Nonwoven materials are not textiles, but they are very important for us. These materials are formed by classification of fibers through chemical or thermal bonding. The choice of plastics to be used as fibers is crucial since it determines the functions targeted in the output nonwoven cloth.

1. A List Of Plastics Used To Make Nonwoven Fabrics

Different considerations must be made when picking out a specific type of plastic which include desired attributes, purpose and level of performance required at the end product development stage. Here are types of plastic used in nonwoven fabrics manufacture.

1.1. Polypropylene (PP)

Among all types of plastics that could be incorporated into nonwoven fabrics, Polypropylene (PP) still dominates. This plastic is known to have higher strength, durability and are chemically resistant to most solvents. Polypropylene nonwovens are utilized in filtration, personal care sectors, and automotive industries.

Read more: Producing nonwoven fabrics with PP filler masterbatch

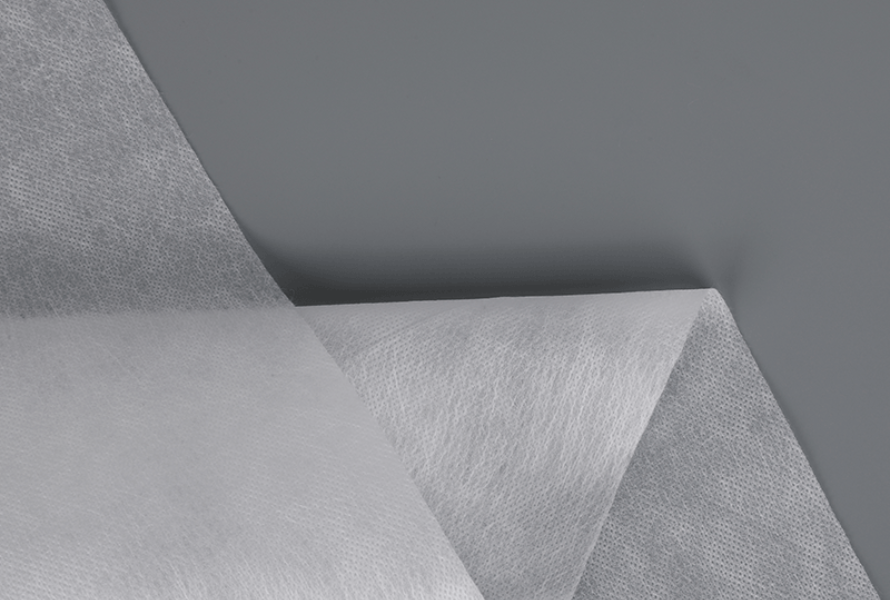

Polypropylene is one of the most widely used plastics for nonwoven fabrics.

1.2. Polyethylene (PE)

Polyethylene is one more of the plastics that are used in the making of nonwoven fabric. The fabric has a softness and absorbency that make it ideal for keeping things clean. In addition, its barrier may be used to provide sanitary protection. This fabric is used in a variety of commercial hygiene and cleaning products.

1.3. Polyester (PET)

Polyester is commonly used in filter applications and in bandages. This is due to its strength and chemical and thermal stability. Polyester's nonwoven fabrics are often featured in industrial filters or automotive applications.

Polyester is a versatile plastic that can be used to create nonwoven fabrics.

1.4. Nylon (PA)

Nylon is another synthetic polymer utilized for making nonwoven fabrics because of its benefits like strength, abrasion, and heat resistance. Mainly, nylon nonwovens are applied in industries with other usage areas out there such as recreational clothing and seamless clothing too.

1.5. Polyurethane (PU)

Polyurethane is a kind of plastic that can be used to produce nonwoven products with good buoyancy, flexibility and chemical resistance to oil and chemicals. Polyurethane nonwoven products are utilized in furniture, automobile seatings, and protective apparel.

1.6. Biobased plastics

Recently, researchers and industries have shown interest in using bioplastics including PLA and PHA for producing nonwoven materials. There are more ecological and bio-degradable bioplastics than the conventional plastic materials that are manufactured from petroleum products.

2. Advantages and Disadvantages of Nonwoven Fabrics

2.1. Advantages of Nonwoven Fabrics

Nonwoven fabrics are a novelty and multifunctional textile material that has great market demand in different fields. These fabrics are made using techniques that are distinct from the more generic woven or knitted categorizations; these technical fabrics contain a range of characteristics as per the requirements of various application domains of the modern world.

Some of the key advantages of nonwoven fabrics that contribute to their growing popularity include:

- Cost-effectiveness: Nonwoven fabrics can also be manufactured at a lower cost than woven or knitted fabrics since the production method is different and relatively easy.

- Versatility: Nonwovens can thus be made with desired characteristics such as high tensile strength softness or absorbency filtration efficiency thermal/acoustic insulation etc to suit the intended application.

- Customizability: It is possible to achieve the properties required in a specific application since one can modify the fibers, structure, and bonding methods of the nonwoven fabric.

- Efficient production: Other manufacturing techniques like spun bonding or melt blowing enable higher productivity and a more continuous way of producing the nonwovens than most textile technologies.

- Material utilization: Nonwoven production can help reduce wastages, and ensure that the raw material is fully utilized in the fact that the fibers are processed directly into the required fabric network.

- High functionality: Nonwovens’ properties allow for the influence of their performance characteristics, and products with specific purposes can be designed for the appropriate application.

Read more: Using nonwovens in packaging is great for your business

Nonwoven fabrics are a popular choice across various industries thanks to having many benefits.

2.2. Disadvantages of Nonwoven Fabrics

Overall, it can be seen that nonwoven fabrics have even more benefits, but need to consider their disadvantages in choosing the best type of textile for certain needs and purposes. Here are the disadvantages of nonwoven fabrics:

- Limited durability: Compared with the manufacture of woven or knitted fabrics, nonwoven fabric could cause lower tear strength as well as abrasion resistance if the procedure and type of raw material are used.

- Potential for defects: Since nonwoven manufacturing is a continuous production process, there is a greater potential of entailing some low-quality attributes like holes, thickness non-uniformity, and impurities in case of non-proper control.

- Difficulty in recycling: The complexity of some nonwoven fabrics, including having more than one layer and made up of more than one material, makes the recycling of the nonwoven fabrics to be challenging as opposed to the single-material fabrics.

- Limited dimensional stability: Nonwoven fabrics commonly have a higher degree of shrinkage or elongation than woven or knit fabrics especially when the material is exposed to heat, water or pressure.

- Potential for static buildup: It bears mentioning that static electricity is usually associated with the nonwoven fabric because of the type of polymer used and the creation of the fabric structure.

- Limited aesthetic appeal: Nonwoven fabrics are also not as smooth, very flexible and have as good looks as normal woven fabrics; this is a disadvantage particularly when the fabric is intended for clothing or fashion.

While nonwoven fabrics offer numerous advantages, it is essential to consider their potential drawbacks and limitations.

3. Conclusion

Nonwoven fabrics are useful in multiple applications, but it is equally important to understand the drawbacks of this material in order to arrive at an informed conclusion. The choice of plastic raw materials in making nonwoven fabrics depends on the application of the fabric it is to serve, with regard to strength, chemical inertness, water absorbency, and price. Of them, polypropylene is the type of plastic most commonly used in the production process as a result of its high degree of hardness.

4. About EuroPlas

Today, if you are seeking polypropylene (PP) to be used in making nonwoven fabrics, then you can rely on EuroPlas. We offer the best PP material, not only in quality but in performance as well, guaranteeing your satisfaction.

Kindly contact us for further assistance and to get detailed consultation.