When selecting ABS sheets for your project, it’s essential to make the right choice, whether you’re a professional working in manufacturing or a DIY enthusiast looking to create a sturdy prototype. Below, we'll guide you through the critical factors to consider when choosing ABS sheets to ensure your project is both successful and cost-effective.

1. Brief Overview Of ABS Plastic

ABS sheets are known for its wide applications

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer known for its wide range of applications, from automotive components to consumer products. ABS sheets offer remarkable durability, chemical stability, and impact resistance—qualities that have made them a staple in many industries. ABS plastic is tough, easy to mold, and affordable, making it a prime choice for creating various items from automotive parts to electronic enclosures.

1.1.Durability

ABS sheets are renowned for their long-lasting performance and robustness. Their ability to withstand physical impacts without cracking or deforming makes them ideal for heavy-duty applications, such as automotive parts, protective casings, and construction materials. They are designed to endure harsh conditions, making them a reliable choice for projects requiring strength and durability.

1.2. Chemical Stability

A standout feature of ABS sheets is their excellent resistance to a variety of chemicals, including acids and alkalis. This makes them a go-to material for environments exposed to potentially corrosive substances, such as laboratory equipment and chemical storage containers. This resistance ensures that ABS sheets remain intact even when exposed to harsh industrial chemicals, offering long-term performance.

1.3. Impact Resistance

One of the defining characteristics of ABS sheets is their high impact resistance. ABS can absorb significant amounts of shock without breaking, which is why it’s commonly used in the automotive industry for items such as bumpers and dashboard components. This property ensures that products made from ABS can withstand physical wear and tear over time, enhancing their durability.

2. Key Factors to Consider When Choosing ABS Sheets

When deciding on the right ABS sheets for your project, several important factors should be evaluated. Below are the key aspects to consider:

2.1. Size and Thickness

The dimensions and thickness of the ABS sheets you choose are directly tied to your project’s specific needs.

- Dimensions: The size of the sheets should be determined by the scale of your project. Large applications such as construction projects may require large ABS sheets, while smaller designs may only need compact pieces.

- Thickness: Different projects require different thicknesses. Thicker ABS sheets offer more strength and rigidity, while thinner sheets are more flexible. Ensure you choose the right thickness that meets your structural and performance requirements.

2.2. Color and Finish

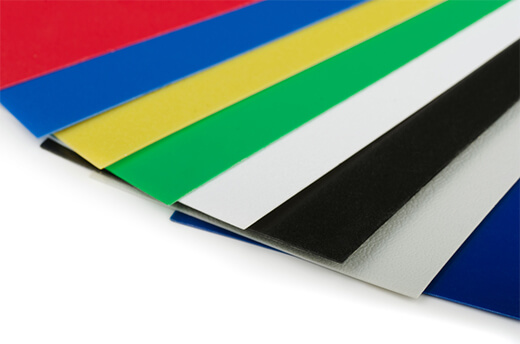

ABS sheets are in multiple colors

ABS sheets are available in a variety of colors and finishes, so it’s essential to consider both functionality and aesthetic appeal.

- Color Options: ABS sheets come in multiple colors. Depending on the nature of your project, you may need UV-resistant ABS sheets for outdoor applications to prevent fading. The color can also impact the product's overall look, so choose a color that enhances both functionality and appearance.

- Finish: Available finishes range from smooth to textured. A smooth finish might be ideal for aesthetic purposes or easy cleaning, while textured surfaces can provide grip or tactile quality for specific applications.

2.3. Surface Texture

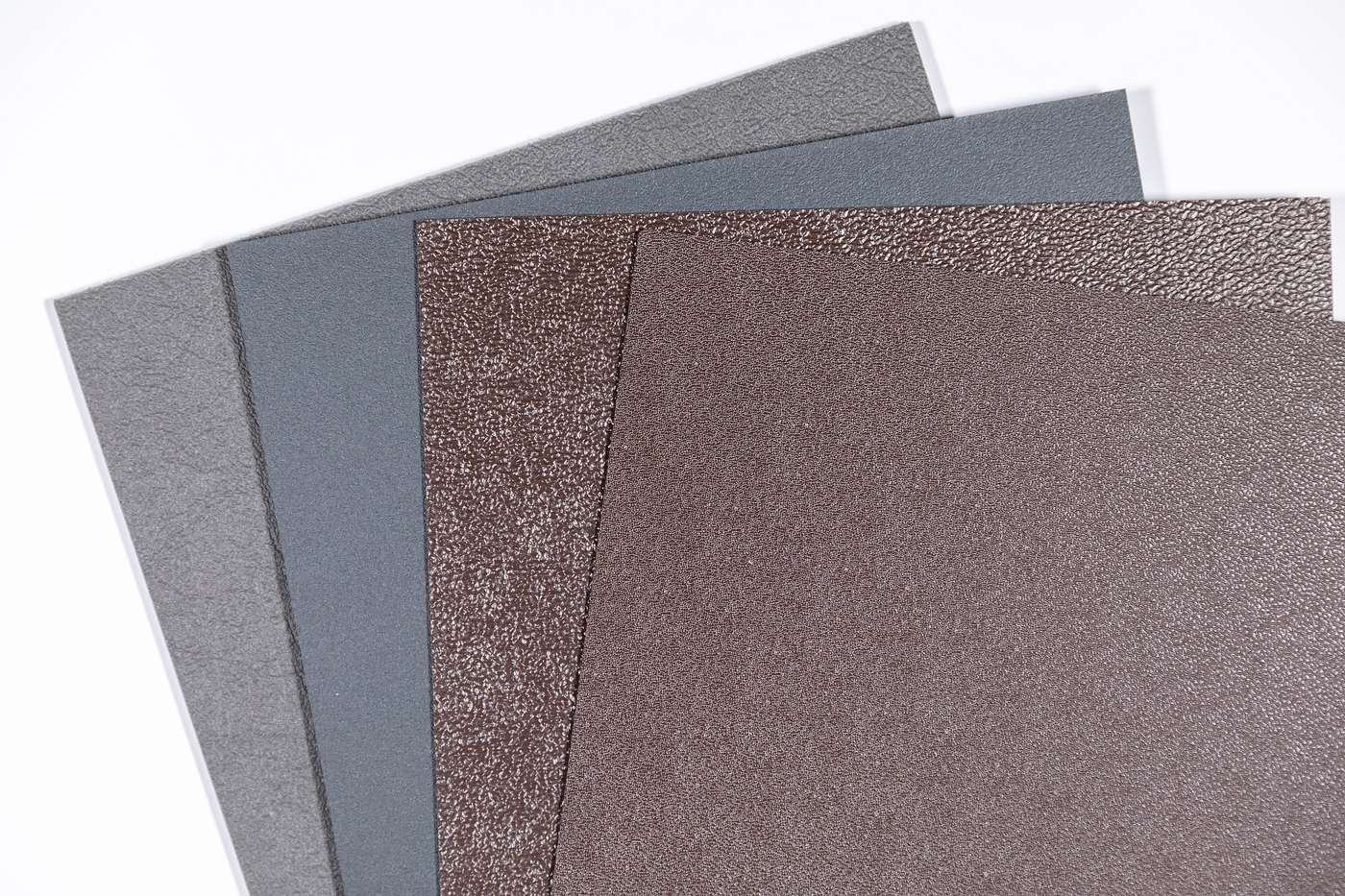

Surface texture can have a significant impact on both the functionality and visual appeal of ABS sheets.

- Functionality: Textured surfaces are great for grip, while smooth surfaces might be preferred in applications where ease of cleaning is important. Consider how the surface texture will interact with the environment in which it will be used.

- Aesthetic Appeal: The texture also plays a role in how the product looks. A textured finish might be used for rugged designs, while a glossy smooth finish can enhance a product’s sleek, modern appearance.

2.4. Special Properties

In certain situations, you might need ABS sheets with special properties to meet specific project requirements.

- Flame Resistance: If you are using ABS sheets in high-temperature environments, flame-retardant ABS may be necessary.

- UV Resistance: For outdoor projects, UV-resistant ABS ensures the sheets don’t degrade or fade due to sunlight exposure.

- Compliance: Depending on your industry, your ABS sheets may need to comply with certain regulations, such as FDA certification for food-related products or UL certification for electrical components.

2.5. Regulatory Compliance and Sustainability

ABS sheets should meet the industry requirements

It’s crucial to ensure the ABS sheets you select meet industry standards and environmental considerations.

- Certifications: Look for certifications like UL for electrical components or FDA compliance for food-related uses.

- Environmental Impact: As sustainability becomes increasingly important, consider ABS sheets that are recyclable or made from eco-friendly materials to reduce the environmental footprint of your project.

2.6. Quantity and Budget

Lastly, always consider the quantity you need and how much you’re willing to spend.

- Quantity: Larger projects will require bulk purchases, which may offer cost-saving opportunities. Always order slightly more than you need to account for mistakes or wastage during the production process.

- Budget: ABS sheets come in various price ranges depending on their quality, size, and special properties. Discuss your budget with your supplier to find the right balance between cost and performance.

3. Common Applications of ABS Sheets

ABS sheets are widely utilized across numerous industries due to their unique combination of strength, flexibility, and ease of fabrication. Their excellent mechanical and chemical properties make them suitable for both large-scale industrial applications and smaller consumer-oriented products. Here, we’ll explore some of the most common and significant uses of ABS sheets across different sectors:

3.1 Automotive Industry

ABS sheets used in the automotive sector

The automotive sector is one of the largest users of ABS sheets, and for good reason. ABS’s strength, lightweight nature, and impact resistance make it an ideal material for various interior and exterior automotive components. Its ability to withstand heavy wear and tear, combined with ease of molding, ensures it can be adapted to meet the complex design requirements of modern vehicles.

- Interior Components: ABS sheets are commonly used to manufacture dashboard panels, interior trims, door panels, and instrument clusters. These components require high durability and impact resistance to ensure long-lasting performance, even in the face of constant use. ABS also offers a smooth finish, which makes it aesthetically pleasing for car interiors.

- Exterior Components: In terms of exterior parts, ABS is frequently used to produce bumpers, mirror housings, and wheel covers. The material’s impact resistance is vital for automotive safety, particularly in areas prone to minor collisions. For example, ABS bumpers can absorb the force of impacts, reducing the likelihood of more severe damage to the vehicle.

- Customization: ABS is easy to mold and shape, which allows for the production of complex designs and intricate parts. This quality is particularly useful in the automotive industry, where manufacturers require precision-engineered components with tight tolerances.

3.2. Construction and Architecture

ABS sheets used in wall cladding

In the construction and architecture sectors, ABS sheets play an essential role in both structural and decorative applications. The ability of ABS to combine strength with visual appeal makes it an excellent material for various building and design projects.

- Wall Cladding: ABS sheets are often used in wall cladding, providing a durable and visually appealing surface that can withstand harsh environmental conditions. They offer protection from moisture, corrosion, and physical impact, which makes them ideal for both indoor and outdoor applications. Their flexibility in terms of design means that ABS sheets can be produced with different textures, finishes, and colors to suit specific aesthetic needs.

- Decorative Panels: Architects and interior designers frequently use ABS sheets for decorative panels. Whether smooth or textured, ABS panels can be customized to fit the desired look and feel of a space. Their ability to be easily fabricated into complex shapes allows for innovative designs in modern architecture, enhancing both aesthetics and functionality.

- Architectural Models: ABS sheets are also popular for creating architectural models. Their lightweight nature makes them easy to handle, while their strength and resistance to damage ensure the models can withstand repeated handling during presentations. Additionally, ABS is easy to paint and glue, making it a preferred material for precise and detailed model work.

3.3. Signage Industry

ABS sheets applied in signage industry

The signage industry relies on materials that can endure both outdoor and indoor conditions while retaining visual clarity and durability. ABS sheets meet these needs with their weather resistance, customization capabilities, and ability to hold vivid colors and graphics.

- Outdoor Signage: For outdoor applications, ABS sheets are valued for their ability to resist UV radiation, moisture, and extreme temperatures. These signs must maintain their integrity and appearance despite prolonged exposure to harsh environmental conditions. ABS sheets are ideal for promotional signs, directional signs, and advertising displays due to their durability and customizable surface finishes.

- Indoor Signage: For indoor use, ABS sheets offer excellent versatility. They are lightweight and easy to install, making them a popular choice for wayfinding signs, informational signs, and decorative signage in commercial spaces like shopping malls, airports, and office buildings. The material’s ability to be printed with high-quality graphics ensures that indoor signs are visually appealing and easy to read.

- Custom Graphics: ABS sheets can be easily printed on, allowing businesses to customize signage with logos, graphics, and text. This makes ABS a preferred material for companies looking to create branded signage that reflects their corporate identity while being durable enough to last for years.

3.4. Consumer Goods

ABS sheets applied in toys

In the consumer goods sector, ABS sheets are highly sought after due to their strength, ease of processing, and cost-effectiveness. They are used in the production of everyday products that require a combination of durability, lightweight properties, and aesthetic appeal.

- Toys: ABS sheets are commonly used in the manufacturing of durable toys. The material’s impact resistance ensures that toys can withstand rough handling without breaking, making it a safe and reliable choice for products designed for children. ABS is also easy to mold, allowing toy manufacturers to create a variety of complex and detailed shapes.

- Luggage and Cases: Many high-quality luggage brands use ABS sheets to produce lightweight, durable, and stylish suitcases. ABS’s strength and resistance to impact help protect personal belongings during travel, while its ability to be molded into sleek designs makes it aesthetically appealing. The material’s durability ensures that the luggage can endure the rigors of frequent travel without becoming damaged.

- Electronic Enclosures: ABS sheets are often used to create electronic housings for consumer devices such as computers, printers, and televisions. These enclosures must protect delicate electronic components from physical impacts, moisture, and temperature fluctuations. ABS is an excellent choice because it provides the necessary protection while being easy to fabricate into precise shapes that fit the required dimensions.

3.5. Industrial Equipment and Components

In industrial settings, ABS sheets are employed to create durable components that can withstand tough conditions, chemical exposure, and heavy usage. Due to its robustness, ABS is found in industrial machinery, storage containers, and laboratory equipment.

- Machinery Components: ABS sheets are used to produce various machine parts, particularly those that require durability and resistance to wear and tear. These components are critical in industrial environments where machinery is exposed to physical stress, making ABS an ideal material choice for ensuring longevity and performance.

- Chemical Storage: ABS’s chemical resistance makes it a suitable material for chemical storage containers and laboratory equipment. These applications often involve exposure to corrosive substances, and ABS’s stability in such environments helps ensure the safe and long-lasting storage of chemicals.

3.6. Medical Devices and Equipment

ABS sheets used in medical field

ABS sheets are increasingly being used in the medical field due to their ability to withstand cleaning agents and sterilization processes. Their smooth, non-porous surfaces make them easy to sanitize, an essential requirement in healthcare environments.

- Medical Enclosures: ABS is used to create housings for medical equipment, such as ventilators, defibrillators, and diagnostic devices. These enclosures protect sensitive electronic components while ensuring that the equipment remains safe to use in sterile environments.

- Prosthetics and Orthotics: ABS sheets are also used in the production of custom prosthetics and orthotic devices. The material’s lightweight nature, combined with its strength and ease of customization, allows for the creation of comfortable, durable medical devices that can be tailored to individual patient needs.

4. Conclusion

ABS sheets are a versatile and valuable material for many industries, offering durability, chemical resistance, and impact strength. However, choosing the right ABS sheets for your specific project requires careful consideration of factors like size, thickness, color, surface texture, special properties, and regulatory compliance. By taking these elements into account, you can ensure your project is successful and cost-effective, maximizing the benefits ABS sheets have to offer.

5. About EuroPlas’ ABS Products

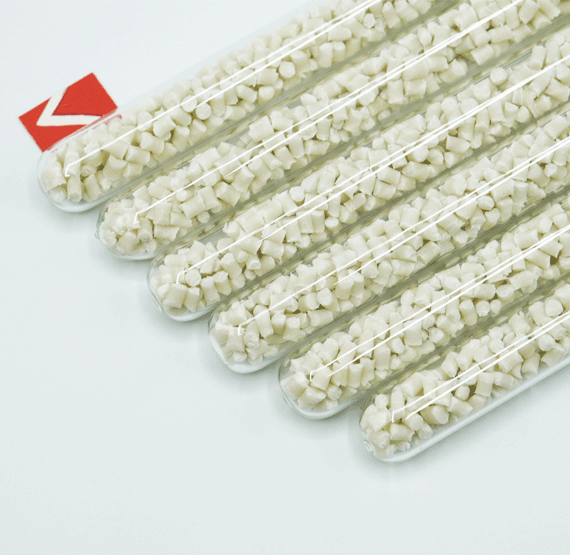

Compounds at EuroPlas can be used to make ABS sheets

EuroPlas stands at the forefront of masterbatch manufacturing in Vietnam, delivering premium ABS materials to meet the evolving needs of various industries. With a wealth of experience and cutting-edge technology, EuroPlas offers a broad spectrum of ABS products, each engineered to ensure superior performance and reliability. Our ABS plastic compounds and color masterbatches are created with the highest quality standards, making them ideal for applications in automotive, electronics, consumer goods, and more.

One of our most sought-after products is the ABS Glass Fiber Compound, which combines ABS resin with glass fibers to create a composite material with significantly enhanced strength, stiffness, and dimensional stability. The inclusion of glass fiber not only improves mechanical performance but also increases the heat deflection temperature, making it ideal for applications in the automotive industry (such as fuel tank caps and car interiors), printers, and earphone components. With a wide range of glass fiber content options, EuroPlas can customize this compound to suit specific product requirements, ensuring maximum efficiency and performance for our clients.

ABS Glass Fiber Compound at EuroPlas

Another specialized offering from EuroPlas is our ABS Flame Retardant Compound. This product is specifically designed to enhance fire safety in industries where flame resistance is critical, such as electronics, power devices, and household appliances. By incorporating halogen-free flame retardant additives, our ABS-FR compounds meet various fire resistance levels based on the UL94 standard (V0, V1, and V2). Despite its high flame retardancy, the material retains the desirable mechanical and physical properties of traditional ABS, making it both safe and reliable for a broad range of applications.

ABS Flame Retardant Compound at EuroPlas

In addition to our glass fiber and flame retardant compounds, EuroPlas also offers the ABS Antistatic Compound, which is engineered to prevent the buildup of static electricity. This material is crucial in the electronics and power sectors, where electrostatic discharge can be harmful to both products and users. By adding an antistatic additive to the ABS resin, this compound provides excellent electrical conductivity while maintaining the impact resistance and durability of ABS. It's an ideal solution for sensitive components such as electronic housings, mobile chargers, and power sockets.

ABS Antistatic Compound at EuroPlas

What sets EuroPlas apart is not just the quality of our materials but also our commitment to providing ongoing support throughout your product development journey. Our team of experts is always ready to offer technical advice, helping you select the ideal ABS material that aligns with both performance requirements and cost-efficiency goals. By partnering with EuroPlas, you gain access to deep expertise in ABS technologies and solutions tailored to the specific needs of your business.

Ready to learn more about how EuroPlas can support your project? Contact Us today to discuss how our ABS materials can help you achieve your goals.