Polycarbonate (PC) is a high-performance thermoplastic known for its strength, clarity, and thermal resistance. It's widely used in industries ranging from automotive to electronics, construction to medical equipment. But to fully understand what makes PC so versatile, one must explore one of its defining characteristics: the PC melting point.

In this article, we’ll explore what the PC melting point is, how it affects manufacturing processes, how it compares to other plastics, and where this knowledge plays a critical role in real-world applications.

Read more:

1. What is the PC melting point?

Unlike crystalline plastics, polycarbonate is an amorphous thermoplastic, which means it doesn’t have a sharp, singular melting point. Instead, it softens gradually over a temperature range. For PC, the material typically begins to soften around 147°C (297°F) and reaches its glass transition temperature (Tg) at approximately 150°C (302°F). This is the point at which the polymer transitions from a rigid state to a rubbery, deformable one.

However, in processing and practical use, polycarbonate is usually heated to between 250°C and 300°C to achieve proper flow during extrusion or injection molding. These higher temperatures ensure the material is pliable enough for complex shaping and mold filling.

What is the PC melting point?

2. Why the PC melting point matters in manufacturing

The PC melting point is a vital factor in determining how the material behaves during fabrication. Too little heat and the plastic won’t fill the mold properly, leading to incomplete or fragile parts. Too much heat and the polymer chains may begin to degrade, resulting in discoloration, warping, and compromised performance.

Understanding this melting range is essential in injection molding, extrusion, and 3D printing. In injection molding, for example, barrel temperatures are often maintained between 270°C and 320°C, with mold temperatures held around 80°C to 120°C for optimal cooling and demolding.

In 3D printing (FDM), PC filament requires higher temperatures than common plastics like PLA. The extruder must reach 270°C to 310°C, and the print bed often needs to be heated to 100°C or more to avoid warping. This makes PC a challenging but highly rewarding material in additive manufacturing.

3. How the PC melting point affects performance

The PC melting point plays a vital role in determining the thermal endurance, mechanical strength, and long-term dimensional stability of polycarbonate-based products. Because of its relatively high softening range, polycarbonate maintains its rigidity and form in high-heat environments—making it a preferred choice in demanding technical applications.

For example, in the automotive lighting sector, polycarbonate melting point performance ensures that headlamp housings retain their shape and clarity when exposed to high engine heat or prolonged sunlight. The ability to resist thermal deformation is essential for sustaining light quality and extending product life cycles. In electronics, PC is used for components such as laptop covers and mobile phone enclosures, which are regularly exposed to heat from processors or charging systems. Here, the PC melting point prevents material warping, contributing to both protection and aesthetics.

Another notable advantage is dimensional stability under thermal stress. Unlike plastics that expand or warp easily with temperature changes, polycarbonate maintains its dimensions, making it highly suitable for applications that require consistent form and fit—such as medical visors, bulletproof windows, and equipment housings for sterilized environments.

The PC melting point plays a vital role in determining the thermal endurance of polycarbonate-based products.

4. Comparing PC melting point with other plastics

Understanding the PC melting point is easier when compared to the thermal characteristics of other common thermoplastics.

ABS, for instance, has a glass transition temperature of about 105°C, making it easier to mold but unsuitable for high-heat applications. PETG softens at approximately 85°C and melts near 230°C. While it offers decent chemical resistance, it falls short in environments requiring sustained heat resistance.

Nylon offers a higher melting point than polycarbonate—above 200°C—but its moisture absorption properties can affect dimensional stability and product integrity. Polypropylene (PP) has a melting point around 160°C but exhibits poor impact strength, especially at low temperatures.

In contrast, polycarbonate melting point behavior demonstrates a well-balanced profile. While it doesn’t have a sharp melt point due to its amorphous nature, its high softening range (around 150°C) combined with excellent impact resistance and optical clarity make it ideal for both functional and aesthetic applications. This balance gives PC a competitive edge in markets demanding performance under thermal, mechanical, and optical stress.

5. Applications where PC melting point is critical

There are numerous industries where managing the PC melting point is essential for reliable product performance. In the automotive sector, polycarbonate isn’t only used for lights—it also appears in dashboards, sunroof assemblies, and center console parts, all of which endure fluctuating temperatures and mechanical stress. Its lightweight profile further supports energy efficiency and emission compliance efforts.

In medical device manufacturing, PC is employed in IV fluid containers, surgical trays, diagnostic tool housings, and oxygen masks. These applications require resistance to autoclave sterilization—often exceeding 120°C. Thanks to the polycarbonate melting point, these components can maintain structural integrity and visual clarity even after repeated sterilization cycles.

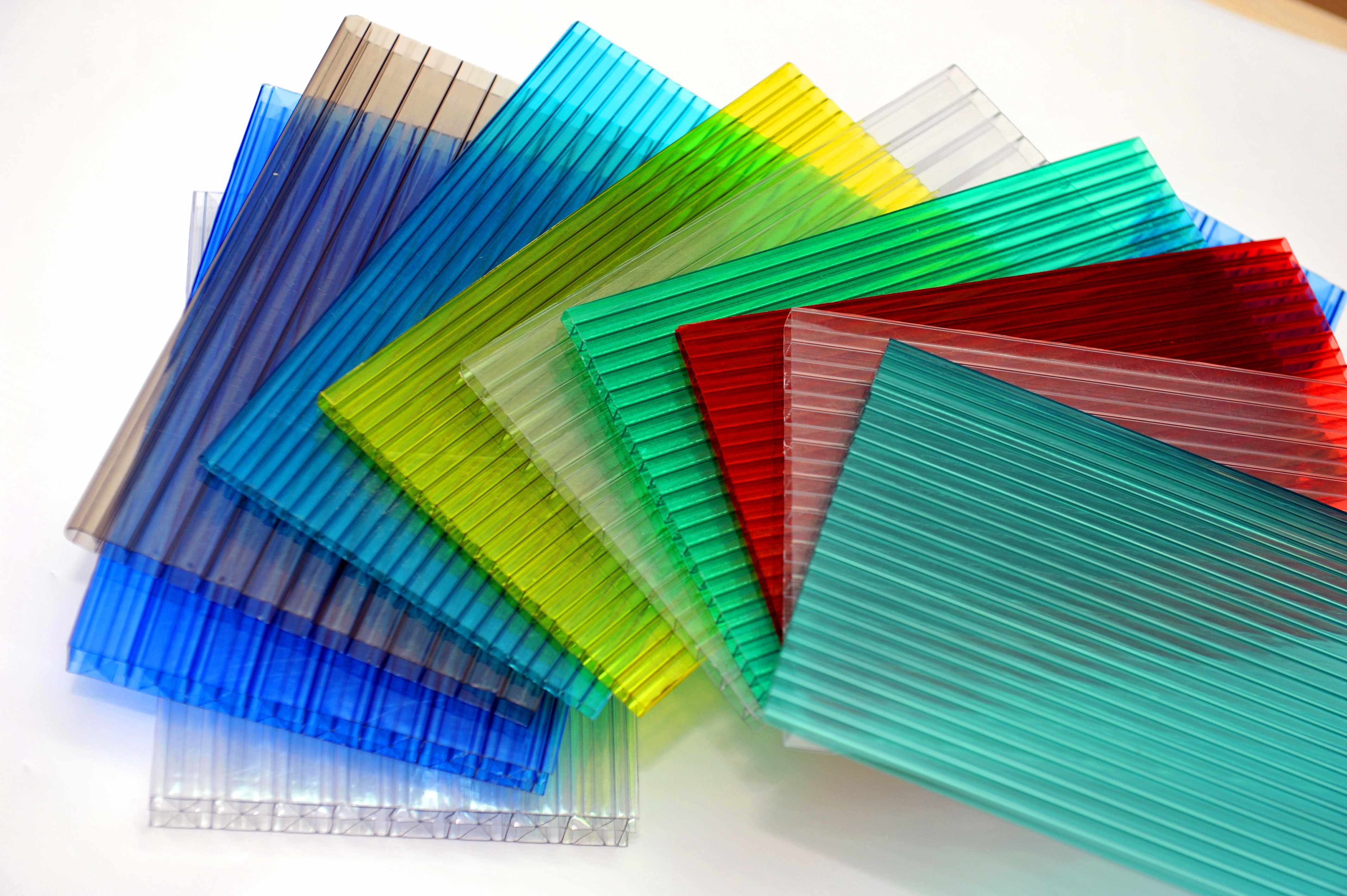

The construction industry also benefits from PC’s high-heat capabilities. PC sheets are used in skylights, greenhouse panels, and transparent roofing solutions. These installations demand not only mechanical strength but also long-term exposure to sunlight and temperature fluctuations. PC’s thermal stability and optional UV protection coatings make it an excellent choice for exterior and semi-exterior architectural use.

Consumer electronics represent another field where the PC melting point provides key advantages. Whether in smartphones, laptops, or optical media, polycarbonate’s ability to maintain shape and protect internal systems from moderate heat ensures device longevity and reliability. The material also allows for high-gloss surface finishes and color customization, enhancing product aesthetics alongside performance.

6. Challenges in processing polycarbonate

Despite the advantages of the PC melting point, this very property creates specific processing challenges. High temperatures require precise thermal control. Overheating the resin can lead to polymer chain degradation—resulting in discoloration, reduced impact strength, or the appearance of bubbles. Conversely, if heating is insufficient, polycarbonate may not flow adequately, leading to incomplete mold fills and compromised component integrity.

Moisture sensitivity is another critical concern. PC is hygroscopic, meaning it readily absorbs moisture from the air. Before processing, the resin must be dried at around 120°C for 3–5 hours. Failure to do so can result in water vapor forming bubbles during molding, which weakens the finished product and affects surface appearance.

Cooling rates also need careful management. Polycarbonate cools slower than many other plastics, which can prolong cycle times in injection molding operations. Efficient mold designs with optimized cooling channels are essential to maintain productivity without sacrificing quality.

Moreover, the equipment used to process PC must be capable of withstanding prolonged high-temperature operation. This raises initial investment and maintenance costs, and also increases energy consumption. However, in industries that prioritize durability and high-performance outputs, these trade-offs are widely accepted.

Despite the advantages of the PC melting point, this very property creates specific processing challenges.

7. Conclusion

The PC melting point is not a single temperature but a range that significantly impacts how polycarbonate is processed, where it can be used, and how it performs under stress. Its high softening point, combined with strength, clarity, and dimensional stability, make it an ideal material for industries requiring durability and precision under heat.

As technologies advance and performance requirements grow stricter, the importance of understanding thermal behaviors like the PC melting point becomes even more essential for engineers, manufacturers, and product designers.

8. About EuroPlas

EuroPlas is one of the world’s leading manufacturers of plastic compounds and masterbatches, operating seven modern plants across Vietnam and Egypt with a total annual capacity of 800,000 tons. Our products are trusted in over 95 countries worldwide.

In our portfolio of engineering plastics, EuroPlas offers flame-retardant PC compounds—polycarbonate-based materials combined with halogen flame-retardant additives—as well as glass fiber-reinforced PC compounds. These are designed to provide enhanced tensile strength, impact resistance, and thermal stability. These features make our PC compounds ideal for high-performance applications, ensuring durability, reliability, and safety for your products.

If you’re looking for a trusted partner in innovative polycarbonate solutions, get in touch with EuroPlas.