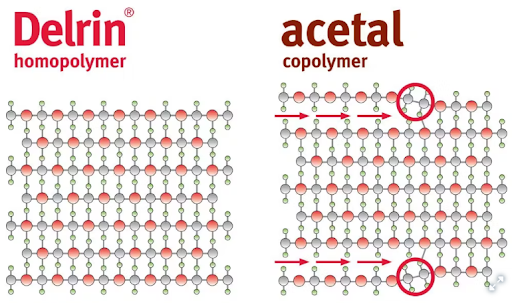

Acetal vs delrin possess their own unique characteristics

Overview of the differences between acetal vs delrin mainly in their molecular composition. We can briefly note that delrin material has a higher crystal structure order than acetal. The important thing that creates the difference in properties of each type lies in the connection between crystal regions. Depending on product needs and business purposes, the material production process can be adjusted in terms of the main ingredient ratio, so any improvements that help improve the bonds will make the material stronger. Because it possesses many crystalline regions, delrin has an advantage over acetal in terms of bond density between crystalline regions, thereby significantly improving the durability of the material.

Besides the structural similarities, acetal and delrin still possess their own unique characteristics that we can see below.

4. Properties comparison: Acetal vs Delrin

4.1 Properties of acetal

Acetal has a good resistance in both organic and inorganic acid environments

Acetal is considered an ideal material for many different technical applications because it possesses many advantages. Among them, it is necessary to mention the following outstanding properties of acetal

Acetal is a thermoplastic and is recyclable. The melting point of acetal is about 162 degrees Celsius to 175 degrees Celsius. Products made from acetal can be melted and recycled after use. Recycling is also an advantage that helps acetal be classified as an environmentally friendly material.

As mentioned above, acetal can withstand heat quite well up to nearly 160 degrees Celsius. In particular, thanks to its good heat resistance, acetal is less likely to degrade when exposed to heat. hot parts, hot water for a long time. This characteristic helps products made from acetal maintain dimensional stability in high temperature environments without losing their inherent mechanical properties.

The durability of acetal is partly due to its good resistance in both organic and inorganic acid environments or some other solvents.

Thanks to its low friction coefficient, acetal plastic is less susceptible to abrasion by external mechanical impacts.

Acetal can play the role of metals in many manufacturing applications thanks to their durability.

Acetal can be easily combined with reinforcing materials meaning they allow the molecules to bond with molecules from other materials (e.g. fiberglass). This gives acetal more opportunities to improve its properties significantly in terms of strength, toughness and hardness.

4.2 Properties of Delrin

Delrin possesses excellent properties of hardness, elasticity and strength

Delrin also possesses the ideal title for many technical applications no less than acetal. Some of these characteristics can be mentioned as follows

This characteristic is similar to acetal. The melting point of Delrin is about 120 degrees Celsius, the product can be recycled after use, bringing great benefits to the environment.

Delrin can be bent so it is often used in technical joints. The toughness of Delrin can be stable in the temperature range from - 40 degrees Celsius to 90 degrees Celsius.

Delrin's temperature range is quite wide between -40 degrees Celsius and 120 degrees Celsius. However, delrin's high temperature resistance cannot be maintained for a long time.

Technical applications that require parts to bear load for long periods of time and continuously often favor Delrin because they have very good fatigue resistance and rarely deform permanently.

Thanks to its high crystallinity, Delrin possesses excellent properties of hardness, elasticity and strength. Compared to acetal, Delrin has better mechanical properties.

When it reaches a certain melting point, Delrin can easily liquefy and fill the mold perfectly. Thanks to this feature, the mold placement process is accelerated and the production cycle is optimized.

Besides, Delrin also possesses some notable properties such as: high creep resistance, excellent impact resistance, high resistivity and high flexural modulus.

5. Application comparison : Acetal vs Delrin

5.1 Application of acetal

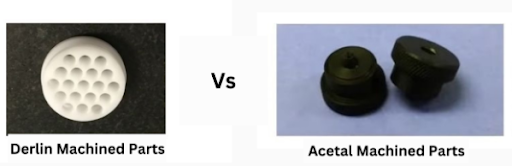

Acetal applications often favor designs of vehicle fuel tank

Acetal applications often favor designs that take full advantage of the chemical resistance of this material. Many investors have very well applied the advantages of acetal in a variety of applications, some of which can be mentioned as follows:

- Gear

- Pump

- Electric toothbrush

- Electrical connector

- Lock the door

- Kitchen utensils

- Fuel sending unit

- Insulin pen

- Dry powder inhaler

- Vehicle fuel tank

- Valve

5.2 Application of Delrin

Delrin application require high strength, stiffness, flexibility and tensile strength

Like acetal, delrin plastic is also optimally utilized for the strength and flexibility of this material in applications that require high strength, stiffness, flexibility and tensile strength. Many manufacturers are interested in delrin's excellent mechanical properties and have applied this material to designs such as the following

- Roller

- Implants & prosthetics

- Linear guide rails

- Conveyor system parts

- Safety restrictions

- Door system parts

- Zipper closure

- Bearings

6. Conclusion

In general, both acetal vs delrin materials are widely used in industrial and mechanical designs. From the above properties, it can be summarized that delrin is a superior choice for applications requiring durable, hard and flexible materials. Besides, acetal is a perfect choice for products that require chemical resistance and long-term exposure to solvents.

Acetal and Delrin are ideal engineering plastics for technical applications in human production life. To choose the appropriate type of plastic for each project, investors need to consider the unique characteristics of acetal vs Delrin as well as the needs of the product they are aiming for. Please visit EuroPlas's extremely useful sharing blog today so we can accompany you in your upcoming projects!