In an era where sustainability is at the forefront of our minds, finding alternatives to conventional plastics has become imperative. One such eco-friendly alternative is hemp plastic, a biodegradable and renewable material that can be crafted right in the comfort of your own home. By learning how to make hemp plastic at home, you can actively contribute to reducing plastic pollution and lowering your carbon footprint.

This DIY guide will walk you through the process step by step, from sourcing the essential ingredients to molding your very own hemp plastic creations. Not only is hemp plastic environmentally friendly, but it also offers numerous advantages over traditional plastics, including durability and versatility. Whether you're a passionate environmentalist or simply curious about sustainable living, this guide will empower you to take a proactive step towards a greener, cleaner future. So, let's roll up our sleeves and embark on a journey to create hemp plastic that's both fun and planet-friendly.

1. What Can You Make With Hemp Plastic At Home?

Hemp, a versatile and eco-friendly plant, is the foundation of the sustainable material known as hemp plastic. Derived from the fibers of the hemp plant (Cannabis sativa), hemp has been utilized for centuries for various purposes, including textiles, paper, and now, plastic.

Hemp plastic offers a greener alternative to conventional plastics, as it is biodegradable and renewable. But what can you create with this eco-conscious material?

- Everyday Items: Hemp plastic can be used to make a wide range of everyday items such as buttons, utensils, and even smartphone cases. These items are not only functional but also environmentally responsible.

- Containers and Packaging: Hemp plastic's durability makes it suitable for crafting containers, packaging materials, and storage solutions. It's a great choice for those looking to reduce single-use plastic waste.

- Art and Decor: Get creative with hemp plastic by using it to craft art pieces, decorative objects, or even jewelry. Its versatility allows you to explore your artistic side while making sustainable choices.

- Prototype and DIY Projects: Hemp plastic is an excellent material for prototyping and DIY projects. It can be shaped and molded to fit your specific needs, making it a valuable resource for inventors and tinkerers.

By learning how to make hemp plastic at home, you not only gain the ability to craft custom items but also contribute to reducing the environmental impact of traditional plastics. In the following sections of this guide, we will delve deeper into the process of making hemp plastic and explore creative applications that harness the potential of this sustainable material.

Read more: The pros and cons of hemp bioplastic

2. How to Make Hemp Plastic at Home

Making hemp plastic at home is an exciting and sustainable DIY project that allows you to reduce your reliance on traditional plastics and contribute to a greener environment. In this section, we will walk you through the step-by-step process of creating hemp plastic right in your own kitchen.

2.1. Materials You'll Need:

- Hemp Fibers: Begin with raw hemp fibers. These can be obtained from hemp plants, which are a sustainable and rapidly renewable resource. Ensure the fibers are clean and free of impurities.

- Hemp Oil: Hemp oil, also known as hemp seed oil, acts as a binding agent for your hemp plastic mixture.

- Plasticizer: You'll need a plasticizer to bind the hemp fibers together and give your plastic its malleable properties. One common option is polylactic acid (PLA), a bioplastic derived from corn starch.

- Heat Source: You'll require a heat source for melting the plasticizer. A stovetop or a hot plate works well for this purpose.

- Mixing Tools: You'll need mixing bowls, a spoon, and measuring cups for accurate measurements.

- Mold: To shape your hemp plastic into various forms, you'll need molds. These can be simple shapes or more complex designs depending on your project.

2.2. Step-by-Step Guide:

- Prepare Your Hemp Fiber: Begin by cutting or shredding the hemp fiber into small pieces. The size and texture of the fibers will affect the final appearance and texture of your hemp plastic.

- Mix the Ingredients: In a mixing bowl, combine the shredded hemp fiber with hemp oil. You can add a natural plasticizer like glycerin if you desire greater flexibility in your finished product. The exact ratios will depend on your project and the desired properties of your hemp plastic. Start with a small batch to experiment with proportions.

- Thoroughly Mix: Use a spoon or your hands to thoroughly mix the ingredients until you achieve a consistent, dough-like texture.

- Mold Your Hemp Plastic: Press the mixture into your chosen mold, making sure it's evenly distributed. You can use your hands or a tool to shape the hemp plastic as needed.

- Let it Set: Allow your hemp plastic to dry and set. The drying time may vary depending on the size and thickness of your project. Generally, it may take a day or more for the hemp plastic to fully harden.

- Remove from the Mold: Once your hemp plastic is completely dry and solid, carefully remove it from the mold.

By following these steps, you can create a variety of eco-friendly hemp plastic items, from simple utensils to intricate decorative pieces. Making hemp plastic at home not only reduces your environmental impact but also provides a hands-on way to explore sustainable alternatives to traditional plastics.

EuroPlas, based in Vietnam, has established itself as a frontrunner in the masterbatch manufacturing industry with a remarkable 15-year legacy. Our global presence spans across 85 countries, underpinned by our unwavering commitment to delivering innovative and sustainable plastic solutions.

Tailored Solutions for Your Industry: At EuroPlas, we harness cutting-edge technology and unique natural resources to craft customized products for a wide array of industries. Whether you're seeking cost-effective options or environmentally conscious alternatives, EuroPlas is your steadfast partner in navigating the ever-evolving world of plastics.

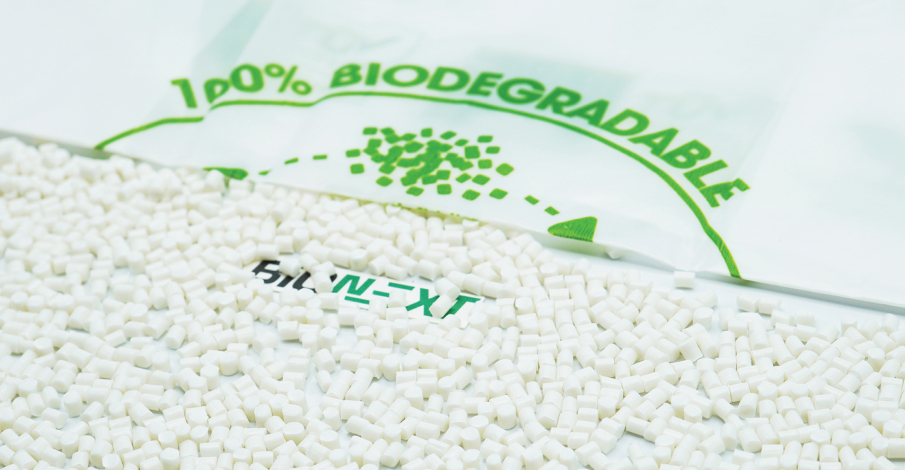

In a resolute stride towards a more eco-conscious future, EuroPlas proudly presents our bioplastic compound. Crafted from natural starch and biodegradable additives, this pioneering solution enables plastic items to biodegrade within a year while maintaining peak performance. Applications range from food packaging to agricultural films, underscoring our resolute dedication to environmental sustainability.

Our dedication to sustainability knows no bounds, as evidenced by our bio filler—an eco-friendly alternative that renders plastic items biodegradable within a year. Comprising natural starch and biodegradable additives, this innovative product is perfectly suited for food packaging, disposable tableware, and agricultural films, offering a greener tomorrow without sacrificing functionality.

At EuroPlas, our diverse product range mirrors our unyielding commitment to shaping a more sustainable and innovative future. We center our efforts on quality, performance, and environmental responsibility, consistently making a profound impact on the global plastic industry.

We extend our heartfelt gratitude for considering EuroPlas as your partner for cutting-edge plastic solutions. Our dedicated team stands ready to offer expert guidance and support tailored to your unique requirements. Whether you have inquiries about our products, seek customized solutions, or wish to collaborate on sustainable initiatives, we are here to serve you—reach out to us today!