When it comes to high-performance polymers, nylon 6/10 often flies under the radar. Yet this versatile polyamide offers a unique combination of chemical resistance, low moisture absorption, and flexibility—making it a valuable material in various engineering and consumer applications. In this article, we’ll explore everything you need to know about nylon 6 10: from its molecular structure and monomers to how it compares with other types of nylon and where it’s most commonly used.

1. What is Nylon 6 10?

1.1. Overview of Polyamides

Nylon 6 10 is part of a large family of synthetic polymers known as polyamides, which are formed by the reaction of diamines and dicarboxylic acids. These materials are widely used in industries due to their strength, durability, and thermal resistance.

Nylon 6 10 falls under the aliphatic nylons, which means its structure does not include aromatic rings—this contributes to its flexibility and lower moisture absorption compared to some other nylons. Its chemical properties make it an ideal candidate for applications requiring fuel and chemical resistance.

1.2. Meaning of the Numbers “6” and “10”

The numbers in the name nylon 6 10 refer to the number of carbon atoms in each of the monomer units used to make the polymer:

- The “6” comes from hexamethylenediamine, which has six carbon atoms.

- The “10” refers to sebacic acid, a dicarboxylic acid with ten carbon atoms.

This naming system is common in polyamide chemistry and helps differentiate nylon types like nylon 6 6, nylon 6 12, and nylon 6—each with unique mechanical and chemical characteristics. Compared to nylon 6 6, nylon 6 10 has lower water absorption and better chemical resistance, making it suitable for moist or chemically aggressive environments.

Read more: Nylon 6: Definition, properties and common uses

What is nylon 6 10?

2. Chemical Structure and Monomers

2.1. Nylon 6 10 Structure

Nylon 6 10 has a repeating structure made up of amide bonds (-CONH-) that link the diamine and dicarboxylic acid units. Its structure allows for some degree of crystallinity while maintaining flexibility, resulting in:

- Good dimensional stability

- Lower density than aromatic polyamides

- A smooth surface finish, ideal for molded parts

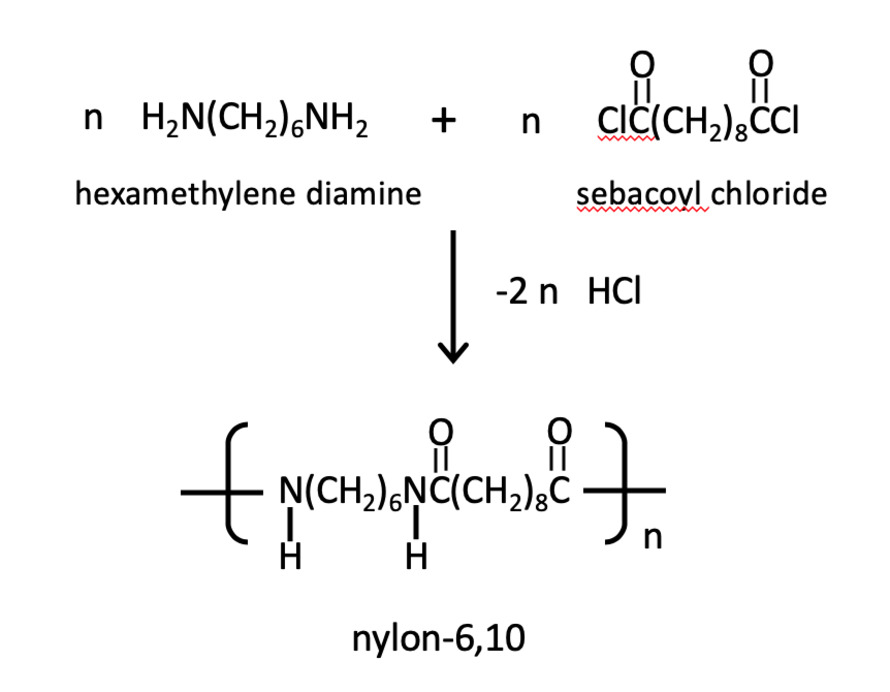

Here’s a simplified representation of the repeating unit: [–NH–(CH₂)₆–NH–CO–(CH₂)₈–CO–]ₙ

This structure contributes to nylon 6 10’s toughness and resistance to solvents, oils, and fuels—key for automotive and industrial applications.

2.2. Nylon 6 10 Monomers

Nylon 6 10 is synthesized from two monomers:

- Hexamethylenediamine (HMDA) – A linear diamine with six carbon atoms

- Sebacic acid – A naturally derived dicarboxylic acid with ten carbon atoms

Sebacic acid can be sourced from castor oil, which means that nylon 6 10 is partially bio-based—a growing interest point for sustainable plastics. This makes nylon 6 10 more environmentally favorable than some fully fossil-based nylons.

2.3. Polymerization of Nylon 6 10

The production of nylon 6 10 involves a condensation polymerization reaction, where HMDA and sebacic acid react to form long-chain polymers, releasing water as a byproduct. There are typically two methods of polymerization:

- Interfacial polymerization – Useful for thin films and fibers

- Melt polymerization – More common for bulk production of pellets or molded parts

The result is a thermoplastic polymer that can be remelted and reshaped, offering versatility in manufacturing.

What is Nylon 6 10?

2. Nylon 6 10 compared to other types of Nylon

Compared with the above seven nylon polymers, nylon 6 10 has its own advantages, suitable for use in different types of industries. The first advantage of nylon 6 10, compared to nylon 6 and nylon 6 12, is its low moisture absorption, allowing the intact nylon structure to be maintained in wet conditions. Because of this, nylon 6 10 is used to make toothbrush bristles.

Another feature of this polymer is its ability to retain its toughness under temperature changes better than nylon 6 and nylon 6 6. In addition, nylon 6 10 also has good resistance to diluted mineral acids or other chemicals.

3. Key Properties of Nylon 6 10

3.1. Mechanical and Physical Properties

Nylon 6 10 is valued for its balance of flexibility and strength. Key mechanical properties include:

- Tensile strength: Typically ranges from 60–80 MPa

- Flexural modulus: Lower than nylon 6 6, offering more flexibility

- Impact resistance: High, even at low temperatures

- Elongation at break: Can exceed 100%, depending on grade

These attributes make nylon 6 10 suitable for parts requiring mechanical endurance without brittleness.

3.2. Thermal and Chemical Resistance

- Melting point: Around 215–220°C

- Working temperature: Stable up to ~150°C for continuous use

- Chemical resistance: Excellent against aliphatic hydrocarbons, fuels, and oils

- Moisture absorption: Lower than nylon 6 and 6 6, contributing to more stable mechanical performance in humid environments

This combination of features is why nylon 6 10 is used in automotive fuel lines, electrical connectors, and plumbing fittings.

3.3. Comparison with Other Nylons

| Property |

Nylon 6 10 |

Nylon 6 6 |

Nylon 6 |

| Water absorption (24 hrs) |

~1.5% |

~2.5% |

~2.8% |

| Melting point |

215–220°C |

260°C |

220–225°C |

| Bio-based content |

Partial (C10) |

None |

None |

| Flexibility |

High |

Medium |

Medium |

| Surface finish |

Excellent |

Moderate |

Moderate |

Nylon 6 10 stands out for its lower moisture uptake and smoother surface finish, though it’s generally more expensive than the more common nylon 6 and 6 6 grades.

3. Advantages and Limitations of Nylon 6 10

3.1. Key Advantages

Nylon 6 10 offers several compelling benefits:

✅ Lower moisture absorption compared to other nylons

✅ Excellent chemical resistance, especially to fuels and oils

✅ Greater flexibility than nylon 6 6

✅ High surface quality for molded parts

✅ Partially renewable content, offering sustainability value

These properties make it ideal for both technical parts and consumer goods requiring performance and appearance.

3.2. Limitations to Consider

Despite its strengths, nylon 6 10 does have drawbacks:

❌ Higher cost than more common nylons like 6 or 6 6

❌ Slightly lower rigidity, which may be a drawback in load-bearing parts

❌ Less widespread availability, leading to limited grades or suppliers

Choosing nylon 6 10 often comes down to balancing performance, aesthetics, and environmental impact.

4. Applications of Nylon 6 10

4.1. Engineering and Industrial Uses

Nylon 6 10 is widely used in engineering-grade components due to its chemical resistance and dimensional stability. Some typical applications include:

- Fuel lines and tubing in the automotive industry, where flexibility and fuel resistance are critical.

- Gears and bushings, thanks to its low friction and excellent wear resistance.

- Cable ties and fasteners, which benefit from nylon 6 10's toughness and ease of processing.

These applications often involve under-the-hood or fluid-contact environments, where other nylons might degrade or swell due to fuel and moisture exposure.

Some parts in cars such as radiators are made from Nylon 6 10

In addition to the automobile industry, the sports industry also uses this nylon to make parts such as racket frames and bicycle parts. The toughness and lightweight of nylon 6 10 make it the preferred material for the manufacture of these two types of equipment, helping to prolong the life of tools such as badminton or tennis rackets, or reducing the bicycle’s weight, helping athletes to reach the finish line quickly, or help cyclists to train more effectively.

There are parts in a bicycle are made from nylon 6 10

4.2. Consumer and Textile Applications

Beyond industrial use, nylon 6 10 is also found in everyday products:

- Toothbrush bristles: Nylon 6 10 is soft, durable, and has a good mouth feel.

- Combs and brushes: Valued for its glossy finish and strength.

- Textile fibers: Though less common than nylon 6 or 6 6, nylon 6 10 may be blended into fabrics for specific properties such as low water absorption and added stretch.

Its smooth surface finish and light color tone also make it suitable for colored consumer products that require durability with aesthetics.

5. Conclusion

Nylon 6 10 may not be the most common polyamide, but it offers a rare balance of mechanical strength, chemical resistance, and sustainability. Its unique 6–10 carbon monomer structure, low water absorption, and bio-based potential position it as a strong candidate for industries looking beyond traditional nylon 6 or 6 6.

If you're designing components that require performance in harsh environments—or simply looking for a greener nylon option—nylon 6 10 is absolutely worth considering.

6. About EuroPlas Engineering Plastic Compound

At EuroPlas, the company provides polymer nylon solutions in two groups of products: Polyamide (PA6) and Polyamide-66 (PA66) glass fiber compound, and PA6-PA66 blend compound.

PA66, PA6 Glass fiber compound is a mixture of PA resin and glass fiber reinforced. It has great toughness, wear resistance, chemical resistance, high heat deflection temperature, and mechanical strength. Also, the material is stable, electrically insulated, and easy to mold. With PA6-PA66 blend compound, they are the combination of PA6, PA66 resin and elastomer. The most common applications of PA6, PA66 blend compounds are in the automobile and motorcycle industries. This material is frequently used in roller bearings, office equipment, carburetors, exhaust gas control valves, fuel tank lids, and other gear-related components.

Proud to be the world's largest filler masterbatch manufacturer, EuroPlas always offers materials solutions other than filler masterbatch such as bioplastic compound, plastic additives, engineering plastic compound, and bio fillers, therefore helping businesses improve profits and their competitive position in the market. Owning a team of seasoned experts, EuroPlas is ready to listen to the customers’ opinion, thereby offering the most suitable solution. Contact EuroPlas if you have questions, or if you have specific needs about your next project.