PETG filament has become increasingly popular in the world of 3D printing and manufacturing. This article delves into its key characteristics, advantages, and the industries where PETG filament is widely used. We will also explore why EuroPlas is a trusted provider of high-quality PETG products.

1. What Is PETG Filament?

PETG stands for Polyethylene Terephthalate Glycol-modified, a thermoplastic polymer that combines the properties of PET (Polyethylene Terephthalate) with the added benefits of glycol. This modification improves the material's durability, flexibility, and impact resistance. By adding glycol during the production process, PETG becomes less brittle, making it more suitable for applications requiring toughness and longevity.

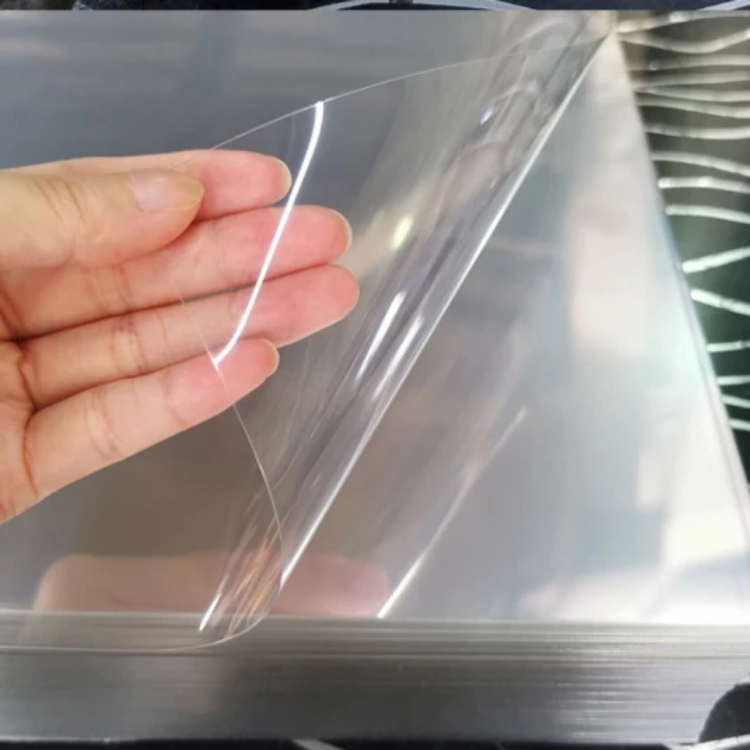

The glycol modification allows PETG to withstand higher and lower temperatures compared to standard PET, while also enhancing its ease of processing. PETG offers excellent clarity and transparency, making it an ideal choice for various applications ranging from food packaging to medical devices and other products that demand both strength and flexibility.

PETG filament stands for Polyethylene Terephthalate Glycol-modified, a plastic material that combines the strength and flexibility of PET with the added durability and workability of glycol. This modification allows the material to be less brittle, more durable, and easier to work with, particularly in applications that require 3D printing.

PETG filament stands for Polyethylene Terephthalate Glycol-modified.

This type of filament is often praised for its high transparency, resilience, and ease of use, making it suitable for both beginners and professionals in the field of 3D printing. Due to its chemical properties, PETG also finds applications in food packaging, medical devices, and automotive parts, where toughness and durability are required.

Key properties include:

Clarity: PETG offers a glass-like transparency, useful in applications requiring visibility of internal components.

Toughness: The filament is highly impact-resistant and less prone to breaking compared to other materials like PLA.

Chemical resistance: PETG can withstand exposure to various chemicals, oils, and solvents, making it ideal for applications in harsher environments.

Printability: It is easy to print with PETG filament as it adheres well to the printing bed, reducing warping and other common printing issues.

2. Advantages Of PETG Filament

PETG filament boasts a range of advantages, making it a top choice for numerous applications. Let’s explore these benefits:

2.1. Strength and Flexibility

PETG is known for its toughness while retaining a certain level of flexibility. This combination makes it ideal for projects requiring both strength and resistance to wear and tear. PETG performs better than PLA, especially in environments where parts might experience stress or mechanical force.

PETG is known for its toughness while retaining a certain level of flexibility.

2.2. Chemical and UV Resistance

One of the key advantages of PETG filament is its resistance to chemicals and UV rays. Unlike PLA, PETG can be used in outdoor applications and environments where exposure to chemicals is common. This makes it suitable for automotive parts, outdoor signage, and laboratory equipment.

2.3. Ease of Use

PETG filament is user-friendly, offering excellent adhesion to the print bed and minimal warping during the printing process. It requires less post-processing compared to materials like ABS and is compatible with a wide range of 3D printers, which is why it’s popular among both beginners and experienced users.

2.4. Aesthetic Qualities

PETG’s glossy finish and transparency make it perfect for display and aesthetic applications. It’s often used in packaging, product displays, and architectural models where a smooth and visually appealing surface is desired.

2.5. Recyclability

PETG is also recyclable, which makes it an eco-friendly alternative to other plastic filaments. This sustainability aspect is particularly valuable in industries focused on reducing environmental impact.

3. Applications of PETG Filament

PETG filament is used in a wide variety of industries thanks to its versatility and strong properties. Let’s take a look at some key applications:

3.1. Prototyping and Manufacturing

Due to its strength and ease of printing, PETG is commonly used for prototyping functional parts that need to endure stress during testing. Engineers and designers prefer PETG for creating accurate prototypes that closely mimic the properties of final production materials.

PETG is commonly used for prototyping functional parts that need to endure stress during testing.

3.2. Medical Devices

PETG’s biocompatibility and sterilizability make it an excellent material for manufacturing medical devices such as syringes, containers, and protective equipment. Its ability to withstand sterilization processes, such as exposure to ethylene oxide or gamma radiation, makes it suitable for medical environments.

3.3. Food and Beverage Packaging

PETG is widely used in the food and beverage industry due to its chemical resistance and food-safe properties. Common uses include bottles, blister packs, and containers that need to maintain both durability and transparency.

3.4. Automotive Industry

In the automotive sector, PETG is used for components like dashboards, light covers, and interior parts. Its UV resistance and chemical stability make it perfect for both interior and exterior components in vehicles.

3.5. Electronics and Consumer Goods

The electronics industry often uses PETG for producing housings and protective covers for various devices. Its durability ensures that electronics are well-protected, while its flexibility and aesthetic finish make it ideal for consumer products such as phone cases and gadget housings.

The electronics industry often uses PETG for producing protective covers.

3.6. Display Models and Architecture

Architects and designers frequently use PETG filament for creating architectural models. Its transparent nature and smooth surface finish make it easy to create realistic models, complete with features like windows and glass panels.

To learn more about how PETG compares to PCTG, read more in our article here. Understanding the differences between these two materials can help you make informed decisions about which filament best suits your specific needs and applications.

4. Conclusion

PETG filament is a highly versatile material that offers a combination of strength, flexibility, and chemical resistance. Its ease of use in 3D printing, combined with its suitability for a wide range of industries including medical, automotive, and packaging, makes it a top choice for manufacturers and hobbyists alike. Moreover, its recyclability adds to its appeal as an environmentally friendly material. For anyone looking for a reliable filament with both functional and aesthetic qualities, PETG is the ideal solution.

5. About EuroPlas

EuroPlas is one of the leading manufacturers of filler masterbatches, specializing in offering high-quality solutions to a wide range of industries. With a deep commitment to innovation and sustainability, our filler masterbatches are designed to enhance the properties of various plastic products, improving performance while reducing production costs.

Our products are used across multiple applications, including packaging, automotive, construction, and consumer goods, helping manufacturers improve the durability, strength, and versatility of their plastic materials. EuroPlas takes pride in providing environmentally friendly solutions that align with the growing global demand for more sustainable and cost-efficient manufacturing.

For more information about how our filler masterbatches can enhance your manufacturing process or to learn more about our full product range, get in touch with EuroPlas today. We’re dedicated to helping you find the right materials to optimize performance, cut costs, and drive sustainability in your operations.