Because the problems of environmental pollution caused by plastic waste are becoming increasingly alarming, reusing plastic waste has become an extremely necessary thing. The article below will guide you on how to 3D print to reuse plastic bottles, minimizing negative impacts on the environment.

1. What is 3D printing?

3D printing is the process of transforming a digital model into a physical, solid, three-dimensional object by depositing successive, thin layers of material. Its rapid popularity can be attributed to its accessibility, enabled by affordable prices (starting as low as $300 for basic 3D printers) and the compact size of the printers in comparison to traditional manufacturing equipment.

Initially, a virtual blueprint of the object is created using computer-aided design (CAD) software, capable of generating precise technical illustrations. Alternatively, a 3D scanner can be used to replicate an existing object by capturing images of it from different angles.

The next step involves preparing the virtual model for printing. This preparation includes a process called slicing, where the model is divided into numerous horizontal layers using specialized software. These slices are meticulously prepared for the 3D printing process.

Once the model is sliced, the resulting layers are transferred to the 3D printer. This transfer is facilitated through a USB cable or Wi-Fi connection, allowing the sliced model to be transmitted from the computer to the 3D printer. The printer then reads each slice of the model and meticulously constructs the physical object layer by layer.

2. Preparing plastic bottles for 3D printing

Plastic bottles should be cleaned for 3D printing

You can follow these steps to prepare 3D-printed plastic bottles:

- Collection and Sorting: Gather plastic bottles made from suitable materials for 3D printing, typically PET (Polyethylene Terephthalate) plastic. Ensure the bottles are clean and free from labels, caps, and any contaminants.

- Cleaning: Thoroughly clean the bottles to remove any residue, labels, and adhesives. Use warm water and mild detergent to clean the bottles effectively. Proper cleaning is essential to ensure the quality of the final 3D-printed filament.

- Drying: After cleaning, let the bottles dry completely. Moisture in the plastic can affect the quality of the filament and the 3D printing process.

- Cutting: Cut the plastic bottles into small pieces or shred them into tiny flakes. Smaller pieces are easier to handle and feed into the filament extruder. You can use a paper shredder to do this step, which will save you time and effort.

- Extrusion: Use a filament extruder machine to melt and extrude the plastic pieces into a filament form.

You should follow this process and monitor the filament diameter and consistency during the extrusion process. Variations in diameter and size can affect the printing quality. After finishing, spool the extruded filament onto a 3D printing filament spool. Ensure it's neatly wound to prevent tangles during the printing process. Store the spooled filament in a dry and airtight container to prevent moisture absorption, which can lead to printing issues.

Remember, the process might vary based on your specific 3D printer and extrusion setup. It's crucial to follow the guidelines provided by the equipment manufacturer and any filament extrusion guides specific to your setup. Proper preparation and attention to detail are key to successful 3D printing with recycled plastic bottles.

Read more: What is plastic? Everything you need to know about plastic

3. Use plastic bottles for 3D printing - how does it work?

How to make objects by using plastic bottles for 3D printing

First, a digital design of the object is created using computer-aided design (CAD) software or a 3D scanner. To prepare the design for printing, it is sliced into numerous thin layers using specialized software. Imagine the object being cut like a loaf of bread into hundreds or even thousands of horizontal slices.

Once these layers are ready, they are sent to the 3D printer. Using a USB cable or Wi-Fi connection, the sliced model is transferred from the computer to the 3D printer. The printer then reads each slice and starts printing.

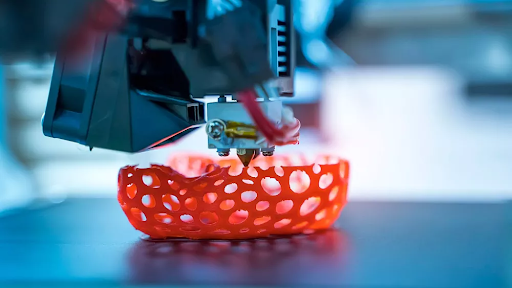

The 3D printer uses a process called material extrusion. In this method, a nozzle releases a semi-liquid material, such as melted plastic, metal, or cement. The nozzle can move both horizontally and vertically, precisely placing the material layer by layer according to the digital blueprint.

This layer-by-layer printing continues until the entire object, as designed in the digital model, is replicated with the extruded material. It's akin to building the object slice by slice, ultimately creating a three-dimensional version of the virtual design.

The 3D printer is printing the designed object

4. What kinds of objects can be created using plastic bottles for 3D printing?

Using plastic bottles for 3D printing opens up a world of creative possibilities. Here are some items that can be made using plastic bottles as filament:

4.1. Household items

With 3D printing, plastic bottles can be transformed into various household essentials. Imagine having personalized containers and organizers tailored to your specific needs, providing a clutter-free space. For plant enthusiasts, eco-conscious planters made from recycled plastic bottles offer a sustainable and stylish way to display greenery indoors or in the garden.

Additionally, decorative vases and flower holders can adorn your home, adding a touch of creativity to your decor. Practical items like pen holders, cable organizers, soap dishes, reusable drinking cups, and key holders can all be crafted using 3D printing, not only reducing plastic waste but also promoting an eco-friendly lifestyle.

Flower vases are created by 3D printing

4.2. Artwork

Artistic expression knows no bounds with 3D-printed sculptures and figurines made from recycled plastic bottles. Artists can create intricate and unique pieces, showcasing their creativity and contributing to environmental conservation simultaneously.

For example, lampshades, an essential part of home lighting, can be designed with intricate patterns, casting beautiful shadows when illuminated. Or wall art, ranging from decorative panels to ornate frames, adds aesthetic value to any space. Moreover, customized clocks with various shapes and designs can be a focal point in any room, reflecting your individual style.

4.3. Learning support tools

Repurposing plastic bottles for 3D printing learning support tools is an innovative and sustainable approach that combines technology, environmental consciousness, and education. Teachers can customize learning support tools to cater to the diverse needs of students. For example, using plastic bottles and 3D printers to create geometric shapes, number lines, or fraction models for interactive math lessons. Or printing 3D models of cells, organs, or scientific concepts to enhance biology and chemistry lessons.

4.4. Fashion and accessories

Earrings, bracelets, and necklaces can be crafted by 3D printing plastic bottles with beautiful, intricate designs promoting eco-conscious fashion choices. Likewise, hair accessories such as clips, combs, and pins are both functional and stylish. Fashion accessories such as buckles, buttons, and ornaments serve creative fashion designers, providing them with environmentally friendly materials.

4.5. Technology accessories

Phone case 3D printing designs

3D printing technology brings diversity to the creation of everyday technology accessories. Custom phone cases with unique designs not only protect your phone but also express your personality. Tablet stands, intricately designed and adapted to specific tablet models, offer convenient and stylish solutions for device use. Camera enthusiasts will surely love lens accessories and tripods that are 3D printed from plastic bottles.

4.6. Environmental protection initiatives

3D printing contributes significantly to environmental initiatives. Specialized recycling bins, 3D printed from plastic bottles, serve as visible symbols of recycling awareness, encouraging proper disposal practices. Lightweight and durable trash pickers that volunteers can use during beach cleanups can also be 3D printed from used plastic bottles.

5. Conclusion

In conclusion, using recycled plastic bottles for 3D printing is not just a creative endeavor but also a vital step towards environmental conservation. Transforming discarded plastic into useful and visually appealing products serves a dual purpose: it reduces plastic waste while encouraging the message of reusing plastic waste.

Read more: What type of plastic is used in 3D printers?