MC plastic is a versatile industrial material used in a wide range of modern industries. With its superior durability and heat resistance, MC plastic is gradually replacing traditional materials. However, understanding this material and its potential applications can be challenging. This article provides a clear and concise explanation of MC plastic, from its definition to its various uses, helping you grasp the potential of this popular material.

1. Definition of MC Resin

MC resin, also known as Monomer-Cast Nylon or Cast PolyAmide, is a type of thermoplastic. Its primary component is nylon 6, derived from caprolactam containing six carbon atoms. The production process of MC resin involves using an alkaline compound as a catalyst and melting caprolactam to create a polymer mixture, resulting in a material with many superior properties.

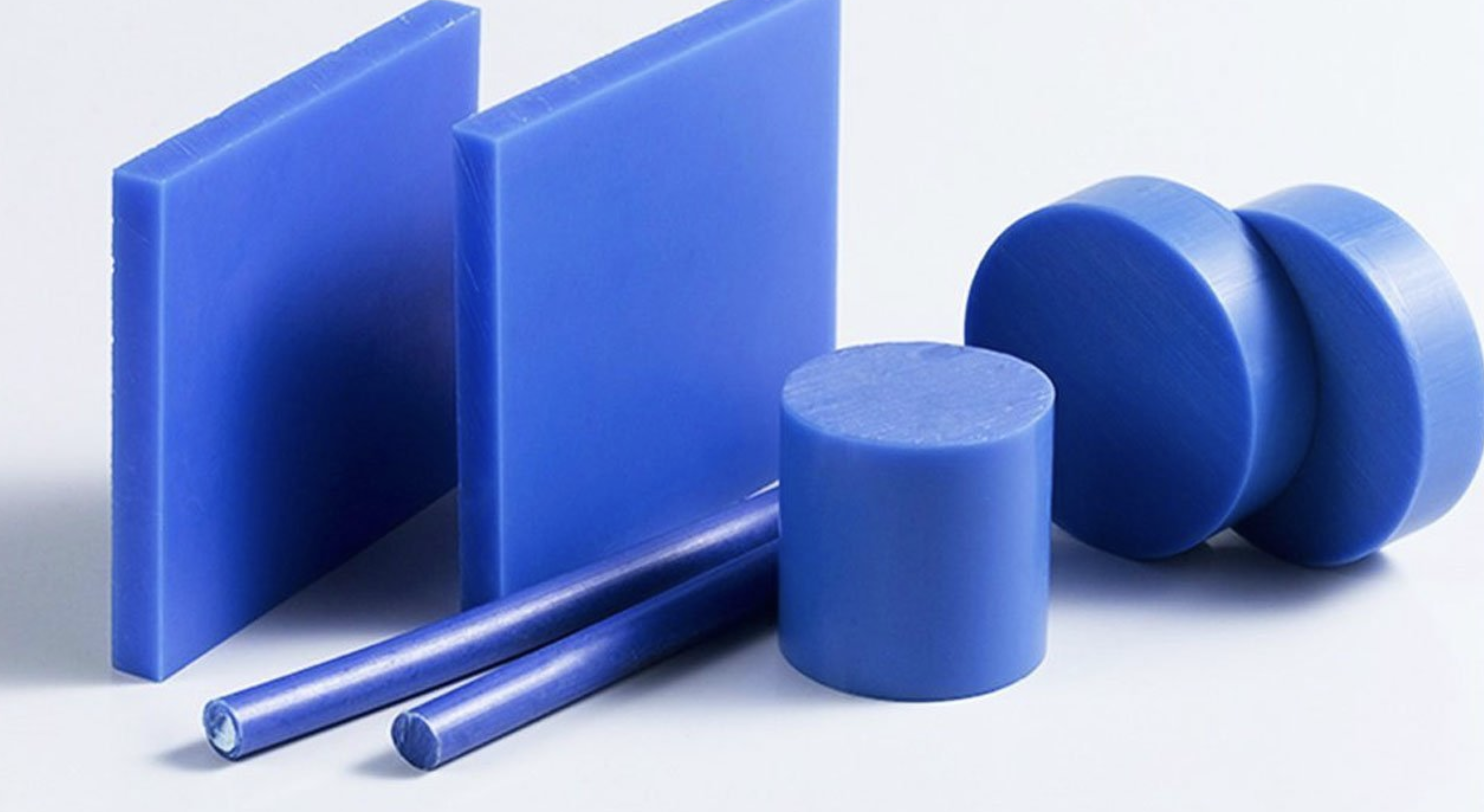

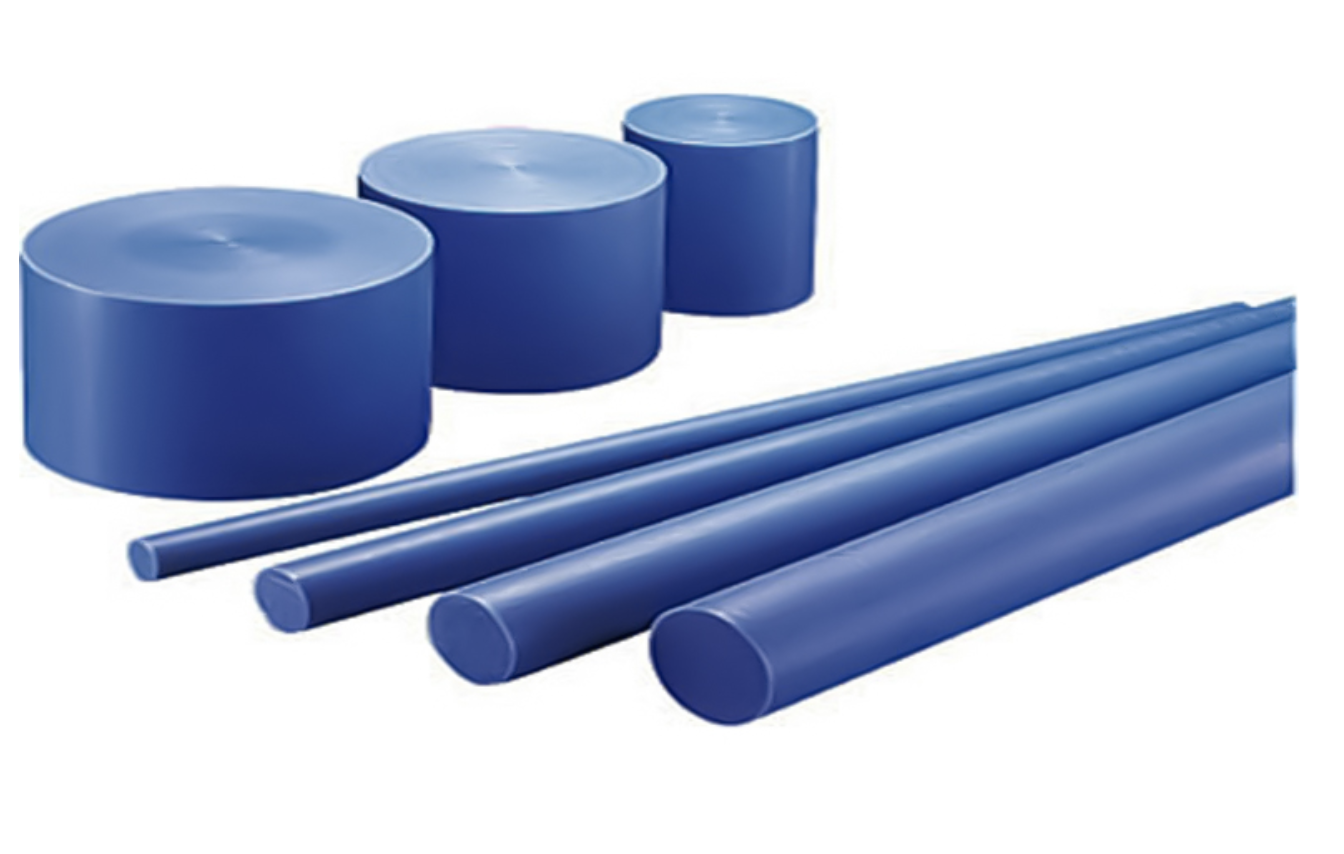

MC resin can be classified based on two main criteria: shape and physical properties. Specifically:

- MC sheet: Common sizes range from 1000x2000mm or 1000x1000mm and thickness from 5mm to 80mm.

- MC rod: Standard length is 1000mm and diameter ranges from 6mm to 300mm.

- Classification by physical properties:

- Standard type

- Anti-static type

The main colors of MC resin are green, black, and milky white. However, the diversity of MC resin goes beyond shape and color. The market offers various variants and applications of MC resin, including standard MC Nylon, MC resin from Korea and China, MC sheet and rod, MC bar, MC resin in different colors, MC 501 (special type), solid and hollow MC rods, as well as static and anti-static MC resin.

In conclusion, MC resin is a crucial industrial material that can meet diverse needs due to its variety of shapes, sizes, and properties. With numerous advantages and wide-ranging applications, MC resin has played a significant role in many modern manufacturing and fabrication sectors.

2. Properties of MC Resin

MC resin possesses numerous outstanding properties, making it a preferred choice for many industrial applications:

- Extremely lightweight: MC resin weighs only 1/7 of metal, significantly reducing the weight of products and equipment.

- Easy to process: MC resin can be easily shaped, cut, and processed into various forms, providing flexibility in manufacturing.

- Impact and noise resistance: This property makes MC resin suitable for applications requiring noise reduction and the ability to withstand physical impacts.

- Corrosion resistance and high durability: MC resin can resist corrosion from a wide range of chemicals and harsh environments, while maintaining high durability over long periods of use.

- Excellent electrical insulation and cost-effectiveness: MC resin is an excellent electrical insulator and is also cost-effective, making it a cost-saving option for many industrial applications.

- Resistance to organic solvents and water leakage: This property makes MC resin suitable for applications involving contact with various solvents and liquids.

See more: 5 common fire resistant plastics and how to enhance plastic fire resistance

3. Applications of MC Resin

The exceptional properties of MC resin have led to its widespread adoption across a broad spectrum of industries:

- Electrical equipment: Manufacturing gears and rollers for electrical equipment.

- Automotive industry: Producing wheels, rollers, and pump components for automobiles; manufacturing wheel components such as bushings, studs, and wear-resistant parts.

- Medical and food industries: Producing components for medical equipment and food processing machinery.

- Textile industry: Manufacturing gears, thread tubes, bobbins, and guide rods for textile machinery.

- Other industries: Application in chemical engineering, paper and pulp production; use in civil construction and electrical equipment; application in shipbuilding, automotive, and aerospace.

- Mold and machine part manufacturing: Making dies, machine feet, and other machine parts.

- Steel and construction industry: Application in equipment and machinery of the steel and construction industry.

- Transportation and logistics industry: Manufacturing wheels, conveyor rollers, sprockets, and pallets for transportation and handling equipment.

- Mechanical and metalworking industry: Processing shaft components for rollers and protective parts in metal and steel machines; manufacturing components such as gears, rollers, and other wear-resistant parts.

- Packaging and paper manufacturing industry: Used as spacers in the packaging and paper manufacturing industry.

- Shipbuilding, automotive, and aircraft industry: Used in the manufacturing of components and parts for ships, vehicles, and aircraft.

- JIG and automation manufacturing industry: Application in the production of jigs, machine tooling, and automation systems.

In summary, MC resin is a versatile industrial material with numerous superior properties. From its high heat resistance to its mechanical strength and inherent flame resistance, MC resin has proven its value in many industries. The wide range of applications of MC resin not only demonstrates the versatility of this material but also highlights its future development potential. As industries continue to demand higher-performing, safer, and more environmentally friendly materials, MC resin is poised to play a vital role in meeting these needs.

4. Conclusion

MC resin has proven indispensable in numerous modern industrial applications. With outstanding properties such as lightweight, impact and noise resistance, easy processing, corrosion resistance, and high durability, MC resin has become the preferred choice for a wide range of applications.

From mechanical engineering, transportation, and electronics to textiles, and even high-tech fields like aerospace and shipbuilding, MC resin is present and plays a crucial role in the development of these industries. The broad applicability of MC resin not only optimizes production processes but also enhances the quality of final products.

A thorough understanding of the properties and applications of MC resin will enable businesses, engineers, and manufacturers to fully exploit the potential of this material. In the future, with the continuous development of technology, we can expect to see more innovative and advanced applications of MC resin, further solidifying its importance in modern industry.

However, it is important to note that, like all synthetic materials, the use of MC resin requires careful consideration of environmental impacts. Although it offers numerous advantages, the thermosetting nature of MC resin also means that it is difficult to recycle, necessitating special disposal methods.

Future research on MC resin may focus on improving its recyclability and reducing its environmental impact, while also exploring new applications in advanced technologies. With ongoing advancements in materials science, MC resin is poised to continue playing a significant role in shaping the future of industry and technology.

5. About EuroPlas

EuroPlas has established itself as a world-leading supplier of filler masterbatch products. Beyond its current position, EuroPlas is continually innovating and developing high-quality products to meet the diverse needs of the global market.

Furthermore, EuroPlas has been at the forefront of combining MC resin with other polymers to create unique blends with superior properties. This not only enhances product quality but also expands the range of applications in various industries.

Through continuous innovation and a commitment to quality, EuroPlas has solidified its position as a pioneer in the application and development of MC resin, making significant contributions to the growth of the plastics industry and the filler masterbatch sector in particular. If you require further information about MC resin and filler masterbatch products, please contact EuroPlas or fill out the form, and we will get back to you shortly.