The nonwoven packaging sector has been thriving since single-use packaging was accused of a driver behind environmental pollution. Nonwoven packaging is changing people's habits towards environment-friendly products.

Before that, it has been neglected, not counted as a part of nonwoven applications. For two decades, nonwovens have been in a great development process in the packaging industry. Now, it is still growing.

After over 25 years, the sector has been mature, but still remains promising and expanding. Because disposable packaging use is limited in some countries and many other countries will follow this policy.

The position of nonwovens used in the packaging sector is changing. Nonwoven packaging is dominating part of the market as its applications now make up approximately 3 percent of all nonwoven applications.

The favor of end uses for nonwovens in packing is spread and also large. Besides, new applications and developments are regularly updated as the materials become more well-known by the community and society.

Top 5 well-known and largest application sectors of nonwovens are:

The most significant developing area for nonwovens is the retail shopping bag market. The main reasons for this growth are a combination of media campaigns, changes in customer attitudes, and improved performance.

The single-use bag sector has seen a remarkable decline as customer awareness of the environment is increasing, and they prefer durable multi-trip bags over single-use shopping bags.

Promotional nonwoven bags have been used in a lot of formats in almost every exhibition and promotional event.

The advantages of promotional nonwoven bags are lightness and strength. They can pack heavier items compared to any type of bag, they are light as single-use bags and easy to carry. Moreover, they look great and can deliver promotional messages to customers for extended periods.

Nonwoven packaging is easy to print and easy to design. Great design can create all new markets. One of the most well-known and interesting nonwoven packaging products has been the “Clever Little Bag” of Puma.

Puma as a leader in sports products creates product packaging that is not easy to carry out, they have a whole team and system to do that. It took almost 21 months to seek alternatives to traditional shoeboxes, and finally, a ‘clever little bag’ used nonwovens.

“The nonwoven bag uses 65% less cardboard than the standard shoe box, has no laminated printing, no tissue paper, takes up less space, and weighs less in shipping and replaces the plastic retail bag” said Kellie.

Packing can be used as a marketing tool for companies to promote the company image and products. A picture says a thousand words. Packaging delivers the message about product information and characteristics in a smart way. Different groups of people have different ways to express ideas through packaging.

Factors that affect Consumer Buying Behaviour by Packaging:

Proper packaging of the product is essential to attract consumers. The appearance of packaging definitely helps consumers to identify the product brand. Every different element of packaging attracts the consumer’s attention.

However, there is one thing producers should keep in mind. The material used for packaging also plays an important role in a customer's buying decision as customers now become very aware and educated.

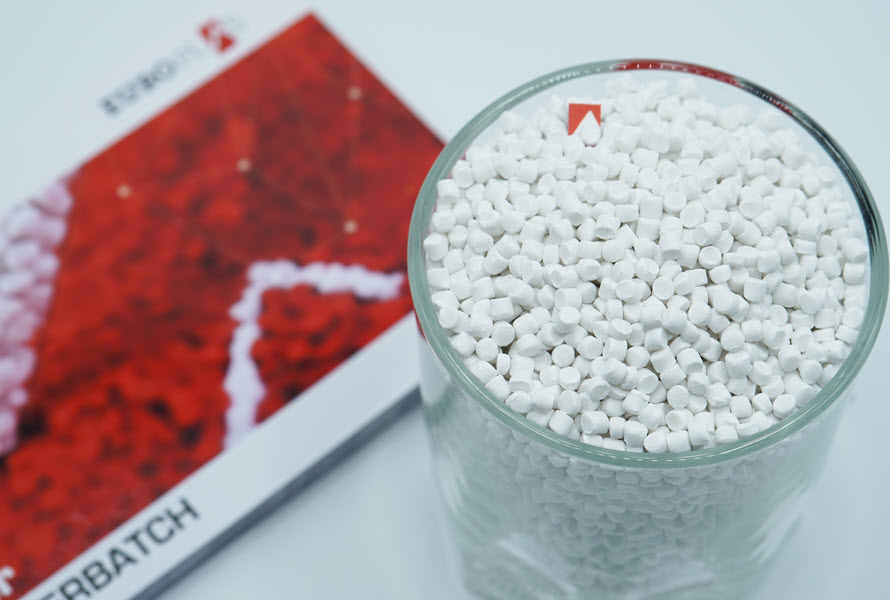

Filler masterbatch is an added ingredient in the production of non-woven fabrics because of the following advantages:

- Save production cost

- Improve several properties of end-products: brightness, opacity, shrinkage reduction,...

- Save energy thanks to CaCO3's great thermal transmission ability

Increase the stability in the manufacturing process, thus shortening the production cycle

For more detailed information and choosing the right filler masterbatch for your product, please

contact our sales team.