Corn vs. Sweet Potato Bioplastic: Which is Better for Bioplastic Production?

As the world shifts away from fossil-based plastics, bioplastics have emerged as a sustainable solution. Among the numerous sources of bioplastic, corn and sweet potato bioplastic stand out due to their abundance and renewability. But which one is truly better for large-scale bioplastic production?

In this article, we explore the characteristics, advantages, and limitations of bioplastics made from corn and sweet potato, comparing them across sustainability, performance, production efficiency, and market potential.

1. What is Bioplastic?

Bioplastic is a type of plastic derived from renewable biomass sources such as corn starch, sweet potato starch, sugarcane, and cellulose. Unlike conventional plastic, which is petroleum-based, bioplastic aims to reduce carbon footprint and environmental harm.

There are two main categories:

- Bio-based bioplastic: Derived from plant material (like PLA from corn or sweet potatoes)

- Biodegradable bioplastic: Designed to decompose under certain environmental conditions

Many products, such as packaging films, food containers, straws, and agricultural films, are increasingly made using bioplastic.

Corn vs. Sweet Potato Bioplastic

2. Overview of Corn-Based Bioplastic

Corn-based bioplastic, primarily in the form of PLA (polylactic acid), is the most widely used bio-based plastic today.

2.1. Raw Material & Production

Corn starch is fermented into lactic acid, which is then polymerized to form PLA. This process is relatively efficient due to the global abundance of corn and established supply chains.

EuroPlas' BiONext 400 is a type of corn-based bioplastic

2.2. Advantages

- Large-scale infrastructure already exists for corn PLA

- Relatively low cost

- Biodegradable under industrial composting conditions

- Clear and rigid, ideal for food packaging

2.3. Limitations

- Requires high-temperature composting facilities to degrade

- Derived mostly from food-grade corn, raising food vs. material concerns

- Potential dependency on genetically modified crops

3. Overview of Sweet Potato Bioplastic

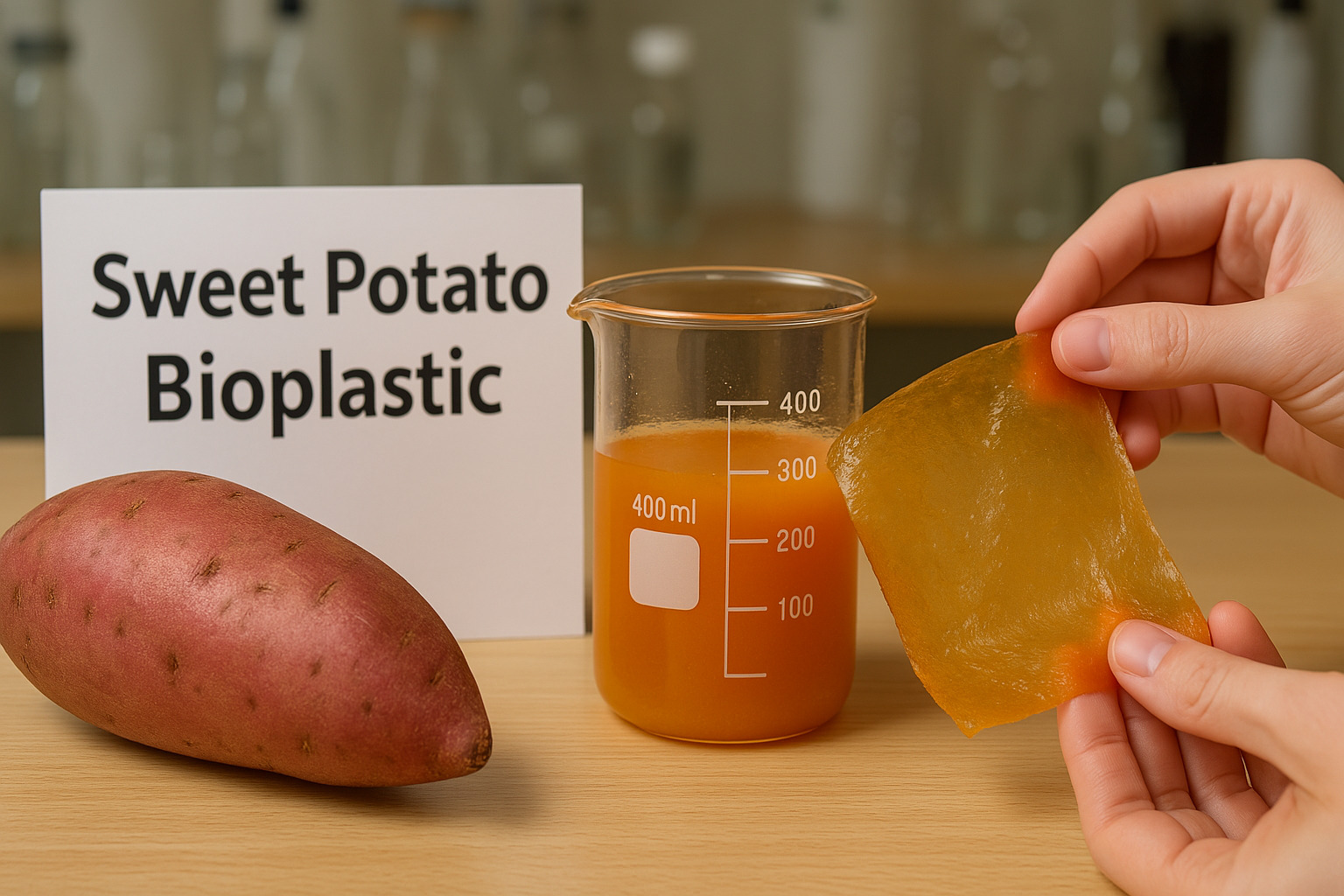

Sweet potato bioplastic is an emerging innovation in sustainable materials, particularly in countries with surplus sweet potato production.

3.1. Raw Material & Production

Sweet potatoes are high in starch, which makes them suitable for bioplastic production. The process involves extracting starch, converting it into glucose, fermenting it into lactic acid, and polymerizing it into PLA or thermoplastic starch (TPS).

Sweet potato bioplastic is an emerging innovation in sustainable materials

3.2. Advantages

- Sweet potatoes grow quickly and require less fertilizer than corn

- Higher starch yield per hectare compared to corn

- Adaptable to marginal lands not ideal for conventional agriculture

- Suitable for both PLA and TPS bioplastics

3.3. Limitations

- Less industrial infrastructure currently available

- Still in early research and development stages

- Regional production limited to specific climates and economies

4. Sustainability Comparison

4.1. Land and Water Usage

Sweet potato bioplastic has a potential advantage. Sweet potatoes typically need less water and fertilizer, and can grow in less fertile soils. Corn, while widely cultivated, requires intensive farming, irrigation, and pesticide use, which impacts soil and water ecosystems.

4.2. Carbon Footprint

Both sweet potato and corn bioplastics offer reduced greenhouse gas emissions compared to petroleum-based plastics. However, sweet potato’s faster growth cycle and fewer inputs can result in a lower net carbon footprint, particularly in regions with high productivity.

4.3. Food Security Impact

Corn bioplastic relies on a major food crop. Using it for industrial materials can drive up food prices and raise ethical concerns. Sweet potato bioplastic, especially when using non-edible or surplus varieties, may pose less threat to food security.

5. Material Performance

5.1. Mechanical Strength & Durability

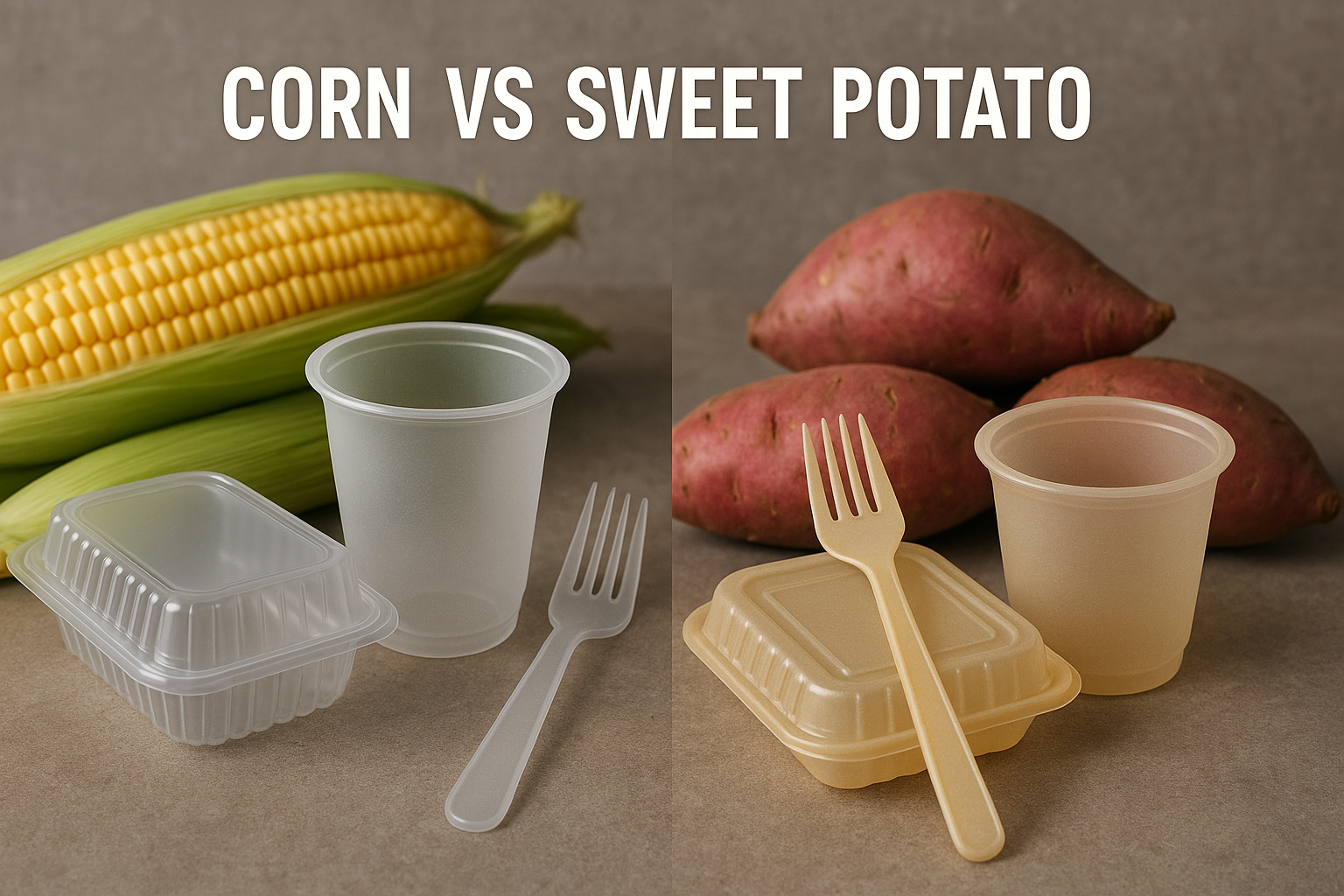

Corn-based PLA is known for good clarity, rigidity, and tensile strength, making it ideal for packaging.

Sweet potato bioplastic, particularly when formulated as thermoplastic starch, can be more flexible but less mechanically strong. However, research shows that blending it with other biopolymers or additives can enhance its performance.

5.2. Biodegradability

Both materials are compostable under industrial conditions. Thermoplastic starch from sweet potatoes can degrade more quickly under natural conditions compared to PLA, depending on formulation.

Research shows that blending sweet potato bioplastic with other biopolymers or additives can enhance its performance.

6. Economic and Market Viability

6.1. Availability and Supply Chain

Corn benefits from global cultivation, large-scale harvesting equipment, and industrial fermentation facilities. Its production is mature, making corn bioplastic more commercially viable at scale.

Sweet potato bioplastic currently lacks large-scale infrastructure but holds potential in regions with sweet potato surplus, such as Southeast Asia and parts of Africa.

6.2. Research and Innovation

Sweet potato bioplastic is still in development. Researchers in countries like Japan, China, and Vietnam are exploring its commercial potential. With proper investment, it could become a regional alternative to corn PLA.

7. Environmental Considerations

7.1. End-of-Life and Waste Management

Neither PLA nor sweet potato-based bioplastic decomposes effectively in home compost. Industrial composting is necessary. However, thermoplastic starch from sweet potato may degrade more rapidly in soil or aquatic environments.

7.2. Recycling

PLA from corn can contaminate traditional plastic recycling streams. Similarly, sweet potato bioplastic may not be compatible with current recycling systems unless properly labeled and sorted.

8. Which is Better for the Future?

Corn-based bioplastic is proven, scalable, and already commercially viable. It’s the go-to choice for businesses needing sustainable packaging today.

Sweet potato bioplastic, on the other hand, holds great potential for future growth. Its sustainability profile, higher starch yield, and adaptability make it promising for decentralized or regional bioplastic production, especially in countries with limited corn access.

In the long term, investment in sweet potato-based technologies could diversify bioplastic sources and reduce pressure on global corn supplies.

Choosing between corn and sweet potato bioplastic depends on your priorities

9. Conclusion

Choosing between corn and sweet potato bioplastic depends on your priorities: short-term scalability or long-term sustainability. Corn-based PLA is market-ready with existing infrastructure, while sweet potato bioplastic is an emerging star with impressive ecological advantages.

For countries seeking to develop local bioplastic solutions using sustainable and non-competitive crops, sweet potato might be the better answer. As research progresses and technology improves, sweet potato bioplastic could shift from alternative to mainstream.

10. About EuroPlas

EuroPlas is one of the global leaders in the field of bioplastic compounds and filler masterbatches. With a strong focus on sustainable innovation, EuroPlas develops advanced bioplastic solutions including BioNext and BioMates, tailored for packaging, agriculture, and consumer goods.

Explore more at: https://europlas.com.vn