Plastic processing plays a vital role in the global manufacturing industry, as it enables the creation of a diverse range of products used in everyday life, from packaging materials to automotive parts. However, this complex process is not without its challenges. Manufacturers constantly face difficulties that can affect both the quality of the end product and the efficiency of the production process. Issues such as material inconsistencies, machine malfunctions, and environmental concerns pose significant hurdles. In this article, we will delve into the most common challenges in plastic processing and discuss practical approaches to overcoming these obstacles. Additionally, we'll explore how advancements in technology are helping to improve plastic processing techniques, while reducing waste and enhancing sustainability. Finally, we'll introduce EuroPlas, a leader in providing solutions for plastic manufacturers.

1. Challenges in plastic processing

Plastic processing involves several intricate steps, from selecting and preparing raw materials to forming the final product through methods like injection molding, extrusion, or thermoforming. Each stage presents unique challenges that, if not addressed, can lead to defects, inefficiencies, and increased costs. Below are some of the most frequent issues encountered in plastic processing.

1.1 Material inconsistencies

Material inconsistency is one of the most prevalent problems in plastic processing. Polymers can vary in properties such as molecular weight, viscosity, and density, leading to uneven material flow during processing. These inconsistencies can cause a variety of issues, including poor surface finish, dimensional instability, and internal defects like voids or cracks. For industries where precision is critical, such as electronics, automotive, or medical equipment, material inconsistencies can result in product failure and non-compliance with strict industry standards.

Even when using high-quality raw materials, factors such as moisture content, contamination, or improper storage can further exacerbate material inconsistencies, making it difficult to maintain product uniformity across large production runs.

Material inconsistency is one of the most prevalent problems in plastic processing.

Material inconsistency is one of the most prevalent problems in plastic processing.

1.2 Machine malfunctions

Plastic processing machinery, including injection molding machines, extruders, and thermoformers, must operate under high temperatures and pressures to transform raw plastic into the desired shapes. Over time, this continuous operation can cause components like screws, barrels, and heaters to wear out or malfunction. Machine malfunctions can result in production delays, defective products, or even safety hazards in extreme cases.

Regular machine maintenance and part replacements are essential, but unexpected malfunctions can still occur, especially in high-volume production environments. When machines fail, manufacturers often face significant downtime, leading to increased costs and missed delivery deadlines.

1.3 Temperature control issues

Maintaining precise temperature control during plastic processing is crucial for ensuring optimal material flow and product quality. Fluctuations in temperature, whether too high or too low, can cause issues such as poor material adhesion, warping, or incomplete molding. Different polymers require specific temperature ranges for effective processing, and maintaining these parameters is a constant challenge, particularly when dealing with multiple types of plastics in a single production line.

Overheating can degrade the plastic material, leading to a loss of mechanical properties and surface defects, while underheating can result in incomplete melting and poor material distribution. Therefore, precise temperature management is essential for producing high-quality plastic products.

1.4 Environmental impact

The growing global emphasis on sustainability has put pressure on plastic manufacturers to reduce the environmental impact of their operations. Traditional plastic processing methods are energy-intensive and generate significant waste in the form of scrap materials, defective products, and emissions. In response, many manufacturers are looking for ways to minimize energy consumption, reduce waste, and incorporate recycled materials into their production processes.

However, balancing the need for efficient production with environmental responsibility remains a significant challenge. Implementing sustainable practices often requires investing in new technologies and modifying existing processes, which can be costly and time-consuming.

The growing global emphasis on sustainability has put pressure on plastic manufacturers to reduce the environmental impact of their operations.

The growing global emphasis on sustainability has put pressure on plastic manufacturers to reduce the environmental impact of their operations.

1.5 Contamination risks

Contamination is a critical issue in plastic processing, especially when producing items for the food, medical, or pharmaceutical industries. Contaminants, whether from the production environment, raw materials, or machine residues, can compromise product safety and quality. Ensuring a clean production process is vital, but preventing contamination requires stringent quality control measures, including the use of cleanrooms, proper material handling procedures, and regular equipment cleaning.

Even minor contamination can lead to significant product defects or recalls, resulting in financial losses and reputational damage for manufacturers. As such, contamination prevention is a top priority in many plastic processing operations.

2. Approaches to overcome plastic processing challenges

Addressing the challenges in plastic processing requires a strategic approach that combines technological innovations, process optimization, and skilled workforce training. Below are some common approaches that manufacturers can adopt to overcome these obstacles.

2.1 Implementing rigorous quality control

To combat material inconsistencies, manufacturers should implement rigorous quality control measures at every stage of the production process. This includes testing raw materials for properties like melt flow index, viscosity, and mechanical strength before use. Automated monitoring systems can also help track material behavior during processing, allowing operators to make real-time adjustments to ensure consistent quality.

Regular sampling and testing of finished products can help identify defects early, reducing waste and ensuring that only high-quality products reach the market.

To combat material inconsistencies, manufacturers should implement rigorous quality control measures at every stage of the production process.

To combat material inconsistencies, manufacturers should implement rigorous quality control measures at every stage of the production process.

2.2 Preventive maintenance programs

A proactive approach to machine maintenance is essential for avoiding unexpected malfunctions and minimizing downtime. Manufacturers should establish preventive maintenance programs that include routine inspections, part replacements, and machine calibration. This ensures that machinery operates at peak performance and helps prevent costly breakdowns.

Operators should also be trained to identify signs of wear and tear, such as unusual noises, temperature fluctuations, or material buildup, so that they can address issues before they escalate into major problems.

2.3 Advanced temperature control systems

Investing in advanced temperature control systems can help manufacturers maintain the precise thermal conditions required for different polymers. These systems provide real-time temperature monitoring and automatic adjustments, ensuring that the material stays within the optimal processing range. By maintaining consistent temperatures, manufacturers can avoid defects caused by overheating or underheating and improve overall product quality.

2.4 Recycling and waste reduction strategies

To address the environmental impact of plastic processing, many manufacturers are adopting recycling and waste reduction strategies. Closed-loop recycling systems, where scrap material is collected and reprocessed into new products, are becoming increasingly popular. Additionally, energy-efficient machinery and production techniques, such as heat recovery systems and optimized production schedules, can help reduce energy consumption and minimize waste.

Incorporating post-consumer recycled materials into the production process is another approach that manufacturers are using to improve sustainability while meeting customer demands for eco-friendly products.

To address the environmental impact of plastic processing.

To address the environmental impact of plastic processing.

2.5 Cleanroom technology

For industries that require high levels of cleanliness, such as medical devices and food packaging, manufacturers can benefit from using cleanroom technology. Cleanrooms are controlled environments where temperature, humidity, and air quality are regulated to minimize contamination risks. While setting up and maintaining a cleanroom can be costly, it ensures that products meet strict quality and safety standards.

3. Technological innovations in plastic processing

Technological advancements have revolutionized plastic processing, making it more efficient, sustainable, and reliable. Below are some key innovations that are transforming the industry.

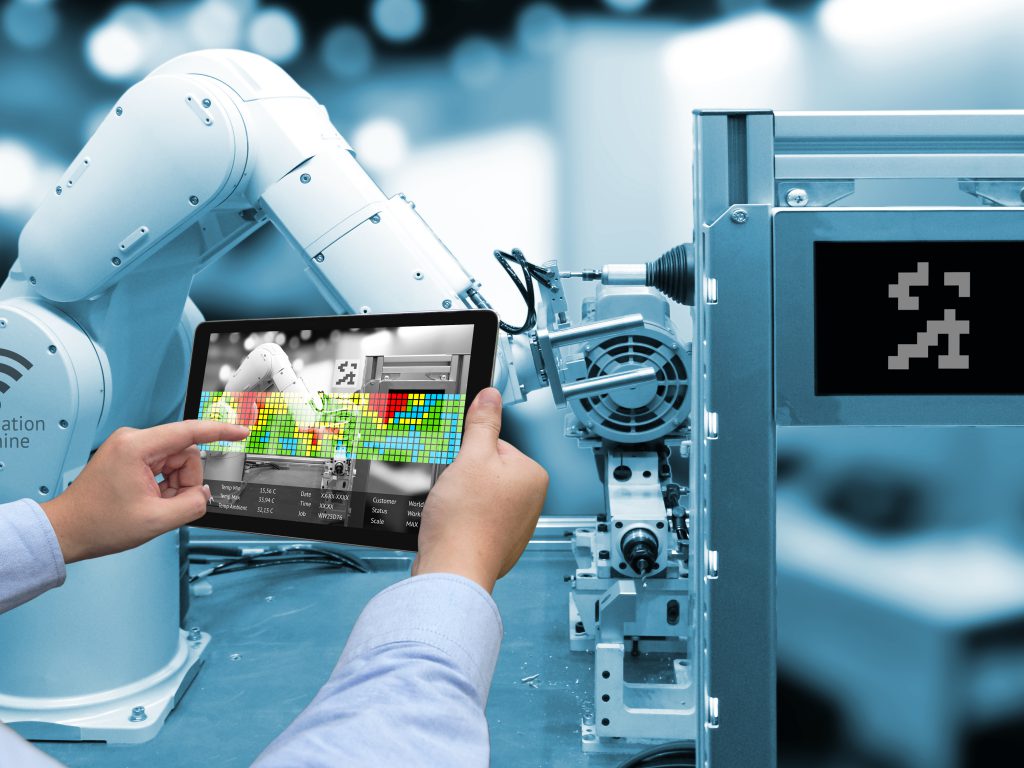

3.1 Automation and robotics

Automation has significantly improved productivity in plastic processing by reducing human error and increasing consistency. Robotic systems can perform repetitive tasks like material handling, machine operation, and quality inspection with precision and speed, reducing labor costs and minimizing the risk of contamination.

Automation has significantly improved productivity in plastic processing by reducing human error and increasing consistency.

Automation has significantly improved productivity in plastic processing by reducing human error and increasing consistency.

3.2 Predictive maintenance

Predictive maintenance technology uses sensors and data analysis to predict when machines are likely to fail, allowing manufacturers to perform maintenance before a breakdown occurs. This reduces downtime, improves machine longevity, and ensures smooth production processes.

3.3 Smart sensors for real-time monitoring

Smart sensors are increasingly being used in plastic processing to provide real-time data on parameters like temperature, pressure, and material flow. This allows operators to make immediate adjustments, ensuring that the process remains within optimal conditions and preventing issues before they affect product quality.

4. Conclusion

Plastic processing is a complex and multifaceted process that presents numerous challenges, from material inconsistencies to machine malfunctions and environmental concerns. However, by implementing proactive measures such as rigorous quality control, preventive maintenance, and advanced technology, manufacturers can overcome these obstacles and achieve efficient, high-quality production. Technological innovations like automation, predictive maintenance, and smart sensors are also helping to enhance the reliability and sustainability of plastic processing operations.

5. About EuroPlas

EuroPlas is a global leader in the production of high-quality

filler masterbatches,

additives, and other plastic raw materials. Our products are designed to help manufacturers overcome common challenges in plastic processing, such as material inconsistencies, contamination, and environmental impact. With a commitment to innovation and sustainability, EuroPlas partners with manufacturers to improve product quality, reduce waste, and enhance production efficiency. Contact us today to learn more about how our solutions can benefit your plastic processing operations.