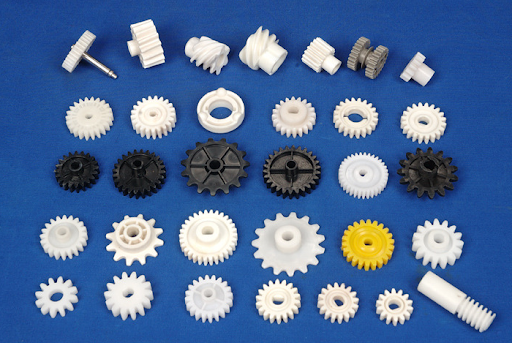

Plastic gears are an essential tool used to support machine operating systems, making the operating process many times easier and more convenient

The presence of plastic gears is increasingly popular in many diverse applications from technical and civil applications to children's toys. Notably, plastic gears are an essential tool used to support machine operating systems, making the operating process many times easier and more convenient. Finding the right material to produce plastic gears can help investors save a large amount of equipment production and operating costs. Let's update information about three types of high-performance plastic gears right below!

1. What are plastic gears?

Plastic gears are one of the popular support tools in many technical and life applications

Plastic gears are one of the popular support tools in many technical and life applications. The operating principle of plastic gears is based on the movement of saw-shaped parts to change the moving speed of the driven part. Plastic gears are often produced from technical plastics such as POM plastic, polyamide or Polycarbonate (PC)

Read more: What is plastic? Everything you need to know about plastic

2. Three Types of Plastic Suitable For Plastic Gears

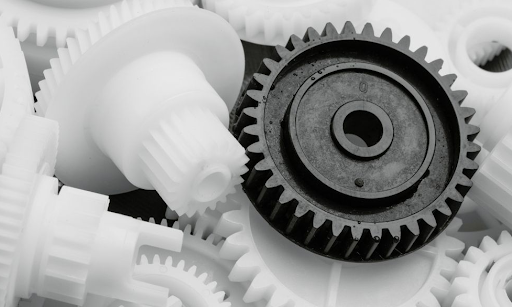

Plastic gears help the device operate more smoothly and save a large amount of energy consumption

One of the popular plastic types used to produce plastic gears is POM. Polyoxymethylene plastic is commonly known by the abbreviation POM or acetal plastic. They are produced by the polymerization of formaldehyde into long chains. POM is one of the plastic lines in the thermoplastic group that can be used to produce high-performance plastic gears.

POM is one of the materials that is evaluated for its performance. They are often commonly used in fields such as the production of component covers, processing of machinery parts, and the construction industry. Plastic gears manufactured from POM will bring many outstanding features to the application. POM plastic gears possess special mechanical properties, are durable, hard, anti-corrosion, high dimensional stability and easy to design in a variety of applications.

Nylon (Polyamide) is known as one of the leading plastic lines used to design plastic gears. On the current market, Nylon is divided into many groups based on their composition ratio. Each group will possess its own strengths in each different application.

Nylon (Polyamide) is considered one of the plastic materials that brings incredible performance to plastic gear systems. Plastic gears made from Nylon (Polyamide) demonstrate perfect durability. Nylon plastic gears can operate well in harsh environments thanks to their flexibility, hardness, impact resistance, abrasion resistance and extremely toughness. In addition, common application areas of Nylon (Polyamide) can be mentioned as automotive technology, aircraft technology, component casing, medical equipment, etc.

Polycarbonate (PC) is one of the bright candidates used to design a high-quality plastic gear. PC plastic is known as a material belonging to the thermoplastic group with carbonate functional groups. They are transparent and amorphous, making them extremely convenient in the process of shaping plastic gears.

Plastic gears are made from PC plastic with all the properties of a high quality product. PC plastic gears often have excellent durability, impact resistance, crack resistance and are extremely flexible. In particular, PC plastic is very flexible in making plastic gears. They can be melted and shaped into a variety of designs in shape and size. In addition, PC plastic gears are also environmentally friendly thanks to the fact that they can be recycled.

3. Conclusion

In conclusion, plastic gears are one of the devices that contribute significantly to speed regulation of various devices. Plastic gears help the device operate more smoothly and save a large amount of energy consumption. There are many types of materials that can be used to make plastic gears. Depending on the application requirements, we can choose a suitable material.

4. About EuroPlas

Our mission at EuroPlas is to provide optimal solutions for materials with a series of high-quality plastic lines. Our solutions meet the diverse needs of the world's industries, not only in terms of high standards and reliability but also in terms of environmental obligations. You can easily find engineering plastic compounds, fillers, colorants, plastic additives, biological fillers, etc. by contacting us now!