In industrial environments where extreme temperatures, volatile chemicals, and high voltages are the norm, insulation materials play a critical role. They not only ensure the efficiency and safety of operations but also extend the lifespan of machinery and infrastructure. From protecting electrical systems to minimizing heat loss in pipelines, insulation solutions are the unsung heroes of industrial design.

Among the vast array of options, plastic insulation materials have gained traction for their unique combination of durability, flexibility, and affordability. But with so many types available—each suited to specific needs—choosing the right one can be challenging. This article explores the top plastic insulation materials used across industries, highlighting their strengths, applications, and considerations to help you make informed decisions.

Read more: What Are Insulating Plastics? Properties & Applications

What Are Insulation Materials?

1. Why Insulation Is Crucial in Industrial Applications

1.1. Functions of Insulation: Thermal, Electrical, Acoustic

In an industrial setting, insulation is far more than a simple heat barrier. It performs three essential roles:

- Thermal insulation: Reduces heat transfer between surfaces, essential for energy conservation in HVAC systems, boilers, furnaces, and piping.

- Electrical insulation: Prevents current leakage in wiring and equipment, protecting both systems and personnel from electrical hazards.

- Acoustic insulation: Minimizes noise pollution from heavy machinery, contributing to workplace safety and comfort.

Each function may require a different material type, depending on the operating environment and technical demands.

1.2. Impact on Safety, Energy Efficiency, and Equipment Lifespan

According to a report by Grand View Research, the global industrial insulation market was valued at USD 2.8 billion in 2021 and is expected to grow significantly by 2030, driven by energy efficiency mandates and industrial automation trends.

Effective insulation materials can:

- Reduce energy loss by up to 25% in thermal systems

- Lower operational risks such as fires, electrical faults, or thermal degradation

- Prolong equipment service life, reducing maintenance costs and downtime

These benefits make insulation a strategic investment for any industrial facility.

2. How Plastic Insulation Materials Work

Plastics may not be the first materials that come to mind for insulation, but their engineering-grade properties make them ideal for industrial insulation—especially in applications that require lightweight, moldable, and corrosion-resistant solutions.

2.1. Heat Resistance and Low Thermal Conductivity

Unlike metals, which are highly conductive, most plastics are natural thermal insulators. Their molecular structure restricts the free flow of heat, making them perfect for insulating surfaces where thermal regulation is crucial.

For example, expanded polystyrene (EPS) has a thermal conductivity as low as 0.03 W/m·K, making it suitable for use in wall panels and cold storage.

2.2. Electrical Insulation Capacity of Plastics

Many thermoplastics, such as PVC, PP, and PE, have high dielectric strength—meaning they can withstand high voltages without breaking down. This property makes them ideal for cable sheathing, circuit components, and connector housings. In fact, PVC is used in over 50% of all cable insulation applications globally, thanks to its strong insulating ability and flame retardant characteristics.

2.3. Mechanical Strength and Corrosion Resistance

Plastics used for insulation also offer robust mechanical integrity, allowing them to endure pressure, bending, or mechanical stress—unlike traditional insulators like fiberglass or ceramics which can be brittle. Additionally, plastics such as polypropylene (PP) resist corrosion from chemicals, acids, and solvents—making them suitable for industrial piping and chemical storage.

How Plastic Insulation Materials Work

3. Top Plastic Insulation Materials in Industry

Below are the most widely used plastic insulation materials in industrial environments, along with their distinctive advantages and application areas.

3.1. Polyethylene (PE) – Lightweight and Water-Resistant

Polyethylene, especially cross-linked polyethylene (XLPE), is prized for its:

- Low thermal conductivity (~0.4 W/m·K)

- Excellent moisture resistance

- High flexibility and toughness

Applications: PE is commonly used in insulated pipes, ducting, and flexible wiring, especially in underground or damp environments.

3.2. Polypropylene (PP) – Durable and Chemical-Resistant

PP is a semi-crystalline thermoplastic with:

- High chemical resistance

- Good thermal insulation properties

- Superior mechanical durability

Applications: PP is used in chemical process tanks, piping, and low-voltage electrical insulation, especially where exposure to chemicals is frequent.

3.3. Polyvinyl Chloride (PVC) – Excellent Electrical Insulation

One of the most versatile plastics, PVC provides:

- High dielectric strength (up to 40 kV/mm)

- Fire-retardant capabilities

- Ease of processing and low cost

Applications: PVC is widely used in wire and cable insulation, electrical conduit, and switchgear enclosures.

3.4. Polystyrene (PS) – Thermal Insulation for Buildings

Expanded and extruded polystyrene (EPS and XPS) are known for:

- Extremely low thermal conductivity (~0.03–0.04 W/m·K)

- Lightweight and compressive strength

- Low water absorption

Applications: Frequently used in building insulation panels, refrigeration units, and packaging for temperature-sensitive goods.

3.5. Polyamide (Nylon) – High Strength and Heat Resistance

Polyamide, commonly known as Nylon, stands out for:

- Exceptional tensile strength

- Good thermal and electrical insulation

- Resistance to wear and friction

Applications: Common in electrical connectors, gears, and motor housings, especially in automotive and electrical industries.

3.6. PEEK – Advanced Solution for Extreme Conditions

Polyetheretherketone (PEEK) is an advanced engineering plastic offering:

- Withstand temperatures up to 260°C

- High chemical and electrical resistance

- Outstanding dimensional stability

Applications: PEEK is used in aerospace, oil & gas, and high-performance electrical systems, where ordinary plastics would fail.

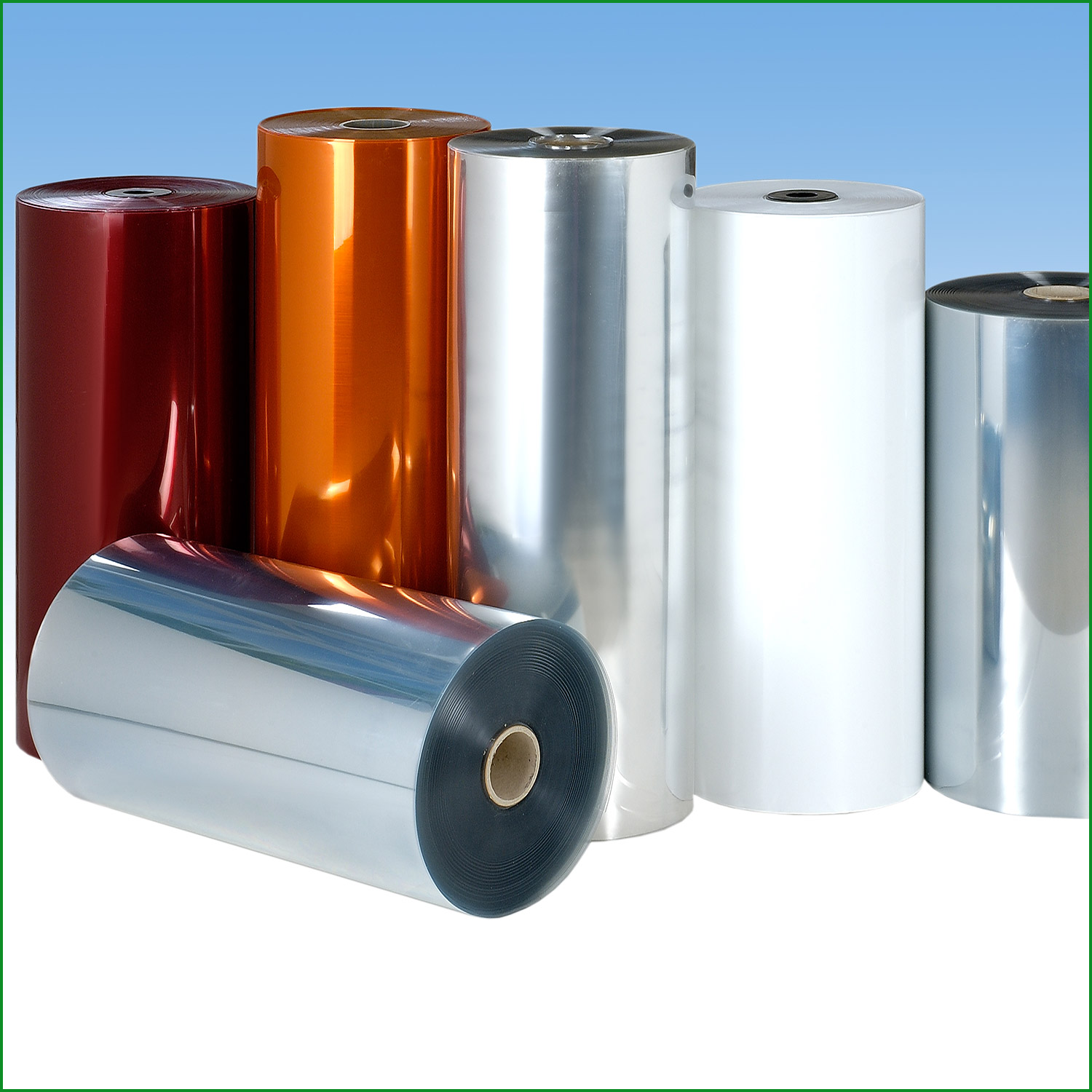

Top Plastic Insulation Materials in Industry

4. Comparison Table of Insulation Plastics

4.1. Compare Temperature Range, Cost, Flexibility, and Applications

To help visualize the differences among top plastic insulation materials, the table below summarizes key attributes:

| Material |

Thermal Resistance |

Electrical Insulation |

Chemical Resistance |

Flexibility |

Typical Applications |

| PE |

Up to 90°C |

Moderate |

High |

High |

HVAC, underground piping |

| PP |

Up to 100°C |

Moderate |

Excellent |

Medium |

Tanks, piping, insulation sheathing |

| PVC |

Up to 105°C |

High |

Good |

Medium |

Cables, wiring, conduit |

| PS (EPS/XPS) |

Up to 80°C |

Low |

Poor |

Low |

Building panels, packaging |

| Nylon |

Up to 120°C |

High |

Good |

Medium |

Electrical connectors |

| PEEK |

Up to 260°C |

Excellent |

Excellent |

Low |

Aerospace, high-heat systems |

4.2. Quick Guide to Choose the Right Plastic Insulator

- For cost-sensitive applications: PE or PP

- For electrical systems: PVC or Nylon

- For thermal protection in structures: EPS/XPS

- For extreme heat and harsh chemicals: PEEK

Always consult with a materials expert or supplier to ensure the selected material meets your exact performance and regulatory requirements.

5. Factors to Consider When Choosing Insulation Materials

5.1. Operating Temperature

Different materials perform optimally at specific temperatures. For high-heat environments like foundries or oil refineries, PEEK or Nylon may be appropriate, while PE or PS might suffice for lower-temp HVAC applications.

5.2. Environmental Exposure

If the material is exposed to moisture, oils, UV light, or corrosive chemicals, prioritize plastics with strong resistance such as PP or PVC. Also consider UV-stabilized grades if used outdoors.

5.3. Load-bearing Requirements

When insulation must also support structural loads, like in equipment housings or pipe supports, select materials with high mechanical strength, such as Nylon or PP.

5.4. Budget and Sourcing Considerations

Cost is often a deciding factor in large-scale installations. While premium materials like PEEK deliver unmatched performance, common alternatives like PE or PVC may strike a better balance between price and functionality, especially in moderate-use cases.

Pro tip: For high-volume purchases, consider sourcing directly from OEM manufacturers or certified plastic suppliers to reduce cost per unit and ensure quality.

6. Trends in Industrial Insulation Materials

The insulation market is rapidly evolving in response to new sustainability demands, technology integration, and regulatory pressures.

6.1. Sustainable and Recyclable Insulation Plastics

Eco-conscious industries are shifting toward bio-based and recyclable plastics, such as bio-PE or recycled PP, to reduce environmental impact without compromising performance.

6.2. Smart Insulation Materials (with Sensors, Adaptive Behavior)

Emerging smart insulation systems now integrate sensors to monitor:

- Heat flow

- Moisture ingress

- Material degradation over time

These systems offer predictive maintenance and remote monitoring, essential in high-value industrial assets.

6.3. Nanocomposite Polymers for Enhanced Performance

Nanocomposite materials blend plastic resins with nano-fillers like graphene or silica, resulting in:

- Improved thermal conductivity control

- Increased strength-to-weight ratio

- Better flame retardancy

Such advanced materials are gaining attention in electronics, aerospace, and military applications.

7. Conclusion

Plastic-based insulation materials have proven indispensable across a wide range of industrial sectors. Whether you prioritize thermal resistance, electrical safety, chemical durability, or cost-efficiency, there is a plastic insulator tailored to your needs. From common materials like PE and PVC to advanced polymers like PEEK, choosing the right solution requires a thorough understanding of the operating environment and performance requirements.

As industrial standards evolve, so too does the world of insulation. Staying informed about the latest innovations and sustainability trends ensures your facility remains efficient, safe, and compliant.

8. About EuroPlas

EuroPlas is one of the world’s leading manufacturers of plastic compounds and masterbatches, operating seven state-of-the-art factories across Vietnam and Egypt with a total annual capacity of 800,000 tons. Our products are trusted in more than 95 countries worldwide.

Our portfolio includes filler masterbatch, color masterbatch, plastic additives, engineering plastic compounds, and bio-based bioplastics and biofillers under the BiONext and BiOMates brand. Especially, EuroPlas' anti-static additive is used to reduce the static charge build-up on plastic surface, resulting in safer and more effective manufacturing process. With more than 15 years of experience in the plastic industry, we will help you choose the right additives based on your materials, production conditions, and applications.

EuroPlas' anti-static additive is used to reduce the static charge build-up on plastic surface.

If you're seeking advanced plastic solutions for electrical insulation or other technical needs, contact EuroPlas for more information.

9. Frequently Asked Questions (FAQ)

Q1: Which plastic insulation material is best for electrical applications?

=> PVC and Nylon are excellent choices due to their high dielectric strength. PVC is widely used for wiring and cables, while Nylon is preferred for connectors and housing.

Q2: Is PEEK worth the cost?

=> Yes—if your application demands extreme heat or chemical resistance. PEEK outperforms most plastics in aerospace, oil & gas, and high-voltage applications.

Q3: Can insulation plastics be recycled?

=> Many plastics like PE and PP are recyclable. New bio-based and recycled options are emerging, especially in line with global sustainability goals.

Q4: How do I calculate how much insulation material I need?

=> It depends on surface area, thickness, and application type. Most suppliers offer calculation tools or consultation to help estimate volume and cost.

Q5: Are plastic insulation materials safe?

=> Yes. When used correctly and within thermal/electrical limits, plastic insulators are safe and comply with international standards like UL94 and RoHS directives.