Plastic has been a common substance in our everyday life for many years. It is widely used in many sectors, including manufacturing, packaging, and construction. Polyethylene (PE) and Polyethylene Terephthalate are two of the most commonly used forms of plastic (PET). These two polymers have significant variances while being widely used. We shall examine the parallels and discrepancies between Pet vs Pet plastic in this article to provide readers with a thorough grasp of both materials.

Table of Contents

- Introduction

- What is PET?

- What is PE?

- Similarities between Pet vs Polyethylene plastic

- Differences between Pet vs Polyethylene plastic

- Conclusion

- Europlas - the world's leading plastic masterbatch manufacturer

- FAQs

1. Introduction

Because of their cost and durability, PET and polyethylene polymers are widely used in packaging. To make educated choices concerning these two kinds of plastics' uses, it is essential to comprehend the differences between them. We will investigate the similarities and differences between PET and PE plastics in this post and highlight the leading producer of plastic masterbatch, Europlas. You will have a more excellent knowledge of the distinctions between PET and polyethylene by the conclusion of this article, as well as the relevance of selecting the appropriate material for your packaging requirements.

2. What is PET?

PET is a multipurpose thermoplastic polymer often used in packaging to create plastic bottles, containers, and packaging films. It is resistant to impact and unlikely to break because of its strength, lightweight, and transparency. PET is a perfect food and beverage packaging material since it is impermeable to gasses and liquids. The fact that PET is recyclable and can be made into new plastic goods like garments, carpets, and furniture is its finest feature. Also, supermarket retailers prefer PE plastic bags because of their flexibility and low weight.

What is PET?

What is PET?

3. What is PE?

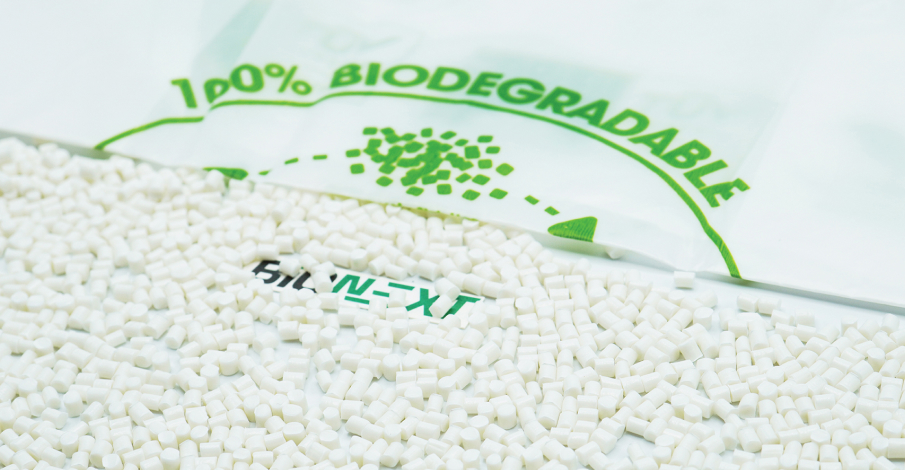

A thermoplastic polymer called polyethylene (PE) is widely used in packaging. It is a versatile substance that may be made in various shapes, including linear low-density polyethylene, high-density polyethylene, and low-density polyethylene (LLDPE). PE is a popular material for creating bags, films, and containers because of its low weight, flexibility, and excellent impact strength. Another benefit of PE is that it can be recycled to make various items, including garbage bags, playground equipment, and plastic lumber.

Construction-related HDPE pipes are a prime example of PE's robustness and resistance to corrosion. Recycling PE allows the manufacturing of plastic lumber and playground equipment, showcasing its adaptability and sustainability.

What is PE?

What is PE?

4. Similarities between Pet vs Polyethylene plastic

There are certain similarities between Pet vs pet plastic, including:

Firstly, they are both widely utilized in the packaging industry due to their low cost and high durability.

Secondly, they are thermoplastic polymers, easily molded into different shapes and forms to meet various purposes.

Lastly, they are both recyclable materials that can be repurposed to produce new plastic products, which helps reduce waste and environmental impact.

For instance, both PET and PE plastics are commonly used in the manufacturing of plastic bottles, such as water bottles and soda bottles. Additionally, they can be recycled to create new plastic products, such as outdoor furniture or synthetic textiles, which helps reduce the amount of waste that ends up in landfills.

5. Differences between Pet vs Polyethylene plastic

Pet vs polyethylene are often found in the mix of plastic materials frequently used in manufacturing and packaging. However, the composition, physical characteristics, uses, and even environmental effects of these two thermoplastics significantly differ from one another. We've created a comparison chart below to better comprehend these differences.

|

|

PET Plastic

|

PE Plastic

|

|

Composition and Chemistructure

|

PET is made by

polymerizing

ethylene glycol

and terephthalic

acid.

|

PE is made from

polymerizing

ethylene.

|

|

Physical Properties

|

PET is a clear,

lightweight, and

strong plastic

that is resistant

to impact,

moisture, and

chemicals.

|

PE is a flexible, waxy, and translucent plastic that is resistant to moisture, chemicals, and impact.

|

|

Application and Use

|

PET is commonly

used for bottles,

jars, packaging

film, and

synthetic fibers.

|

PE is commonly used

for bags, films, pipes,

and molded

products.

|

|

Recycling and

Environmental

Impact

|

PET is recyclable

and can be

turned into new

products, but it

takes a long time

to decompose in

the environment.

|

PE is recyclable and

can be turned into

new products, but it

is not biodegradable

and can contribute

to marine pollution.

|

6. Conclusion

Two plastics that are often utilized in the packaging sector are Pet vs Pe. While they have certain commonalities, they also stand apart in a way that makes them appropriate for various uses. PET is a strong, clear plastic with better gas and moisture barrier properties, despite the fact that PE is more bendable and easier to make. Being a top producer of plastic masterbatches, Europlas provides a selection of premium masterbatches specifically crafted to satisfy clients' demands across various sectors.

These goods include masterbatch chemicals that may improve UV resistance, anti-static capabilities, and color improvement of both Pet vs Pe plastics. By working closely with its clients, Europlas can provide specialized solutions that not only meet their unique needs but also enable them to lessen their environmental impact. Europlas is well-positioned to continue supplying top-notch masterbatch solutions that satisfy the changing demands of the packaging sector because of its constant commitment to sustainability and innovation.

7. Europlas - A world's leading plastic masterbatch manufacturer

Europlas is a world-leading plastic masterbatch manufacturer catering to the ever-growing demand for high-quality plastic compounds. With its wide range of masterbatch solutions, cutting-edge manufacturing facilities, and commitment to sustainable practices, Europlas has established itself as a trusted partner in various industries worldwide.

Their dedication to continuous research and development, collaborative partnerships, and global distribution network has enabled them to provide customized solutions that meet the unique requirements of diverse sectors. Europlas's commitment to quality control, certifications, and industry recognition further solidifies its trusted and reliable masterbatch manufacturer position.

Whether it's enhancing plastic products' colour, strength, or functional properties, Europlas remains at the forefront of innovation, providing top-notch masterbatch solutions. Their customer-centric approach and exceptional customer support ensure clients receive tailored guidance and assistance throughout their journey.

With Europlas, customers can expect a competitive advantage in their respective industries, as the company consistently delivers masterbatch solutions that meet the highest standards of quality, sustainability, and performance.

Partner with Europlas today and experience the difference their world-class masterbatch solutions can make in your plastic manufacturing processes.

Europlas - A world's leading plastic masterbatch manufacturer

Europlas - A world's leading plastic masterbatch manufacturer

8. FAQs

What is the purpose of PET plastic?

PET plastic is often used for synthetic fibers, packaging film, bottles, and jars.

What is the purpose of PE plastic?

Bags, films, pipelines, and molded goods are often made using PE plastic.

Plastics made of PET and PE are recyclable?

Yes, it is possible to recycle both PET and PE plastics.

Is Europlas devoted to the environment and sustainability?

Europlas is dedicated to sustainability and the environment, as seen by the products it offers and the production methods it uses.

If you would like to know more details about our filler masterbatch product in particular, as well as our other masterbatches, please fill out this form or contact us via email/phone number. We are happy to answer all your product questions and concerns!