Unlike traditional plastic materials, such as PP, PE, ABS,…, additives or filler masterbatch, engineering plastic compound is still a relatively new material in the market. However, along with increasing complex requirements from the end-market, engineering plastics compound has become a new material solution chosen by many manufacturers, especially in the industrial sectors, which require high processing standards, such as electrical & electronics, construction, automotives, household appliances,…

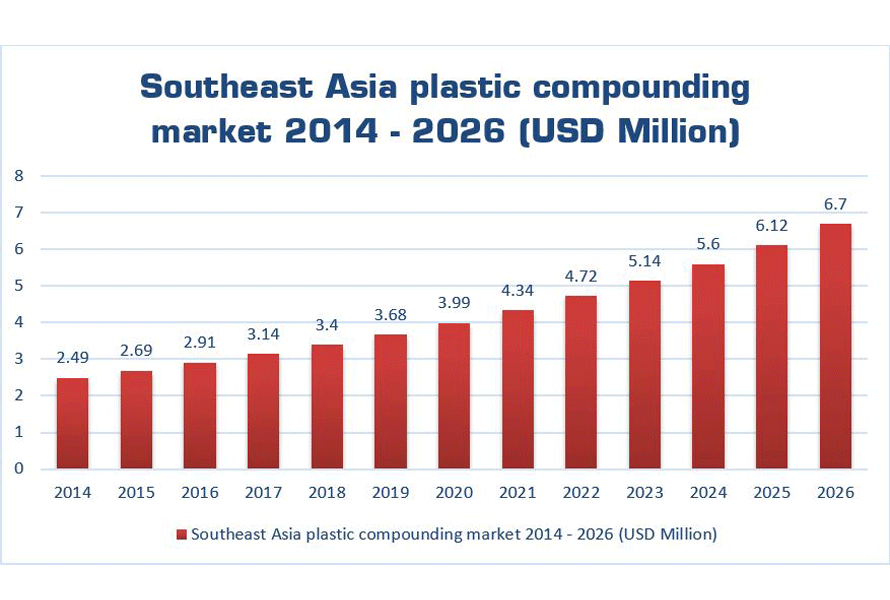

According to Grand View Research (2019), engineering plastic compound market is estimated to reach $6.7 million by 2026. So what makes this material attractive?

Plastic engineering compound market is estimated to reach USD 6.7 million by 2026

Plastic engineering compound market is estimated to reach USD 6.7 million by 2026

1. What is engineering plastic compound?

Engineering plastic compound is a combination of a traditional plastic base (PP, ABS, PC, ...) with appropriate reinforcements and additives in the form of masterbatch granules.

A special feature of this material is that there is no fixed formula or ingredient ratio. It all depends on the specific properties and technical requirements of the end-product to create a customized engineering plastic material. Therefore, compared to traditional plastic materials, engineering plastic compound has a much higher compatibility, making it easily meet all requirements of the end product.

Engineering plastic compound

2. Why should we use engineering plastic compound in household appliances?

Applying engineering plastic compound in household appliances brings the following benefits:

Tailor-made material solution for end-product

Before producing engineering plastic compound, manufacturers figure out characteristics and technical requirements of end-products, then select and mix all necessary materials in one single material. That’s why plastic engineering compound has all features of end-product, and is customized just for that end-product.

This advantage makes it specifically appropriate for products with complex processing and high mechanical precision requirements. At the same time, engineering plastic compound also eliminates all defects, such as mechanical deterioration or uneven dispersion on the plastic surface due to incompatible materials.

Simplify production, improve productivity

While traditional procedures require the mixation of several elements to create a single material, engineering plastic compound can be directly processed without blending with any other substances, as the compound itself is a comprehensive input material for end-products.

By simplifying the production process, plastic firms can save time, human resources, and increase productivity, thus creating a great competitive advantage for end-products, especially in the context of the fierce rivalry and fast-changing end market.

3. Common applications of engineering plastic compound in household appliances

With outstanding advantages, engineering plastic compound is widely used in several components of familiar items.

Rice cooker (lid, cover, rim, base,...)

The most common application of engineering plastic compound in rice cooker are facial plastic parts, such as the shell, rim, pot base,... PP compound is highly recommended thanks to its outstanding advantages, such as hardness, impact resistance, thermal and electrical insulation. Not only improving the mechanical properties of end-product, this material also helps manufacturers save time and labor by simplifying the processing of raw materials.

PP compound is commonly used in making plastic components of rice cookers

Super tepid (lid, handle, base,...)

In order to meet strict technical requirements regarding mechanical properties, aestheticity and durability of end-product, color engineering plastic compounds have been applied in the production of super tepid, such as lid, handle, base,… With the perfect combination of fossil resin, reinforcements and special additives, engineering compound brings good rigidity, bearing capacity, impact resistance for end-products, while adding special features, such as anti-slipping, heat insulation, aestheticity with various color choices.

Colored engineering plastic compound is used in making components of tepid, such as the lid, handle, base,...

Vacuum (handle,...)

Small as it may seem, vacuum handle has relatively complicated technical requirements in terms of technique and aesthetic appearance. To meet those requirements, compound ABS is the optimal choice. ABS resin, which is widely known for its good stiffness, bearing capacity, impact resistance and good electrical insulation, together with appropriate reinforcements and additives, has created a plastic engineering compound that meets the requirements of the end-products.

ABS engineering plastic compound is used in making vacuum's handles

Plastic chair

The application of PP engineering compound in plastic chairs has made a big difference compared to traditional PP resin. With the combination of appropriate reinforcements and additives, compound PP helps end products to have good rigidity, reduce shrinkage, enhance bearing capacity, impact resistance and wear resistance. Compound PP also offers a wide variety of color choices with good dispersion and color fastness.

Under the development of research activities, engineering plastic compound promises to be more and more widely applied in the household plastic industry in particular and plastic finished products in general.

4. EuroPlas compound engineering plastic

EuroPlas is a pioneer in the plastic materials market in general and the filler masterbatch market in particular. Engineering plastic compound is one of the latest innovations at EuroPlas. This is a perfect combination of fossil resin, reinforcements and special additives based on the characteristics of end-products. With outstanding advantages, plastic engineering compounds are widely applied in several industries, such as household appliances, electrical engineering, electronics,..., especially high-tech industries, such as automotives, electronics,…

Currently, EuroPlas supplies a wide range of engineering plastic compounds, such as PP compound, ABS compound, PC compound, PA compound,...

For detailed information and samples, please contact HERE