Plastic waste is a major environmental problem that affects our planet. To address this issue, many companies and researchers have been looking for ways to make plastic materials biodegradable. One of the solutions is to add a special type of additive to the plastic material that makes it easier to break down in the environment

In this blog, we will explore the different types of additives used to make plastic biodegradable, and the biodegradability testing methods used to measure their effectiveness.

Read more:

What are bioplastics made from? Materials to make bioplastics

What are plastic additives? 8 most common plastic additives in plastic industry

1. Common additive to make plastic biodegradable

1.1. Starch

Credit: Green Dot Bioplastics

Starch is a natural carbohydrate polymer that can be extracted from plants such as corn, wheat, and potatoes. It can be added as an additive to plastic to increase its biodegradability.

Characteristics: Starch-based plastics are easily broken down by microorganisms in the environment due to their natural origin. Starch can also improve the flexibility and toughness of the plastic material. However, starch-based plastics can be susceptible to moisture, which can affect their mechanical properties.

Advantages: The use of starch as an additive to make plastic biodegradable has several advantages. Firstly, it is a renewable resource that can be obtained from various plant sources, making it an eco-friendly alternative to traditional plastics. Secondly, starch is cost-effective and can be easily processed into a wide range of products, from packaging materials to utensils. Thirdly, starch-based plastics can reduce the negative impact of plastic waste on the environment.

Disadvantages: Despite its advantages, starch-based plastics have some limitations. They may not fully degrade in all environments and may require specific conditions, such as high temperatures and humidity, for biodegradation to occur. They may also have reduced strength and durability compared to traditional plastics, which can limit their use in some applications. Additionally, the use of starch as an additive can increase the cost of production, which may limit its adoption by manufacturers.

1.2. Bioaugmentation

Credit: EnviroZyme

Bioaugmentation is a process that involves adding microorganisms to plastic to enhance its biodegradation. The microorganisms can be naturally occurring or artificially introduced to plastic.

Characteristics: Bioaugmentation can improve the ability of plastic to break down in natural environments, such as landfills or composting facilities. The microorganisms consume the plastic, breaking it down into smaller molecules that can be absorbed by the environment. However, the effectiveness of bioaugmentation can be influenced by factors such as the type of plastic, the microbial community present in the environment, and the availability of nutrients.

Advantages: Bioaugmentation is a natural and sustainable solution to plastic waste. It can be used to biodegrade plastics that are not easily broken down, such as polyethylene. Furthermore, it can potentially accelerate the biodegradation process, reducing the time that plastic waste remains in the environment. Bioaugmentation can also enhance the overall biodegradability of plastics, making them more environmentally friendly.

Disadvantages: The effectiveness of bioaugmentation can be limited by several factors, such as the need for specific environmental conditions for microbial growth and activity. Bioaugmentation may also have potential negative effects on the environment if the introduced microorganisms compete with or displace the existing microbial community. Furthermore, the efficacy of bioaugmentation for large-scale plastic waste management requires further research and development.

1.3. Pro-oxidant additives

Credit: ACS Sustainable Chemistry & Engineering

Pro-oxidant additives are chemical compounds added to plastic to accelerate its degradation. They work by initiating an oxidation process that breaks down the plastic into smaller molecules that can be degraded by microorganisms.

Characteristics: Pro-oxidant additives can increase the biodegradability of plastics, making them more environmentally friendly. They are also cost-effective and can be added to a wide range of plastic materials. However, the effectiveness of pro-oxidant additives can vary depending on the type of plastic, the dosage and application method of the additive, and the environmental conditions.

Advantages: The use of pro-oxidant additives has several advantages. Firstly, they can reduce the time that plastic waste remains in the environment, potentially reducing the negative impact of plastic waste on the ecosystem. Secondly, pro-oxidant additives can be easily incorporated into existing plastic production processes, making it a feasible option for manufacturers to produce biodegradable plastic products. Thirdly, they are cost-effective and can be applied to a wide range of plastic materials.

Disadvantages: The effectiveness of pro-oxidant additives can be limited by factors such as the need for specific environmental conditions for degradation, the potential release of toxic additives during degradation, and the potential for incomplete degradation, which can lead to microplastics. Furthermore, the use of pro-oxidant additives may not address the root cause of plastic waste generation, which is the overuse and improper disposal of plastic materials.

2. Biodegradability testing for plastic

Credit: BioCycle

In order to determine the effectiveness of additives to make plastic biodegradable, it is important to conduct biodegradability testing which is a process that measures the ability of plastic to break down in natural environments.

There are several methods used to test the biodegradability of plastic, each with its own set of advantages and disadvantages. In this section, we will explore how to test the biodegradability of plastic with these different techniques.

ASTM D5511 – 18

Definition: ASTM D5511-18 is a standardized test technique for determining the anaerobic biodegradability of plastic materials in circumstances of high-solids anaerobic digestion. The test analyzes the quantity of biogas produced during the anaerobic digestion process, which is used to determine the biodegradability of the plastic.

Procedure: The test is carried out by introducing a plastic sample, an inoculum containing anaerobic microbes, and sludge to a sealed tank that replicates landfill conditions. The tank is then incubated at a certain temperature and monitored over time to determine the quantity of biogas generated. The biogas produced during the test may be examined to determine the methane concentration and rate of biodegradation.

Application: This test is especially pertinent for analyzing plastics that are intended to be disposed of in anaerobic conditions such as landfills.

ASTM D5526 – 12

Definition: ASTM D5526-12 is a standardized test technique for assessing aerobic biodegradation of plastic compounds in soil. By measuring carbon dioxide evolution during the degradation process, the test determines the degree and rate of biodegradation.

Procedure: The procedure involves burying plastic samples in soil and monitoring the carbon dioxide levels generated by the soil on a regular basis. The amount of carbon dioxide exhaled indicates the rate of biodegradation of the plastic. Depending on the required duration of the trial, the test is often carried out over many months or even years.

Application: The method is useful for evaluating the biodegradability of plastics that may end up in soil environments, such as agricultural mulch films or compostable packaging.

ASTM D5209-92

Definition: The ASTM D5209-92 test technique is a standardized test method for evaluating the aerobic biodegradation of plastic materials in a controlled composting environment. The test monitors carbon dioxide evolution and changes in the physical and chemical characteristics of the plastic during the composting process to determine the degree and pace of biodegradation.

Procedure: Plastic samples are tested in a controlled composting setting that mimics the characteristics of industrial composting plants. Temperature, moisture, and oxygen levels are monitored during the composting process to ensure that the conditions stay appropriate for biodegradation. The plastic samples are removed and analyzed on a regular basis for changes in weight, molecular weight, and chemical composition.

Application: ASTM D5209-92 is useful for evaluating the biodegradability of plastics that may end up in composting facilities, such as food service items or packaging materials.

ASTM D6003-96

Definition: ASTM D6003-96 is a standardized test method used to evaluate the biodegradation of plastic materials in soil. The test measures the degree and rate of biodegradation by monitoring the evolution of carbon dioxide and changes in the physical and chemical properties of the plastic during soil burial.

Procedure: To conduct this test, plastic samples are buried in soil at a controlled temperature and moisture level. The soil is periodically aerated to maintain the appropriate oxygen levels for biodegradation. The plastic samples are then excavated at regular intervals and analyzed for changes in weight, molecular weight, and chemical composition.

Application: This testing method is best for evaluating the biodegradability of plastics that may end up in soil, such as agricultural films, mulch films, and other soil-contact applications.

ASTM D5338 – 98e1

Definition: ASTM D5338 – 98e1 is a test method for determining the aerobic biodegradation of plastic materials under controlled composting conditions. This standard test method provides a procedure for measuring the degree and rate of biodegradation of plastic materials in a simulated aerobic composting environment.

Procedure: The evaluation is carried out by exposing the plastic material to a controlled composting environment for a predetermined amount of time after being inoculated with a mixed culture of microorganisms. Measured carbon dioxide (CO2) is evolved throughout the biodegradation process, and the amount of CO2 evolved is used to compute the rate of biodegradation.

Application: This test technique is highly suitable for determining the biodegradability of plastic materials intended for composting in a commercial composting facility. It is often used to assess the biodegradability of plastic mulch films, food packaging, and agricultural films.

ASTM D6400 – 12

Definition: ASTM D5338-98e1 is a standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions. This method evaluates the ability of plastic materials to be bio-degraded by microorganisms in the presence of air and moisture.

Procedure: In this test, a sample of the plastic material is placed in a controlled composting environment, which includes temperature, humidity, and oxygen conditions similar to those found in a municipal composting facility. The sample is periodically removed and analyzed for its biodegradation rate, as well as for any changes in physical or chemical properties.

Application: This test is useful for evaluating the potential biodegradability of plastic materials

in composting environments, such as those found in municipal waste facilities. It can help determine if a plastic material is suitable for disposal in these facilities or if it will persist in the environment for an extended period of time.

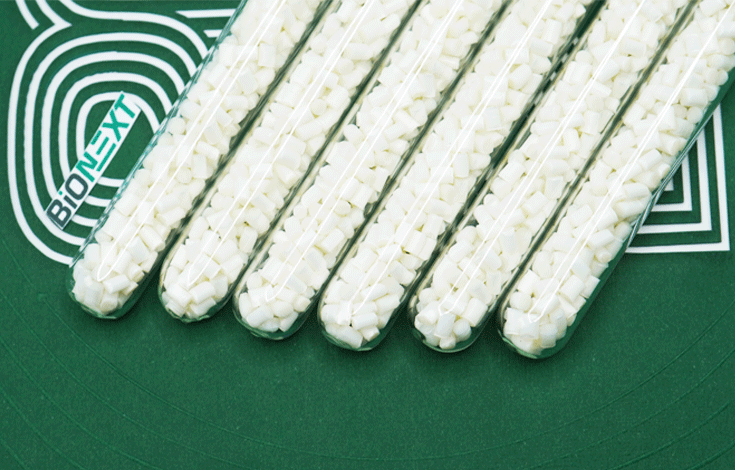

BiONext is a totally degradable plastic additive developed by EuroPlas, a leading masterbatch manufacturer in Vietnam with over 15 years of experience. BiONext is a unique blend of biodegradable polymers and proprietary additives that enable conventional plastic products to degrade in a landfill environment.

BiONext is also non-toxic and does not release harmful residues during degradation. It is an ideal solution for companies that want to transit to sustainable practices while still using traditional plastic products. It is a cost-effective and practical alternative to other totally degradable plastic additives that require new manufacturing processes and infrastructure. With BiONext, companies can reduce their carbon footprint and contribute to the global effort to reduce plastic waste and pollution.

So if you are looking for totally degradable plastic additives to work on your next products, please contact us for more information.