Plastic additives play an important role in improving processing, enhancing current properties, or imparting new properties of the finished products. The demand for plastic additives has been steadily rising in recent years, especially in end-to-end industries such as aviation, automotive, medical, electronics, and construction. However, various factors influence plastic additives, including raw material costs, supply and demand dynamics, regulatory environments, and consumer trends.

This article aims to provide insightful predictions about the price trends of plastic additives in 2025.

1. Overview of Plastic Additives

Plastic additives refer to substances added to polymers during plastic production to enhance polymer properties and performance. Some of the most common additives utilized in plastic manufacturing include plasticizers, stabilizers, pigments, fillers, and flame retardants.

- Stabilizers: Stabilizers help protect polymers from degradation caused by exposure to oxygen, heat, or light. These additives include UV stabilizers, antioxidants, and heat stabilizers, which excel in maintaining the appearance and properties of plastic over time.

- Plasticizers: Plasticizers work by making polymers softer and more pliable, reducing the glass transition temperature and thereby enhancing the processability and flexibility of the polymer. Plasticizers find wide application in PVC manufacturing, coatings, adhesives, and sealants.

- Fillers: To enhance the durability, strength, and stiffness of plastic products, fillers are among the top additive choices, especially in thermoplastic manufacturing. Common fillers include glass fibers, calcium carbonate, carbon black, and talc.

- Pigments: These plastic additives absorb UV radiation and prevent degradation caused by sunlight exposure, thereby enhancing the weatherability of the polymer. Titanium dioxide, carbon black, and iron oxide are among the most popular pigments. Manufacturers can apply these pigments in the production of consumer goods such as housewares, packaging, and toys.

- Flame retardants: The purpose of using flame retardants in plastic manufacturing is to reduce the flammability of the polymer and prevent the spread of fire. They achieve this by reducing the release of flammable gases through the release of gases and water, or by forming a char layer that acts as a barrier against the spread of fire. Thanks to these significant advantages, flame retardants are widely used in industries that require high fire safety standards, such as transportation and construction.

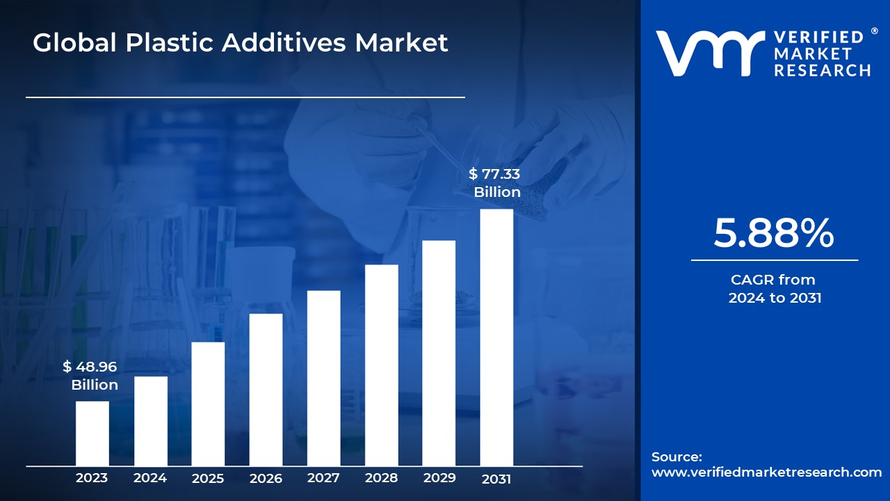

According to Fortune Business Insight, the global market for plastic additives was valued at USD 56.69 billion in 2023 and is projected to increase to USD 60.35 billion in 2024, reaching USD 93.85 billion by 2028. Businesses worldwide are increasingly focusing not only on the functionality and biodegradability of plastic products but also on their safety for consumers. This trend marks a shift for global plastic additives manufacturers towards developing products that are sustainable and environmentally friendly.

2. Historical Price Trends

In the last few decades, the dramatic increase in plastic waste has become alarming, laying a burden on global authorities to find efficient solutions. The rising concerns regarding plastic pollution have spurred plastic manufacturers' demand for biodegradable materials.

Since 2019, plastic manufacturers have increasingly utilized biodegradable polymers instead of traditional ones. Similarly, in the realm of plastic additives, companies are seeking additives that can enhance the biodegradability of plastic products.

Moreover, following the significant impact of the global COVID-19 pandemic, consumers have become more inclined to use products manufactured under strict health and safety regulations. In the field of plastic additives, many large companies worldwide are endorsing the use of sanitized additives with antiviral properties for polymers. These additives are expected to see wider application in transportation, food and beverages, healthcare, and other essential sectors.

The COVID-19 pandemic also disrupted the global market significantly, including the market for plastic additives. Prices of plastic additives fluctuated during that time due to instability in commodity manufacturing and supply, as well as the availability of raw materials.

Overall, there are 3 main factors affecting the plastic additives price:

- Raw material costs: The cost of raw materials partly determines the price of finished products. During the COVID-19 pandemic, the supply of raw materials used to make plastic additives was disrupted due to lockdowns, particularly in China, a key supplier significantly affected by the global pandemic. Understandably, prices increased due to the scarcity of materials.

- Supply and demand dynamics: The demand for plastic additives has remained robust over the years. When supply fails to keep pace with demand, prices inevitably rise.

- Regulatory changes: Many strict regulations have been implemented, which have dramatically changed the global market for plastic additives. For instance, the European Commission has released numerous regulations to limit the use of flame retardants and other additives that negatively affect human health and the environment.

3. Key Factors Influencing Future Prices

Below are the key factors influencing future prices of plastic additives:

- Raw Material Costs: The cost of raw materials for producing plastic additives can be directly influenced by crude oil prices because some additives are derived from petrochemicals.

- Supply Chain Dynamics: There are many factors affecting the availability of raw materials, such as geopolitical issues, natural disasters, global pandemics, and production shutdowns. The interruption of raw material supply can cause cost fluctuations, resulting in price changes.

- Market Demand: The potential increase in the price of plastic additives can be caused by market demand. Specifically, economic growth can drive higher demand for plastic additives, especially in key markets such as automotive, construction, and packaging. The shift in consumer preferences can also drive changes in product demand, resulting in price fluctuations.

- Technological Advancements: Thanks to technological advancements, the production process can be simplified to reduce production costs. However, manufacturers also need to consider that new technology must comply with stricter regulations, which can increase costs.

- Regulatory and Environmental Factors: Since the world is more aware of environmental protection and consumers prioritize health and safety, many strict regulations have been established among countries, leading to increased costs for compliance and reformulation.

4. Expert Predictions for 2025

According to Lucintel Insight, the global plastic additive market is predicted to be valued at $48.5 billion by 2025. Also, there are some changes that are expected to impact the global plastic additive market.

- Rising demand for bioplasticizers: Stricter government regulations and increased consumer health concerns have led to rising demand for renewable and biodegradable resources. This demand has been a driving force for the invention of bioplasticizers, which are made from natural raw materials. Bioplasticizers not only help reduce carbon footprints but are also safe for consumer health.

- Growing use of non-halogenated flame retardants: There are more safety standards established in the plastic manufacturing industry. This industry has witnessed a switch from halogenated flame retardants to non-halogenated flame retardants. Some of these additives are becoming more popular due to their eco-friendliness and cost savings, such as ATH and organo-phosphorus.

- Increasing utilization of organic plastic pigments: Organic pigments play a significant role as colorants in plastics. In response to growing environmental regulations, plastic manufacturers have been shifting towards using organic pigments for sustainability.

5. Strategies for Manufacturers and Buyers

In fact, manufacturers who can catch up with market trends will gain competitive advantages and the potential to become key players. Here are some strategies based on the predicted trends in the plastic additives market that manufacturers can refer to:

- Focus on developing and utilizing bio-plasticizers, which can help reduce the carbon footprint, ensuring sustainability and enhancing corporate image.

- Increase the use of organic plastic and antioxidant polymer additives, which are expected to be trending additives in the future.

- Invest in non-flame retardants due to their eco-friendliness.

- Put effort into continuous R&D activities to invent low-cost and sustainable plastic additives.

6. Conclusion

Plastic additives play a vital role in the plastic manufacturing industry. Selecting appropriate plastic additives not only helps enhance the properties of finished products but also contributes to the success of plastic manufacturing projects. By understanding the price trends and demands of the additives market, manufacturers can develop products that satisfy customer needs and save costs.

7. About EuroPlas

Here at EuroPlas, we offer customers a vast range of plastic additives, including deodorizing/odor-removing additives, desiccant additives, flame retardant additives, anti-fog additives, anti-aging additives, processing aids, anti-static additives, anti-UV additives, and additives to increase clarity and brightness.

We are also promoting the use of bioplastics and biodegradable materials in the plastic manufacturing process. EuroPlas is committed to supporting global plastic manufacturers shoulder-to-shoulder to achieve sustainability. Contact us for more information!