Currently, Epoxy resins are very popular in many industries. Based on physical characteristics as well as molecular structure properties, Epoxy Resin is capable of competing with common plastic materials such as polypropylene (PP), Polycarbonate (PC), Polyvinyl chloride (PVC), etc. So is Epoxy resin toxic? In this article EuroPlas will provide complete knowledge about Epoxy resin. There will be a lot of interesting information that you may not know about Epoxy resin. Please refer to it now!

Epoxy resin in glue form

1. Overview and definition of Epoxy resin

First of all, let's refer to the definition of Epoxy resins to have a general perspective on them!

The origin of Epoxy resin material comes from composite resin, which is an organic active ingredient. In particular, Epoxy resins are more resistant to environmental impacts than conventional plastics because of their special physical and mechanical properties.

Besides, the chemical structure of Epoxy resin does not contain molecules of the Ester group, which form deposits, creating plasticity and stable water resistance over time.

Epoxy resin shapes are widely used in industries

Epoxy resin is also known as one of the families of monomeric or polymeric materials, which have the ability to react to form thermophilic polymer molecules. This qualifies Epoxy resin to resist strong chemicals or high solvents, thereby forming adhesion. Thanks to its chemical structure, the flexibility of Epoxy resin is much superior to other materials in the same segment.

2. Special features in the structure and chemical composition of Epoxy resin

Epoxy resin is one of the plastic materials that possesses a quite complex molecular structure, but is also very attractive to scientists.

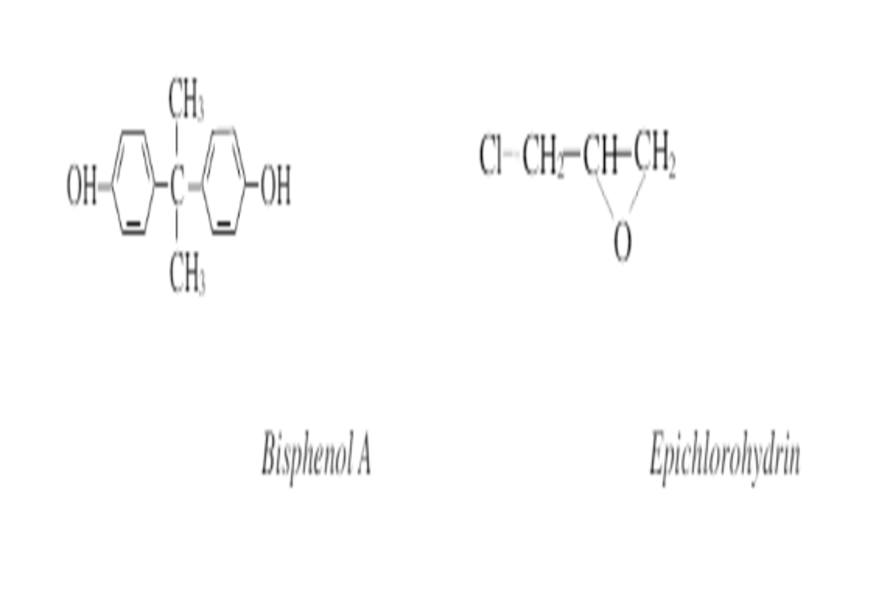

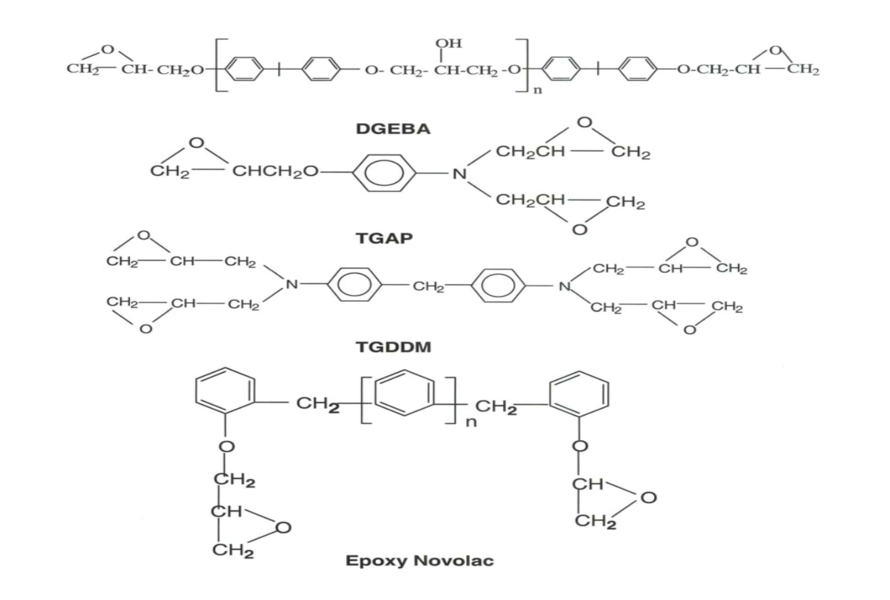

The chemical composition includes Epoxide groups formed from cross-links in the molecule. Besides, raw materials such as epichlorohydrin and bisphenol-A are also indispensable ingredients to create standard Epoxy resin.

Production of Epoxy resin

The introduction of curing agents and catalysts initiates the cross-linking process, resulting in the conversion of liquid resins into solid materials with exceptional mechanical strength and thermal stability.

Epoxy resin was born in the 1950s in Australia and is widely used in heavy industries. In particular, Epoxy resin is also understood as any polymer system where epoxide or oxirane rings will participate in the Binder synthesis process together. Therefore, Epoxy resin is classified as a thermosetting resin.

3. Is Epoxy resin toxic and how to use Epoxy resin properly

Scientists have proven that the composition and chemical structure of Epoxy resin does not affect the health of consumers. However, to achieve maximum effectiveness during use, we should also note some important information about how to preserve Epoxy resin. As follows:

- Epoxy resin will be better if stored at low temperatures and limited to moldy areas or exposed to direct sunlight.

- When you come into contact with Epoxy resin, you also need to use protective gloves to avoid allergies. Allergic symptoms of Epoxy resin are only minor and do not have a major impact. However, people with sensitive skin will experience itching and discomfort for a period of time.

- If you are allergic to Epoxy resin on your skin, you can use vinegar. In case you want to disinfect items that have come into contact with or are made from Epoxy, Acetone solution is the right choice.

- Besides, Epoxy resin when not in solid state and catalysts can affect the environment. When putting excess Epoxy in the trash, we must wrap it carefully with a plastic bag.

4. Classification of Epoxy resin

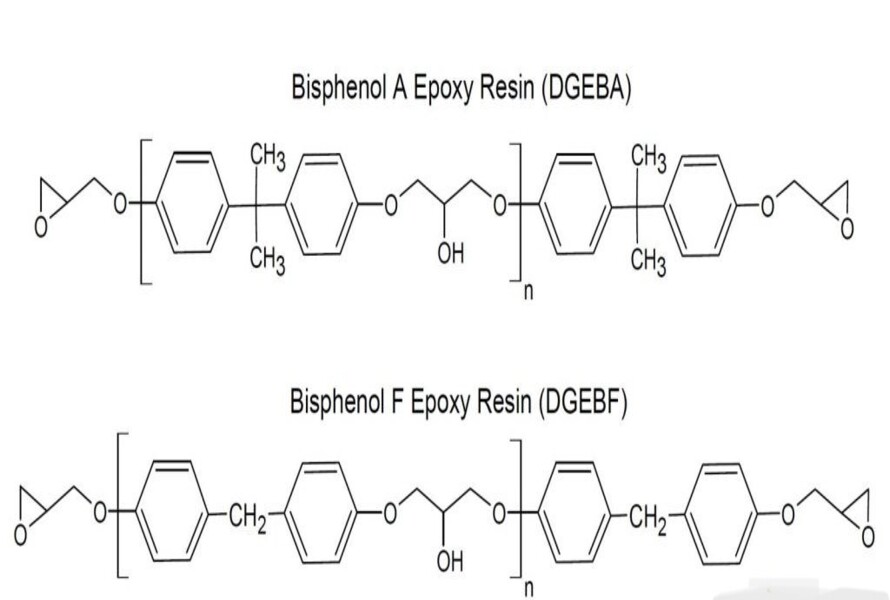

Currently, the market has 3 most popular types of Epoxy resin: Bisphenol - A based Epoxy Resin, Bisphenol - F based Epoxy Resin, Novolac based Epoxy Resin. Each type will possess unique characteristics and properties.

4.1 Bisphenol-A based epoxy resin

This is an Epoxy resin combined from Bisphenol A and Epichlorohydrin. This type of Epoxy resin is resistant to impacts from environmental temperatures and chemicals as well as has high hardness. The main reason is because it possesses the compound Bisphenol - A in its composition structure.

In particular, Bisphenol - A-based Epoxy Resin can also resist strong chemicals because the structure only contains carbon bonds and Ether groups instead of ester groups.

Bisphenol-A based epoxy resin

Furthermore, this type of Epoxy resin is not too difficult to combine and interact with other plastic materials because they possess hydroxyl groups and epoxy groups at the beginning of the chain.

4.2 Bisphenol-F based epoxy resin

Bisphenol - F based Epoxy Resin has a similar structure to Bisphenol - A. The difference between them is that Bisphenol - F based Epoxy Resin only has a methylene group connecting two benzene rings instead of the isopropylidene group in Bisphenol - A.

This causes Epoxy Bisphenol - F resin to have lower viscosity as well as reduce the vitrification process. For example, the standard molecular viscosity of Epoxy Bisphenol - A will be above 10,000 to about 16000 cps. Meanwhile, this figure for Epoxy Bisphenol - F resin is only from over 3000 to 8000 cps.

Bisphenol-F based epoxy resin

Besides, the molecular weight of Bisphenol - F based Epoxy is also 4 - 5 times lower than that of Bisphenol - A. However, the strength of Bisphenol - F Epoxy resin comes from the methylene connection of the two groups. phenolic instead of isopropyl group in Bisphenol A-based epoxy resin.

Therefore, they will have increased heat resistance, better chemical or solvent resistance and stable vitrification temperature.

4.3 Novolac-based epoxy resin.

The tight structure is the most outstanding strength of Novolac-based Epoxy resin. In particular, this is further evidenced when Novolac-based Epoxy resin will still maintain sustainable chemical resistance even when directly exposed to high temperatures of about 260 degrees Celsius and pressure levels of up to 69 Mpa.

The viscosity of Novolac-based Epoxy resin is the highest among the three types, estimated parameters range from 30,000 to about 500,000 cps. Epoxy resin is often used in powder paint production. In particular, the high resistance to solvents and chemicals is maximized when they are combined with aliphatic amines.

Novolac-based epoxy resin

5. General characteristics of Epoxy resin

Epoxy resin has also proven that its characteristics and properties are competitive compared to other types of resin on the market.

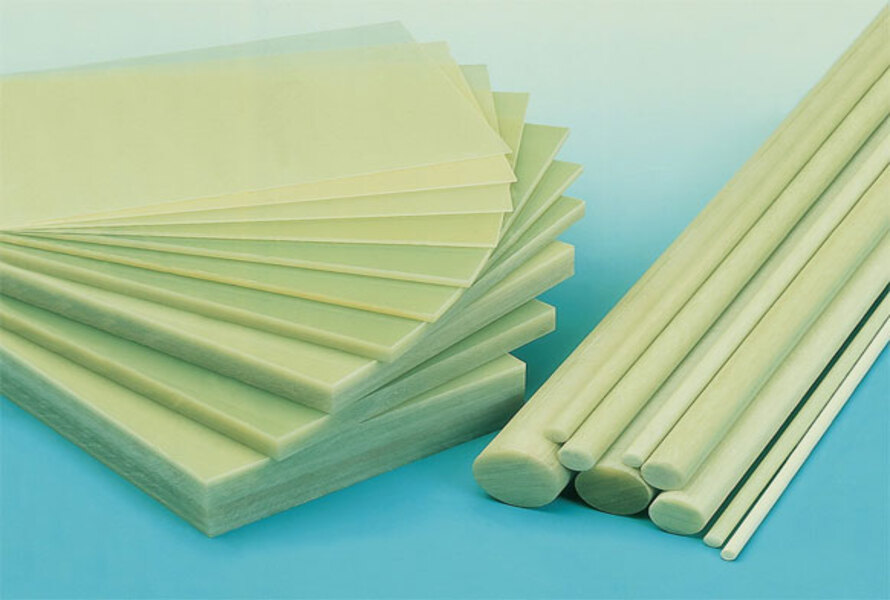

- Mechanical properties and temperature: Epoxy resin has quite high compression and tensile strength. It is well applied in high-strength products. The temperature resistance of Epoxy resin is also very admirable when the heat resistance level can reach over 260 degrees Celsius for a long time, which helps them to be used in the energy or electronics industry. In addition, Epoxy resin allows manufacturers to easily create shapes because of its flexibility in chemical structure, for example Epoxy resin can be made into powder paint or adhesive compounds.

Epoxy resin is classified as a thermosetting resin

- Thanks to the vacuum structure, manufacturers do not have difficulty combining Epoxy with other plastics or plastic additives to increase core characteristics.

- Low shrinkage during the curing process is also an advantage of Epoxy resin. Therefore, Epoxy resin adheres well to a variety of material surfaces such as wood, concrete, glass or metal. They are commonly used in the 3D decoration industry.

Epoxy resin blanks have good characteristics in terms of physical and mechanical properties

- Because Ester groups do not exist in the chemical structure of Epoxy resin, they have good heat resistance, resistance to chemicals or solvents, and good water resistance. Besides, Epoxy resin is also used as an electrical resistor and is quite popular in mechanical engineering.

However, Epoxy resin also has certain weaknesses, but they are not too many and do not too much affect the quality of the final product. Weaknesses are as follows:

- If Epoxy resin is not prepared properly, it will be difficult to reach standard hardness levels and productivity will not be high.

Nhựa Epoxy được sản xuất thành các miếng nhựa cứng phục vụ cho các ngành công nghiệp nặng

- Epoxy resin when made into paint products can cause odors or skin allergies.

- Epoxy resin in the form of paint or liquid products is easily affected by UV rays

6. Application of Epoxy resin

- Interior decorations: Epoxy resin is combined with coloring agents and used as a coating on the surface of interior products such as tables and cabinets. Epoxy glue will help the product increase gloss, limit internal effects, improve quality as well as increase product value.

- Jewelry industry: Epoxy is produced in liquid form into glue. They are then combined with accessories or colors according to customer preferences and condensed into a solid form

Epoxy resin application in the production of decorative jewelry items

- House construction: Epoxy resin is used as a coating on the surface of the house. It not only decorates and increases luxury, but also protects the floor from deterioration or mold.

- Electronic equipment: because of its insulating properties, Epoxy can also be used in the electronics industry. For example: circuit boards, thermal paste or glass panels.

- Production of glues: This is the most common application of Epoxy plastic materials. Glue made from Epoxy resin adapts to almost any material surface such as wood, aluminum, glass or metal.

Epoxy resin is used as a surface coating

- Daily items: Epoxy resin has antibacterial properties, they are also used in the production of plastic bowls, bowls, and chopsticks used in daily life.

- Medical industry: In particular, Epoxy resin is combined with plastic additives to increase resistance to acids, chemicals or strong solvents. This combined with its antibacterial properties helps Epoxy resin be used in the medical industry. They are manufactured into medical products used in minor surgeries..

EuroPlas has sent you the most detailed information about Epoxy resin as well as the answer to the question "Is Epoxy resin toxic". Continue to follow EuroPlas Blog to update the next exciting information!