Electrostatic is a common phenomenon when using plastic products. If not fixed, electrostatic will cause consequences related to the safety of users and product quality. So what is electrostatic? How to minimize the harmful effects of electrostatic phenomena on plastic materials? Let’s find out about this topic right here.

Read more: What are plastic additives? 8 most common plastic additives in plastic industry

1. Electrostatic

1.1. What is electrostatic?

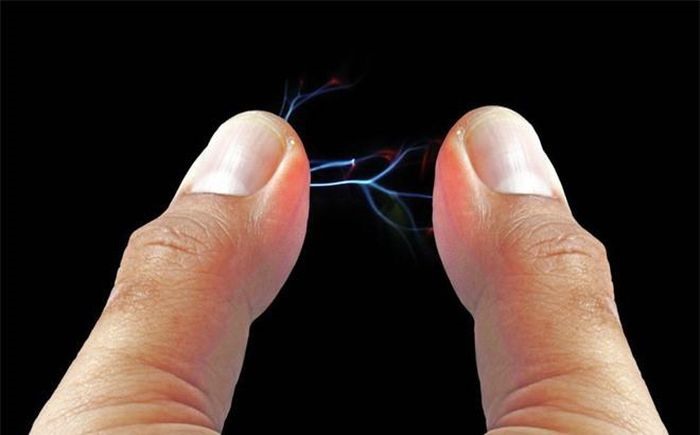

Electrostatic is the phenomenon of an insomnia on the surface of a material. The charge will survive and accumulate a large amount until it can transmit or discharge. Materials such as plastic, leather, etc. are often highly electrostatic. Electric charge will cause consequences:

Industry:

- Dust

- The packaging sticks to each other or sticks to other objects

- Shockwave

- Electrical rays damage electronic circuit boards and small and micro-electrical equipment

- Electric rays can cause a fire in places that easily caught fire.

Life:

- Dust clinging to the surface of the device has friction with the air such as the rotor; Devices with heat generation such as TV, causing inconvenience when hygienic and living.

- Electric shock, electric rays can cause fire. In fact, there are many cases of fire and explosion at petrol stations due to electric sparks due to electrostatic, the cause is often accidentally rubbing raincoats, sweaters, leather items, ...

1.2. Causes of electrostatic

When we step on the carpet, brush the fabric on the table, the chair surface, rubbing hair together, rotating rotor, the dried wind blowing strongly, ... then we are creating friction. The two insulating surfaces are friction or repetitive changes, exposure to ionized gas will generate electrostatic charges, one side of the negative, and one side of the positive.

Most plastic materials are insulated (resistors are usually greater than 1012OHM). You can refer to the insulation parameters of the plastic types:

|

Plastic

|

Insulation (Ohm/sqrs)

|

|

ABS

|

10^12

|

|

PA 6

|

10^15

|

|

PA 6 (ẩm)

|

10^12

|

|

PC

|

10^16

|

|

PE

|

10^17

|

|

PP

|

10^19

|

|

PS

|

10^17

|

2. Antistatic solution for plastic

Because electrostatic phenomenon can occur during processing or during the use of the product, we can divide it into two treatment methods. For anti-static processing, manufacturers can use antistatic devices or use products to relieve electricity in processing. And to avoid the electrostatic phenomenon for users, we can mix anti-static additives into the ingredients of production.

|

Methods

|

Pros

|

Cons

|

|

Use the device

(Electrostatic removal bar, anti-static nozzle, antistatic guns, gas knives, ...)

|

Long use time;

Regardless of the environment;

Anti-static and ensure safety during production.

|

Investment costs and installation are quite high.

Do not apply in the process of using the last product.

|

|

Use additives

(Used in protective equipment, coverage, wrap, ...)

|

Easy to use;

Low cost;

Flexible;

Anti-static during processing and using products.

|

Greatly affected by environmental factors;

Usage time is less than 1 year.

|

Thus, it can be seen that the use of antistatic additives is currently a method to save costs and bring high efficiency.

3. Common types of antistatic additives

Antistatic additives will be divided into 2 types: moving antistatic additives and not moving antistatic additives. The table below will explain the method of operation and the advantages and disadvantages of each type.

|

Moving antistatic additives

|

Not moving antistatic additives

|

|

Working mechanism

|

A surfactant substance, one end capable of associating with plastic background, one end capable of absorbing moisture in the air

|

Work as a part of the network of the material

Formation of the electric pathway in materials

|

|

The type of substance used

|

Anionic, Cationic, Amphoteric, Nonionic, ...

|

Nonionic, inorganic substances, polymer, carbon black, ...

|

|

Pros

|

Low use content

Easy to use

|

Long-lasting

Effective use is less affected by the environment

|

|

Cons

|

Short use time

Operating efficiency depends on environmental conditions (moisture and temperature)

|

The content used in the end product is high

|

4. EuP anti-static additive products

EUP provides 2 groups of antistatic additive products including antistatic products (108 - 1012 Ohm) and static and dust-proof products. These products have the following characteristics:

- Effective with low content in the final product;

- Mechanical effects, color

- Environmental friendliness

- Effective throughout the life cycle of the product.

|

Group

|

Grade

|

Content (%)

|

Suitable for

|

Applications

|

|

Antistatic

|

EM EDS 2050

|

2-7%

|

PE, PP

|

Films, bottles, Injection molding

|

|

EM EDS 2051

|

2-7%

|

ABS, PS

|

Extruding sheet or injection molding

|

|

EM EDS 2052

|

2-5%

|

PVC, PS

|

Curtains, films

|

|

Power release

|

EM EDS 106

|

3-7%

|

PE, PP

|

Films, bottles, Injection molding

|

If you want to know more about our products, please fill in this form or contact us via email/phone number. We are very happy to help!