Currently, PC plastic is very popular on the market. Industrial plastic lines are widely used in the production of household appliances.They appear a lot in human life. However, many families are still skeptical about the health safety of this material. In this article, EuroPlas will provide you with the most complete answer about the characteristics and impacts of PC plastic. Let’s take a look.

PC plastic billet

1. Overview of PC plastic

First, let's find out what polycarbonate plastic is. The scientific name of PC plastic is Polycarbonate. This line of industrial plastic is quite flexible, has no fixed shape, and exists in a transparent state. Besides, Polycarbonate plastic has no odor or color. In particular, PC plastic belongs to industrial plastic group number 7.

The ASTM International Standards Organization has classified PC plastic in industrial plastic group number 7 because this is the only type of plastic that does not have a complete identification code. Therefore, if you see plastic products such as food boxes and bottles without symbols or the number 7, these products are made from PC plastic and contain BPA.

Meanwhile, Polycarbonate is known as a synthetic plastic formed through tight bonds of carbonate groups. This is also the compound used to coat the surface of household objects. PC plastic is easy to manipulate into many different shapes because of its flexibility, stability, and poor heat resistance.

PC plastic possesses the following fundamental indicators:

- Estimated density is about 1.18 to 1.20g/cm3.

- Shrinkage is approximately 0.8%.

- The casting temperature is within the range of 230 - 320 degrees Celsius.

- Drying conditions are estimated at 60 - 120 degrees Celsius.

- Durability and load capacity are about 55 - 75 MPa.

PC plastic is easy to manipulate into many different shapes because of its flexibility, stability, and poor heat resistance.

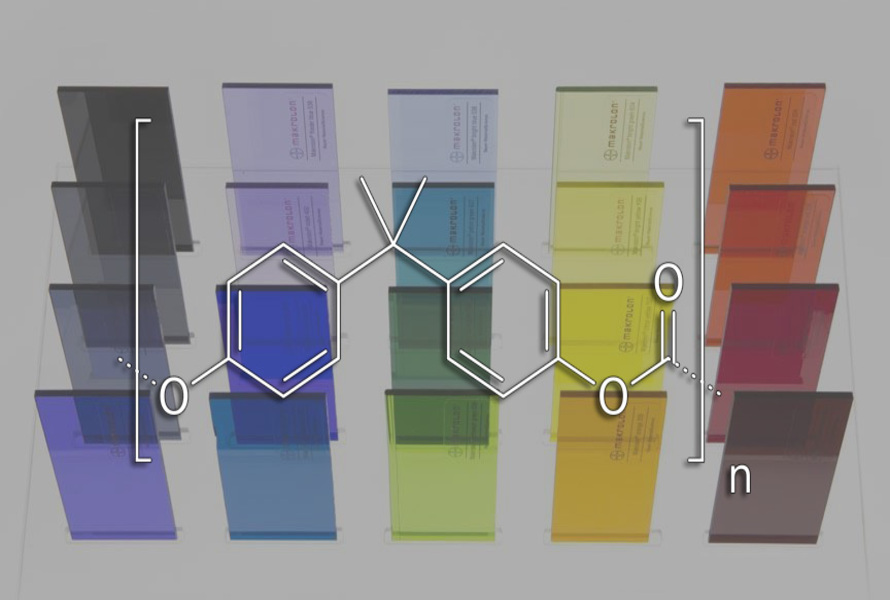

2. What is PC plastic material?

The main components that make up PC plastic No. 7 include:

Bisphenol A - BPA: This chemical compound is produced from Phenol and Acetone, with the chemical formula C15H16O2.

Carbonate: Chemical substance with the formula CO₃²⁻ and is the main component of the Polycarbonate Polymer structure.

After going through the preparation process in the laboratory, the two compounds above will combine to form long polycarbonate chains. This chain then continues to develop direct connections with esters to include PCs.

Typically, PC plastic will be more complicated than other household plastics because of the properties of BPA.

In particular, if you compare the durability of PC plastic to glass and Acrylic, this type of plastic will significantly dominate. Specifically, PC plastic is 250 times more durable than regular glass. In the next part, EuroPlas will send you PC plastic's properties and specific characteristics.

PC plastic will be more complicated than other household plastics because of the properties of BPA

PC plastic will be more complicated than other household plastics because of the properties of BPA

3. Characteristics and properties of polycarbonate plastic

The characteristics of PC plastic are similar to Polymethyl Methacrylate plastic with the symbol PMMA - this is a commonly used plastic line in the form of pieces or plates and can replace glass or glass very well due to its high durability. However, PC plastics are still better because they can withstand high loads and have higher durability, even when directly exposed to harsh environments or high temperatures.

Furthermore, PC plastic's outstanding characteristics are demonstrated by its ability to transmit light better than other types of glass on the market. Although Polycarbonate plastic is highly durable, scratch resistance upon impact is the core weakness of this material.

In addition, PC plastic also possesses many outstanding characteristics and properties that help it be fully utilized in the production of daily consumer products, serving customers' lives, for example:

- If you compare gas and vapor resistance, PC plastic is better than common industrial plastics such as PVC and PE. However, they are lower than PET and PP plastics.

- Besides, the mechanical durability and hardness of PC plastic are pretty high. This factor is combined with stable wear resistance. Because of this, Polycarbonate plastic is not affected by food ingredients.

This is the reason why PC plastic is also used to produce everyday consumer products such as cups, glasses, or plastic bottles.

Compare PC-plastic and Acrylic sheet

Furthermore, experts have commented that Polycarbonate plastic is one of the industrial plastics resistant to the effects of chemicals. For instance:

- Pure water: As we all know, PC plastic does not absorb or decompose in water.

- Inorganic chemicals: Chemicals such as weak alkalis or acids are not capable of affecting the stable material structure of PC plastic.

- Organic chemicals: In particular, common compounds such as organic solvents, oils, and greases do not react chemically with this type of plastic.

- Oxidizing agents: Although PC plastic can withstand the effects of common oxygen substances, the material still experiences decomposition or loss of transparency when exposed to strong oxidizing agents such as Ozone and Hydrogen.

To optimize performance and use PC plastic in the safest way, you also need to pay attention to the temperature resistance of this material:

- 145 - 150 degrees Celsius is the softening temperature.

- 135 - 140 degrees Celsius is the cracking temperature of PC plastic.

- 155 degrees Celsius is the average temperature to liquefy this type of plastic.

The chemical structure of PC plastic

Overall, PC plastic possesses a variety of characteristics and quite high applicability in life. EuroPlas will also re-emphasize the important properties of this industrial plastic. As follows:

- PC plastic has stable characteristics of hardness, color neutrality as well as relatively high insulating properties.

- However, Polycarbonate plastic also easily decomposes when exposed to too high temperatures and interacts quite weakly with other types of plastic. That's why manufacturers recommend that we should not use boiling water with plastic bottles, jars or cups.

- Besides, the shrinkage rate of PC plastic molds is not too high and the moisture absorption rate is low. PC plastic also needs to be dried at the right temperature and avoid too much contact with water.

- For common household PC plastic products, you can determine the proportion of Polycarbonate ingredients by observing the numbers written on the body of the product. For example, if you see the number 58 on a cup, this means that the product is composed of 58% PC plastic.

As EuroPlas introduced at the beginning, PC plastic is one of the common materials in life. Therefore, it also possesses many outstanding advantages and meets production standards at factories.

4. Advantages of PC plastic

Besides the reasonable price, PC plastic also has many superior characteristics to serve well the production process of daily fast-moving consumer products.

4.1 Force resistance

PC plastic has relatively high flexibility and stable hardness. Usually, this material will be combined with ABS material to produce high-quality suitcases. In particular, each product line will have the density of PC plastic adjusted to a balanced level to ensure durability, resistance, and stability over a long period.

Therefore, Polycarbonate plastic is used in the construction industry. Typical products include greenhouses for livestock, windshields, noise-proof glass or window frames.

The applications of PC plastic

4.2 Durability and Stable Size

Good hardness with a stable surface size of PC plastic is formed through a drying process under appropriate temperature conditions. Therefore, PC plastic products are challenging to crack or break. Not only that, it is also rated four times higher than Acrylic and 250 times higher than glass. Besides, the color neutrality of Polycarbonate plastic is not affected by external factors such as climate and environment.

This material is also produced in electronic devices such as video recorder cases, phones, computers, electrical switches, telephones, or circuit breakers based on its durability and stable heat resistance. In particular, fire resistance level E reaches about 120 degrees Celsius.

4.3 Anti-Corrosion Properties

The durable chemical structure forms a flat and smooth product surface. Therefore, PC plastic can be used for long periods and undergo harsh weather conditions. The material also withstands some mechanical impacts at a relative level.

That is why PC plastic is also used to produce equipment for long-distance cars or trucks. It has durability over time, helping to reduce the vehicle's weight, and maximizes aerodynamics.

PC plastic easily blends colors

4.4 Aesthetics

As we all know, PC plastic is transparent so you can easily combine and mix with other colors during the production process. Furthermore, the flexible nature of PC plastic helps factories easily form many products to serve human life. After mixing, the color of the material is maintained for a long time and minimizes discoloration due to environmental factors.

Although PC plastic possesses many outstanding advantages compared to conventional plastic materials, experts often recommend limiting the use of PC plastic products as much as possible. Do you know the reason why PC plastic is toxic? Right now, EuroPlas will answer that question.

5. Is PC plastic toxic?

Firstly, the core nature of PC plastic or Polycarbonate plastic is completely non-toxic and does not affect human health. However, the biggest problem is the production stage of this material. During this period, PC industrial plastic materials will have a very high possibility of producing the compound Bisphenol A or BPA and there will be 2 cases:

The finished product will not contain BPA if this compound completely transforms into a flexible structure under the influence of temperature during the long production process. This means that the product meets standards and is safe for humans.

The transformation of the chemical compound BPA will make PC plastic toxic

Suppose a small amount of BPA does not qualify for conversion and exists in solid form and passes through the structure of PC plastic. In that case, the product will affect consumer health because BPA is identified as a compound that increases cancer risk.

However, you don't need to worry too much because BPA cannot spread or accumulate in a short time. Therefore, manufacturers only use PC plastic for disposable products. In addition, you need to carefully check plastic products at home. If they have the symbol number 7 or do not have any symbols, we should not reuse them many times.

6. Methods of handling toxic PC plastic

You should not destroy toxic PC plastic products like plastic number 7 because they are tough to decompose and harm the environment. Instead, it would help if you used them to store gasoline, oil, or other household waste. If you live in a rural area, you can recycle them into animal feed containers. You must not use them in food processing or preservation; toxins will increase when exposed to hot food.

Experts also recommend that there are 3 types of plastic that should be used in the home:

Before using, you also need to clean all plastic products thoroughly. However, you should only use cold water and prohibit the use of warm water as well as solutions containing solid detergents such as Chloride and Ketone. You should not leave plastic products in locations close to heat sources such as rice cookers, microwaves or sunlight.

7. Introduction of EuroPlas' PC glass fiber & flame-retardant compound

PC glass fiber & flame-retardant compounds are two quite popular product lines in EuroPlas' portfolio and are manufactured in accordance with international standards. Let's learn briefly about them!

7.1 PC flame retardant compound

The product line is combined with a flame retardant additive called Halogen. PC flame retardant compound (PC-FR) is provided by EuroPlas according to 5 UL94 standard fire resistance levels: 5VA, 5VB, V0, V1, V2.

These are safety-tested compounds for applications that require advanced safety features, such as portable chargers, keyboards, power outlets, electronic components, and headsets.

- PC-FR plastic products at EuroPlas bring together the following advantages

- Minimize the spread of fire.

- Specially designed according to the characteristics of the finished product.

- EuroPlas can directly process finished products without mixing with any raw materials. This ensures product purity and quality.

| PHYSICAL PROPERTIES |

ISO/METHOD |

Units |

Values |

| Melt Flow Rate (300°C/2.16kg) |

ISO 1133 |

g/10 min |

34 |

| Density |

ISO 1183 |

g/cm³ |

1.21 |

| Mold Shrinkage |

ISO 294 |

% |

0.4 – 0.7 |

| MECHANICAL |

|

|

|

| Tensile Strength at Yield |

ISO 527 |

MPa |

62 |

| Tensile Modulus |

ISO 527 |

MPa |

2284 |

| Elongation at Yield |

ISO 527 |

% |

>10 |

| Flexural Strength |

ISO 178 |

MPa |

84 |

| Flexural Modulus |

ISO 178 |

MPa |

2324 |

| Charpy Impact Strength, Notched |

ISO 180 |

J/m |

105 |

| Izod Impact Strength, Notched |

ISO 180 |

J/m |

105 |

7.2 PC glass fiber compound

The main component of this product line is glass fiber, which is considered an indispensable reinforcing material in the structure of PC-GF plastic.

Therefore, PC glass fiber compound possess impact resistance and maintain stable size for a long time. The mechanical properties of tensile and bending strength of this material are also remarkable.

Europlas' PC-GF product ensures different proportions of glass fibers to give them the most specific mechanical properties. The material is used in the production of keyboards, gears, printers, cameras, vacuum cleaners or rice cookers.

| PHYSICAL PROPERTIES |

ISO/METHOD |

Units |

| Color |

|

Natural |

| Glass fiber content |

TGA |

% |

| Density |

ISO 1183 |

g/cm³ |

| MECHANICAL |

|

|

| Tensile Strength at Yield |

ISO 527 |

MPa |

| Elongation at Break |

ISO 527 |

% |

| Flexural Strength |

ISO 178 |

MPa |

| Flexural Modulus |

ISO 178 |

MPa |

| Izod Impact Strength, Notched |

ISO 180 |

J/m |

EuroPlas has provided the most detailed information about the PC plastic line and answers, "Is PC plastic toxic?". The article shows this material's characteristics, applications, and core properties. Continue to follow EuroPlas to update the latest news about plastic products!