This article is an all-inclusive copolymer guide for those who want to know more about copolymers. We will give you a thorough explanation of copolymers, its types and its crucial function in the material engineering context. You will learn about the practical uses of copolymers, highlighting their significance in the fields of materials science and engineering. Hesitate no more but scroll down right now!

1. What is a copolymer?

A copolymer is a polymer made up of two or more monomer species. During the copolymerization process, several monomers are mixed to produce a polymer with unique properties that do not present in the individual monomers. The resulting copolymer may be used to tailor the properties of a wide range of materials.

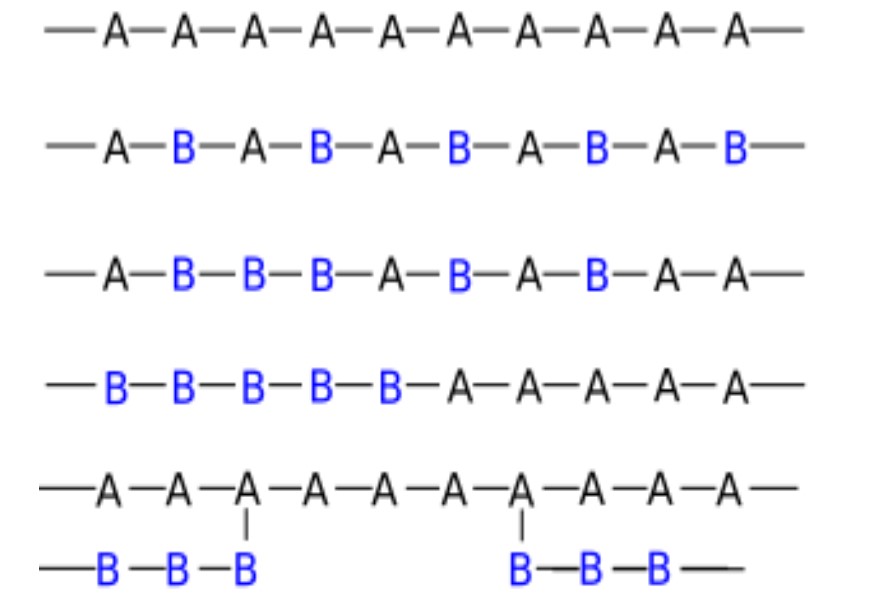

Copolymers can have a wide range of forms depending on how the various monomer species are ordered in the polymer chain. Block copolymers are composed of two or more homopolymers linked to create a single chain. Two instances of exact orderings for the homopolymer units are A-B-A and A-B-C. On the other hand, monomers are randomly linked together in random copolymers, regardless of the sequence or positioning of the links. In alternating copolymers, the monomer species in the polymer chain alternate on a regular basis.

Here are a few examples of the copolymers: Nitrile rubber, Polyethylene-vinyl acetate (PEVA) and Acrylonitrile butadiene styrene (ABS).

2. Types of copolymers

2.1. Linear copolymers

Statistical and alternating copolymers are two further categories into which linear copolymers are divided. The way the monomers are arranged on the main chain serves as the basis for this categorization.

2.1.1. Block copolymers

- A block copolymer is a single-chain macromolecule created when many homopolymer units are joined by covalent bonds.

- An intermediary unit where the two homopolymer chains are connected is called a junction block.

- Whereas a triblock copolymer has three different homopolymer blocks, a diblock copolymer only has two homopolymer units.

- Acrylonitrile butadiene styrene, or SBS rubber, is one example of such a polymer.

2.1.2. Statistical copolymer

- Polymers in which two or more monomers are organized in a sequence that complies with a statistical criterion are known as statistical copolymers.

- The whole polymer is referred to as a random polymer if the mole fraction of each monomer equals the probability of discovering a residue of that monomer at any point in the chain.

- Generally speaking, the free radical polymerization process is used to create these polymers.

- Rubber derived from styrene and butadiene copolymers is an example of a statistical polymer.

2.1.3. Alternating copolymers

- A single main chain with alternating monomers make up alternating copolymers.

- (-A-B-)n is a generalization of the formula of an alternating copolymer composed of monomers A and B.

- An example of an alternating copolymer is nylon 6,6, which is made up of alternating units of adipic acid and hexamethylenediamine.

2.1.4. Periodic copolymers

These polymers include a single chain of monomers organized in a repeating pattern.

2.1.5. Gradient and stereoblock copolymers

Gradient copolymers are single-chain copolymers in which the main chain's monomer makeup progressively changes. The macromolecule is referred to as a stereoblock copolymer if the tactility of the monomers differs with various blocks or units in the polymer.

2.2. Branched copolymers

A branched copolymer, as its name implies, is a polymer in which the monomers arrange themselves into a branching structure. Star, comb, grafted, and brush copolymers are a few significant varieties of branched copolymers.

- Star copolymers: Multiple polymeric chains joined to a single central core make up a star copolymer.

- Graft copolymers: They are branched copolymers with side and main chains that have distinct structures.

3. The role of copolymers in industries

3.1. Valuable properties

First, let’s explore what determines the properties of this material! Different types of copolymers have slightly different properties, depending on the composition, ratio, and arrangement of the monomers. These factors can be precisely controlled throughout the polymerization process to produce materials with customized properties for a range of industrial uses.

- The nature of monomers: Choosing particular monomers might affect the final copolymer's characteristics. Some might improve the material's resistance to impact or chemical deterioration, while others would improve its thermal stability.

- The order of monomers: The copolymer's properties are influenced by the arrangement of its monomers, which can be arranged in an alternating sequence, periodic clusters, or a random assortment.

- The proportion of monomers: Engineers can further modify the qualities of a material by adjusting the monomer ratio. For example, raising the amount of a certain monomer may increase the flexibility or resilience of the resulting copolymer to specific environmental conditions.

Here are the outstanding properties of copolymers allowing it to be used in many industrial sectors:

- Customizable: In contrast to homopolymers, copolymers provide the possibility of modifying the material's qualities due to the variety of their monomers. For example, one may modify optical characteristics, conductivity, elasticity, and hardness to suit one's needs.

- Enhanced compatibility: Incompatibility is a common problem for several homopolymer types in polymer blends. By functioning as compatibilizers, copolymers can reduce these problems and improve the overall performance of the mixture.

- Access to advanced applications: Copolymers' versatility makes them suitable for advanced applications, including drug delivery nanoparticles, fuel cell membranes, additive manufacturing enhancers, etc.

3.2. Applications

Even though their existence is sometimes ignored, different types of copolymers have merged perfectly into everyday life. Copolymers can be found in a wide range of products, from the cushiony texture of your shampoo bottle to the sturdy sole of your rubber shoes. Here's a brief list for your reference:

Even though their existence is sometimes ignored, different types of copolymers have merged perfectly into everyday life. Copolymers can be found in a wide range of products, from the cushiony texture of your shampoo bottle to the sturdy sole of your rubber shoes. Here's a brief list for your reference:

- Automotive Sector: There are several uses of copolymers in the automotive sector, ranging from rubber gaskets that ensure engine performance and stability to the usage of ABS (Acrylonitrile Butadiene Styrene) for strong automobile exteriors.

- Consumer Goods: Copolymers are used to make the surfaces of appliances like microwaves and refrigerators because of their easy manufacturing and thermal stability. You can even find styrene-butadiene copolymer in your toothbrush.

- Textiles and fashion industry: Copolymers are frequently used extensively in the production of fibers used in clothing and other fashion items. Their abilities to impart distinctive qualities, such as moisture-wicking, UV resistance, or even antibacterial capabilities have demonstrated their worth in the textile sector.

- Healthcare: Copolymers have brought a revolution in the fields of healthcare and medical devices. They play a major role in the development of medication delivery systems and in the creation of biocompatible, biodegradable products like stents and sutures.

4. EuroPlas - A world leading company for engineering materials

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers. With more than 15 years of producing and exporting engineering materials to thousands of businesses around the world, EuroPlas is proud to offer a wide range of products to help our customers produce high-quality plastic items.

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers. With more than 15 years of producing and exporting engineering materials to thousands of businesses around the world, EuroPlas is proud to offer a wide range of products to help our customers produce high-quality plastic items.

Our products include Filler masterbatch, Color masterbatch, Plastic additives, and Engineering plastic compound. Plus, we also pursuit sustainable development for businesses; thus, we have produced Bioplastic compound and Bio filler that are friendly to the environment and can satisfy your final products’ requirements.

If you have any questions about our materials, don’t hesitate to contact us. We are always happy to help.